Product Description

Product Description

A: Product Description

| Commodity Name | double acting hydraulic cylinder, hydraulic cylinder |

| Suitable Model | construction machinery |

| Original | ZheJiang , China |

| Warranty | One year |

| Min of quantity | 1 piece |

| Packing | standard export wooden box or as your require |

| Time of Shipment | Usual 30-60days. Different according the quantity of order. |

| Port of Delivery | HangZhou, China |

Product Parameters

CATALOGUE OF HYDRAULIC CYLINDERS

| NO. | MACHINERY NAME | CYLINDER MODEL | TUBE(mm) | ROD(mm) | STROKE LENGTH(mm) | LOCATING DISTANCE(mm) | WORKING PRESSURE(Mpa) |

| 1 | CANE HARVESTER | 40-22-108 | 40 | 22 | 108 | 352 | 16 |

| 2 | CANE HARVESTER | 40-43-180 | 40 | 43 | 180 | 295 | 16.5 |

| 3 | CANE HARVESTER | 50-25-165 | 50 | 25 | 165 | 440 | 16 |

| 4 | CANE HARVESTER | 63-40-733 | 63 | 40 | 733 | 1120 | 16 |

| 5 | CANE HARVESTER | 75-40-250 | 75 | 40 | 250 | 521 | 16.5 |

| 6 | CANE HARVESTER | 83-60-140 | 83 | 60 | 140 | 525 | 16 |

| 7 | COMBINE HARVESTER | 32-18-123 | 32 | 18 | 123 | 313 | 16 |

| 8 | COMBINE HARVESTER | 50-25-87 | 50 | 25 | 87 | 265 | 16 |

| 9 | COMBINE HARVESTER | 50-25-126 | 50 | 25 | 126 | 816 | 16 |

| 10 | COMBINE HARVESTER | 83-60-150 | 83 | 60 | 150 | 625 | 16 |

| 11 | CORN HARVESTER | 40-22-200 | 40 | 22 | 200 | 367 | 16 |

| 12 | CORN HARVESTER | 40-35-270 | 40 | 35 | 270 | 640 | 16 |

| 13 | CORN HARVESTER | 45-25-200 | 45 | 25 | 200 | 430 | 16 |

| 14 | CORN HARVESTER | 50-25-220 | 50 | 25 | 220 | 439 | 16 |

| 15 | CORN HARVESTER | 50-28-210 | 50 | 28 | 210 | 490 | 16 |

| 16 | CORN HARVESTER | 52-35-190 | 52 | 35 | 190 | 350 | 16 |

| 17 | CORN HARVESTER | 55-35-270 | 55 | 35 | 270 | 739 | 16 |

| 18 | CORN HARVESTER | 55-35-780 | 55 | 35 | 780 | 1030 | 16 |

| 19 | CORN HARVESTER | 55-45-160 | 55 | 45 | 160 | 279 | 16 |

| 20 | CORN HARVESTER | 63-35-621 | 63 | 35 | 621.5 | 1066 | 16 |

| 21 | CORN HARVESTER | 63-45-950 | 63 | 45 | 950 | 1310 | 16 |

| 22 | CORN HARVESTER | 68-50-255 | 68 | 50 | 255 | 764 | 16 |

| 23 | CORN HARVESTER | 75-45-916 | 75 | 45 | 916 | 1320 | 16 |

| 24 | CORN HARVESTER | 25-180 | / | 25 | 180 | 340 | 16 |

| 25 | CORN HARVESTER | 45-185 | / | 45 | 185 | 300 | 16 |

| 26 | CORN HARVESTER | 45-280 | / | 45 | 280 | 795 | 16 |

| 27 | CORN HARVESTER | 45-360 | / | 45 | 360 | 520 | 16 |

| 28 | CORN HARVESTER | 50-155 | / | 50 | 155 | 405 | 16 |

| 29 | CORN HARVESTER | 50-215 | 50 | 215 | 467 | 16 | |

| 30 | CORN HARVESTER | 60-210 | 60 | 210 | 1130 | 16 |

Seals: Hallite, Parker, Merkel, etc.

Painting: anti rust painting

Certificate: ISO9001,SGS, CE, BV, TUV

Shaft diameter: 15mm to 600mm

Model number: double acting or single acting

Stage: Up to 5 level

Process: CNC Lathe Machining, CNC Cleaning Machining Robot welding, Milling

Testing Equipment: digital ultrasonic flow detector, ZEISS metallurgical microscope, ultrasonic thickness gauge, CAAM, Projector, Pin Gauge, etc

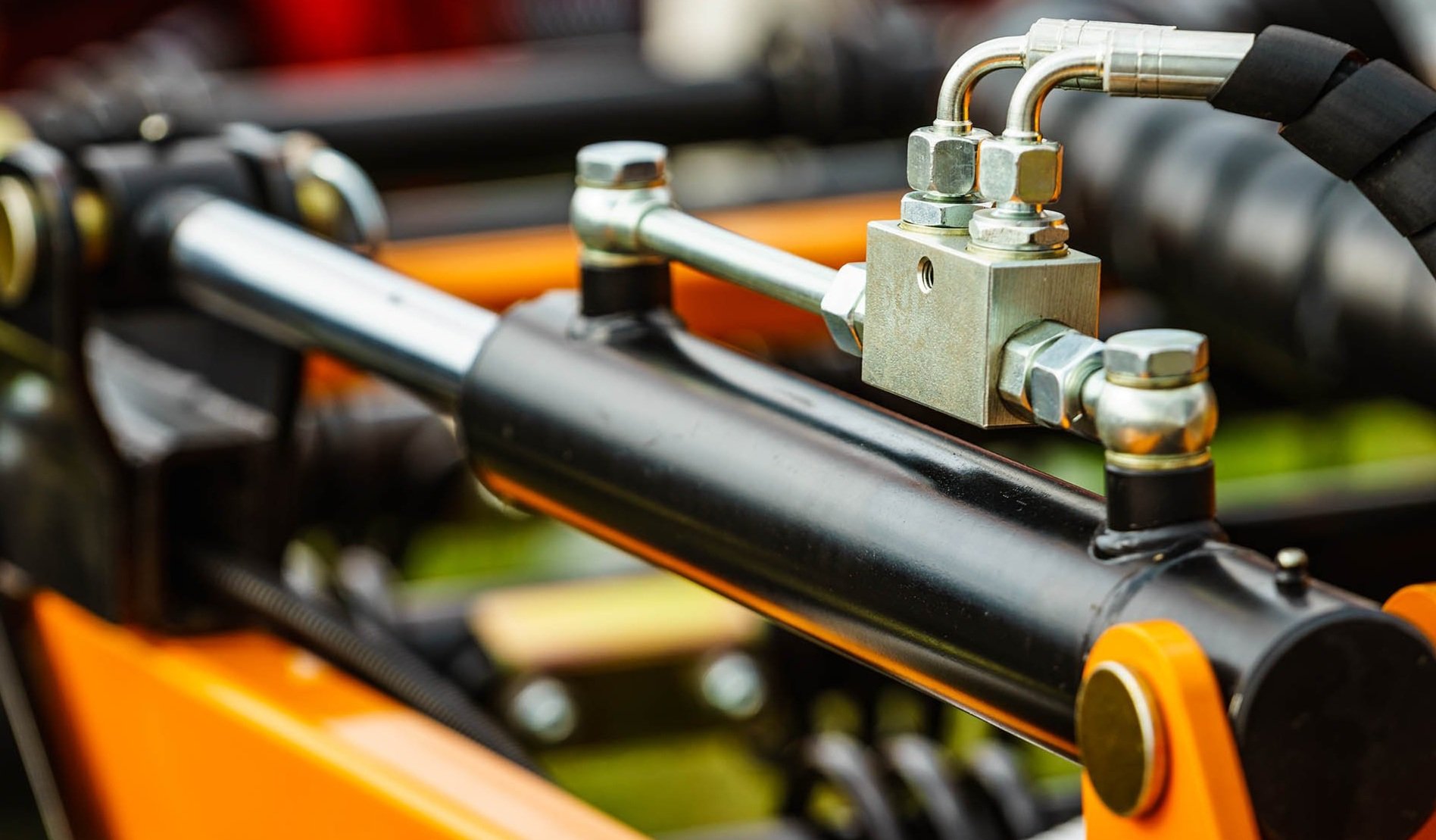

Application: Agricultural, Industrial, Engineer, Construction etc

Keyword: Double Acting Telescopic Hydraulic Cylinder,

After Warranty Service: Online support, Video technical support

Color: blue, red, yellow, green,grey, black, or Client’s Request

Size: Custom

MOQ: 1

Lead time: 30~40days

Customization: customized logo, customized package (min. Order 1 piece)

Shipping: sea freight, land freight, express, air freight

Protection: On-time dispatch is guaranteed

Supply Ability Supply Ability 3000 Pieces per Month

*We can customize and design according to your needs

*We can also produce according to your drawings

*If you need any hydraulic cylinder, please feel free to contact us

Our service/certifications

—CE Certificate of Quality Checked

—Adopt ISO Certificate of Quality Management System

—BV Certificate of Main Products Line verification

—Fast Delivery

—After-sales Service

—24 Hours, 7 Days on-line Service

Company Profile

KENDE is a leading global designer, manufacturer and marketer of hydraulic cylinder,cab, oil tank, counterweight, boom, arm, bucket, chassis, outrigger, pipe, hose, fitting, valve block, tyre, wheel,and other parts. Products are widely used in construction, mining, crane, material handing, automobile, truck, transportation, oil and gas, farm and garden equipment and so on .

We supply a wide range of parts for excavators, loaders, drills, dumpers, forklifts, tractors, trailers, harvestors, cars, buses, trucks and so on. Our products are focused on improved efficiency and life of the machineries and equipments.

Founded in January of 2015, we have become a big group till now which has 3 factories in asia to supply a wide range of products and service for the global customers.

We have the most advanced production equipments and specialized R &D center to assure the highest quality products to customers.

Our vision statement is “Science and technology first, Always with a grateful heart, Walk the world by virtue, Struggle for a better future”

FAQ

1)>. How about your delivery time?

: Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

2)>. What is your terms of price?

: EXW, FOB, CFR, CIF, DDU.

3)> . What is your terms of payment?

: T/T 50% as deposit, and 50% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

4)> . Can you supply a sample freely?

: Sorry, we only can produce the sample with the cost price for you.

5)> Can you produce according to the samples?

: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

6)>. What is your sample policy?

: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

7)>. Do you test all your goods before delivery?

: Yes, we have 100% test before delivery

8)>: How do you make our business long-term and good relationship?

:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, TUV, SGS, BV |

|---|---|

| Pressure: | High Pressure Low Pressure Medium Pressure |

| Work Temperature: | High Temperature Low Temperature Normal Temperat |

| Acting Way: | Double Acting Single Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Customization: |

Available

|

|

|---|

How does a double-acting hydraulic cylinder manage variations in load capacity and weight?

A double-acting hydraulic cylinder is designed to effectively manage variations in load capacity and weight in hydraulic systems. Here’s a detailed explanation:

1. Adjustable Force Output: Double-acting hydraulic cylinders allow for adjustable force output by controlling the hydraulic pressure applied to the cylinder. By adjusting the pressure in the hydraulic system, the force generated by the cylinder can be varied to match the specific load requirements. This feature enables the cylinder to handle variations in load capacity and weight effectively.

2. Mechanical Advantage: Double-acting hydraulic cylinders leverage mechanical advantage to manage variations in load capacity and weight. The cylinder’s design incorporates a larger surface area on the cap end of the piston compared to the rod end. This size difference creates a force amplification effect, allowing the cylinder to exert greater force during the extension stroke. This mechanical advantage enables the cylinder to handle heavier loads and compensate for variations in weight.

3. Pressure Compensation: Double-acting hydraulic cylinders can compensate for variations in load capacity and weight by adjusting the hydraulic pressure in the system. When the load increases, the hydraulic pressure can be increased to generate a higher force output. Conversely, when the load decreases, the pressure can be reduced to match the reduced force requirement. This pressure compensation capability allows the cylinder to adapt to varying load conditions.

4. Position Feedback and Control: To effectively manage variations in load capacity and weight, double-acting hydraulic cylinders can be equipped with position feedback devices and control systems. These devices provide real-time information about the cylinder’s position and can be used to adjust the force output accordingly. By monitoring and controlling the cylinder’s position, the system can respond to changes in load capacity and weight, ensuring optimal performance.

5. Accumulator Integration: Double-acting hydraulic cylinders can be integrated with hydraulic accumulators to manage variations in load capacity and weight. An accumulator is a device that stores hydraulic energy in the form of pressurized fluid. During periods of low load or weight, excess hydraulic energy can be stored in the accumulator. When the load or weight increases, the stored energy can be released to supplement the hydraulic power and provide additional force. This integration helps manage variations in load capacity effectively.

6. System Design and Sizing: Proper system design and sizing play a crucial role in managing variations in load capacity and weight. The hydraulic system, including the double-acting cylinder, should be appropriately sized and selected based on the expected load range. A well-designed system takes into account factors such as the maximum expected load, safety factors, and anticipated variations in weight. By selecting the right cylinder size and ensuring adequate system capacity, variations in load and weight can be effectively managed.

By incorporating these features and considerations, double-acting hydraulic cylinders can effectively manage variations in load capacity and weight, providing reliable and efficient force generation in a wide range of applications.

How does a double-acting hydraulic cylinder contribute to precise force application?

A double-acting hydraulic cylinder plays a crucial role in enabling precise force application. Here’s a detailed explanation:

1. Control over Force Generation: Double-acting hydraulic cylinders provide precise control over the force they generate. By supplying pressurized hydraulic fluid to one side of the cylinder, the piston extends, exerting force in a specific direction. By supplying fluid to the other side, the piston retracts, creating an opposite force. The hydraulic system can be designed with valves, control systems, and pressure regulation mechanisms to adjust and fine-tune the force output. This level of control allows operators to apply the necessary force with precision, whether it’s for lifting, pushing, pulling, or any other task.

2. Adjustable Pressure: The hydraulic system powering the double-acting cylinder allows for adjustable pressure settings. By regulating the hydraulic pressure, operators can precisely control the force output of the cylinder. This adjustability is especially useful when handling delicate or sensitive materials that require a specific amount of force to avoid damage. By fine-tuning the pressure, operators can ensure that the force applied is precisely tailored to the requirements of the task at hand.

3. Smooth and Gradual Force Application: Double-acting hydraulic cylinders facilitate smooth and gradual force application. The hydraulic fluid in the system is incompressible, which means that force is distributed evenly throughout the system. As the hydraulic fluid is pressurized, the force is transmitted to the piston, resulting in a smooth and controlled movement. This allows for gentle and gradual force application, minimizing the risk of sudden or jarring movements that could damage the equipment or the materials being handled.

4. Position and Stroke Control: Double-acting hydraulic cylinders provide precise control over the position and stroke of the piston. The hydraulic fluid can be regulated to stop the piston at specific positions, allowing for precise positioning of loads or equipment. Additionally, the stroke length of the cylinder can be adjusted to control the range of motion. This level of control over position and stroke enables operators to apply force with precision, ensuring accurate and repeatable results in various applications.

5. Feedback and Monitoring: Advanced hydraulic systems can incorporate feedback mechanisms and sensors to monitor and provide real-time information about the force being applied by the double-acting hydraulic cylinder. This feedback allows operators to monitor the force levels, make adjustments if necessary, and ensure that the desired force is being accurately applied. By having access to this information, operators can maintain precise control over force application throughout the operation.

Overall, through control over force generation, adjustable pressure settings, smooth and gradual force application, position and stroke control, as well as feedback and monitoring capabilities, double-acting hydraulic cylinders contribute significantly to precise force application. Their ability to provide controlled and tailored force output makes them essential components in applications where accuracy and precision are paramount.

How does a double-acting hydraulic cylinder differ from a single-acting one?

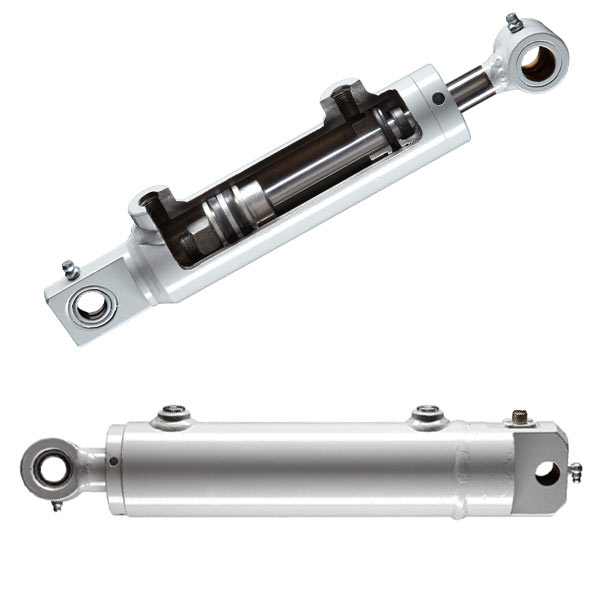

A double-acting hydraulic cylinder and a single-acting hydraulic cylinder differ in their functionality and ability to generate force. Here’s a detailed explanation of the differences:

1. Functionality: A double-acting hydraulic cylinder can generate force in both directions of its stroke, whereas a single-acting hydraulic cylinder can only generate force in one direction.

2. Construction: In a double-acting hydraulic cylinder, there are two hydraulic ports—one connected to the rod end and the other to the cap end of the cylinder. This allows hydraulic fluid to enter and exit both chambers of the cylinder, enabling force generation in both directions. In contrast, a single-acting hydraulic cylinder has only one hydraulic port, typically connected to the cap end. The rod end of a single-acting cylinder is often vented or equipped with a smaller hydraulic port to facilitate the return of the piston.

3. Operation: A double-acting hydraulic cylinder operates by supplying hydraulic fluid to the appropriate ports to extend or retract the piston. By controlling the flow and pressure of the hydraulic fluid, operators can regulate the direction and speed of the piston’s movement, generating pushing and pulling forces. In a single-acting hydraulic cylinder, hydraulic fluid is supplied to the port to extend the piston and generate force in one direction. The return stroke of the piston is accomplished by the force of gravity or an external mechanical load, as there is no hydraulic pressure applied to retract the piston.

4. Applications: Due to their ability to generate force in both directions, double-acting hydraulic cylinders are suitable for applications that require bidirectional force, precise control, and versatility. They are commonly used in tasks such as lifting, pushing, pulling, clamping, and more. Single-acting hydraulic cylinders, on the other hand, are often employed in applications where force is required in only one direction, such as in simple lifting or lowering tasks.

5. Efficiency: Double-acting hydraulic cylinders offer improved efficiency compared to single-acting cylinders in applications that require frequent or continuous bidirectional force. With a double-acting cylinder, the force can be applied in both the extension and retraction strokes, allowing for increased productivity and reduced cycle times.

In summary, the main difference between a double-acting hydraulic cylinder and a single-acting hydraulic cylinder lies in their ability to generate force in one or both directions. While a double-acting cylinder can generate force in both directions, a single-acting cylinder can generate force in only one direction. This distinction impacts their construction, operation, applications, and efficiency in various hydraulic systems.

editor by Dream 2024-04-26