Product Description

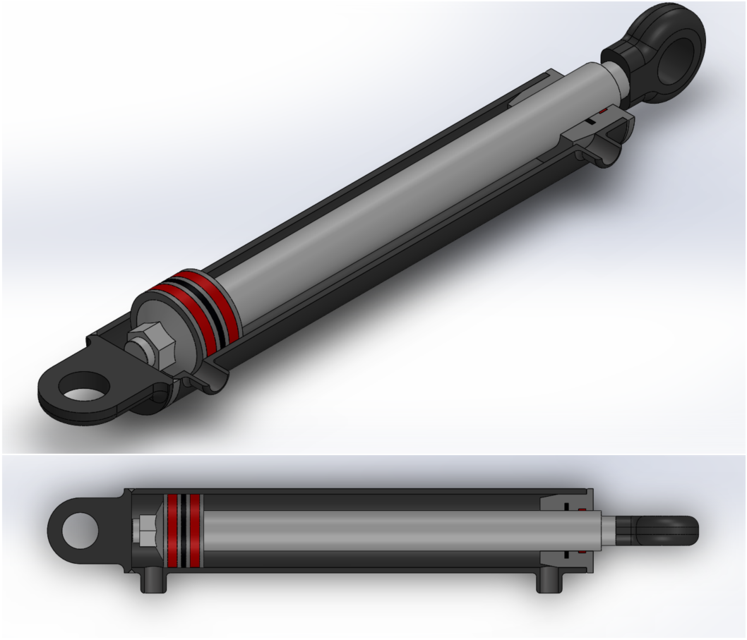

Best Price Double Acting Reciprocating Hydraulic Cylinder for Injection Molding Machine Made in China

Product Specifications:

| Item | Specifications |

| Bore diameter | 80mm-250mm,customizable |

| Bod diameter | 60mm-200mm,customizable |

| Stroke | 500mm-5000mm,customizable |

| Working Pressure | 7-40Mpa,customizable |

| Surface treatment of piston rod | HaHard Chrome Plating,Electroplated Milky White Chromium+Hard Chromium,Nickel Plating+Hard Chromium Plating,High-Velocity Oxygen-Fuel CrC NiC,Ceramic Coating,Nitriding,Laser Cladding |

| Work Pressure | Maximum 38MPa,Customizable |

| Material | High tensile cold drawn tube, precision honed for extended seal life |

| Mounting | Earring,Flange,Clevis.Foot,Trunnion,Customizable |

| Seal Type | Parker,NOK, Hallite GAPI or as customer’s requirement |

| Warrenty | 18 months |

| MOQ | 1pcs |

| Production Time | Based on order quantity.normally 30-40 days. |

| Certification | ISO9001,CE, SGS |

| Colour | Red,White,Pink,Yellow,Bule,etc,Customizable |

| Packaging | metal case,plywood case,carton or as requirement |

| Service | OEM & ODM |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer |

Product Display:

Appliactions:Industrial Engineering,Dual-plated Injection Molding Machine.

Mounting Method:

Our Factory:

Inspection Process:

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes the measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Inspection of Mechanical Properties of Raw Materials

Process Material Inspection

Final Function Testing

Packing & Delivery:

About US:

Our Certificate

ZheJiang Tianjian Hydraulic Technology Co.,Ltd is specializing in the production of various types of hydraulic cylinders as well as cylinder barrel, piston cylinder and other cylinder accessories.

As a highly specialized manufacturer of hydraulic cylinders, tianjian provides design optimization solutions and reliable products to many customers at home and abroad. No matter in construction machinery, railway bridge machinery, port ship machinery, metallurgy and mining machinery, oil and light industry machinery, special vehicles and other industries, tianjian can provide various standard and non-standard hydraulic cylinder design optimization schemes and products according to users’ requirements, and provide integrated services for perfection and quality.

If possible, when contact with us, please apply information as below

|

Bore |

Rod |

Stroke |

Work Pressure |

Mounting |

Work environment |

|

|

|

|

|

|

|

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes.

And if you have samples, we can manufacture according to your samples after sending to us.

Welcome to our factory if you have any time.

Your satisfaction is our biggest motivation.

Now, you can contact with us for any question or inquiry.

FAQ:

1, What does your company do?

A: we are a supplier of high quality hydraulic products including Hydraulic Cylinder, Hydraulic Motor, Hydraulic Power Pack, Hydraulic station and other Hydraulic components.

2, Are you a manufacture or a trading company?

A: We are a manufacturer.

3, What certificate do you have?

A: All our factories are ISO certificated. And our main suppliers of materials and parts are with CE, RoHS, CSA and UL certificates.

4, How long is your delivery time?

A: The delivery time depends on different products and quantity. The cylinder usually need about 45-60 days and the Motor need about 30-50 days.

5, Can you make parts as customer’s requirement or drawing?

A: Yes, we can OEM for you as your drawings. Our engineer also can give you professional support for technical suggestions.

6, What kind of payment terms do you accept?

A: We prefer T/T through bank. 30% when order is confirmed and 70% before shipment. L/C is also acceptable for amount over 20,000USD.

7, What is your warranty policy?

A: All our products are warranted for 1 full year from date of delivery against defects in materials and workmanship. This warranty does not cover parts that are worn out through the course of normal operation or are damaged through negligence. We serious remind that unclean hydraulic oil will definitely cause damage to your Hydraulic components. And this damage is not included in the warranty range. So we strongly suggest you to use new clean oil or make sure the system oil are clean when using our parts

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | High Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 1100/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can double-acting hydraulic cylinders be applied in both mobile and stationary machinery?

Yes, double-acting hydraulic cylinders can be applied in both mobile and stationary machinery. Here’s a detailed explanation:

1. Mobile Machinery: Double-acting hydraulic cylinders find extensive use in various types of mobile machinery. These include construction equipment such as excavators, loaders, and bulldozers, where hydraulic cylinders are utilized for tasks like lifting, digging, and pushing. Agricultural machinery such as tractors, harvesters, and sprayers also employ hydraulic cylinders for functions like raising and lowering attachments, steering, and operating implements. Additionally, hydraulic cylinders are employed in material handling equipment, such as forklifts and cranes, for lifting, lowering, and moving heavy loads. The ability of double-acting hydraulic cylinders to generate bi-directional force and provide precise control makes them well-suited for the dynamic and versatile requirements of mobile machinery.

2. Stationary Machinery: Double-acting hydraulic cylinders are equally applicable in stationary machinery across various industries. In industrial manufacturing, hydraulic cylinders are used in presses, machine tools, and assembly equipment for tasks like clamping, pressing, and forming. They are also employed in the mining and quarrying industry for equipment such as rock crushers and conveyors, providing force for crushing, conveying, and material handling operations. Stationary hydraulic lifts and platforms, such as scissor lifts or dock levelers, rely on hydraulic cylinders for vertical movement and positioning. The versatility and controllability of double-acting hydraulic cylinders make them suitable for precise and reliable operation in stationary machinery.

3. Adaptability: Double-acting hydraulic cylinders offer adaptability that allows them to be applied in both mobile and stationary machinery. They can be designed and manufactured to meet specific requirements, such as different stroke lengths, bore sizes, and mounting configurations, ensuring compatibility with a wide range of applications. Hydraulic systems, including double-acting cylinders, can also be integrated into both mobile and stationary machinery designs, providing a common and standardized power transmission solution. This adaptability enables the use of double-acting hydraulic cylinders in diverse machinery across various industries.

4. Maintenance and Service: Double-acting hydraulic cylinders can be maintained and serviced in both mobile and stationary machinery. Regular maintenance activities such as seal replacement, fluid checks, and lubrication can be performed to ensure optimal performance and longevity. In the case of repairs or component replacements, hydraulic cylinders can be disassembled, repaired, or replaced as needed, regardless of whether they are installed in mobile or stationary machinery.

Given their versatility, adaptability, and maintenance capabilities, double-acting hydraulic cylinders are widely employed in both mobile and stationary machinery, meeting the demanding requirements of diverse industries.

Can double-acting hydraulic cylinders be integrated into manufacturing machinery for pressing and clamping?

Yes, double-acting hydraulic cylinders are commonly integrated into manufacturing machinery for pressing and clamping operations. Here’s a detailed explanation:

1. Pressing Operations: Double-acting hydraulic cylinders are widely used in manufacturing machinery for pressing applications. These cylinders provide the necessary force to press objects together, such as joining components or shaping materials. Hydraulic presses equipped with double-acting cylinders can generate high forces consistently and precisely. The bidirectional force generation of double-acting cylinders allows for controlled pressing in both the extending and retracting strokes, making them suitable for a wide range of pressing tasks in industries such as automotive, aerospace, and metal fabrication.

2. Clamping Operations: Double-acting hydraulic cylinders are also well-suited for clamping operations in manufacturing machinery. Clamping involves holding objects securely in place during various processes, such as machining, welding, or assembly. Hydraulic clamps utilizing double-acting cylinders provide reliable and strong clamping force. The ability to generate force in both directions allows for secure clamping during both the clamping and unclamping phases. This ensures the stability and safety of workpieces during manufacturing operations, preventing movement or misalignment.

3. Force and Stroke Control: Double-acting hydraulic cylinders offer precise control over force and stroke, enhancing their effectiveness in pressing and clamping applications. The flow rate and pressure of the hydraulic fluid can be adjusted using valves and control mechanisms, allowing operators to regulate the force applied by the cylinder. Additionally, the stroke length of the cylinder can be controlled, enabling precise positioning and adjustment to accommodate different workpiece sizes and shapes.

4. Customization and Integration: Double-acting hydraulic cylinders can be customized and integrated into manufacturing machinery to meet specific pressing and clamping requirements. Manufacturers can design cylinders with varying sizes, capacities, and mounting options to fit the machinery and application needs. The modular nature of hydraulic systems allows for easy integration and interchangeability of cylinders, ensuring compatibility with existing manufacturing equipment.

5. Safety Features: Manufacturing machinery incorporating double-acting hydraulic cylinders often incorporates safety features to ensure safe operation during pressing and clamping processes. These may include pressure relief valves, emergency stop mechanisms, and safety interlocks. These features help protect operators, prevent excessive forces or unexpected movements, and provide fail-safe operation.

Given their suitability for pressing and clamping operations, precise force and stroke control, customization and integration capabilities, as well as the inclusion of safety features, double-acting hydraulic cylinders are widely integrated into manufacturing machinery. Their reliable performance and versatility make them essential components in achieving efficient and accurate pressing and clamping processes in various manufacturing industries.

What industries commonly use double-acting hydraulic cylinders in their equipment?

Double-acting hydraulic cylinders are widely used across various industries where controlled linear force is required. Here’s a detailed explanation of the industries that commonly utilize double-acting hydraulic cylinders in their equipment:

1. Manufacturing and Machinery: The manufacturing and machinery industries extensively use double-acting hydraulic cylinders in equipment such as hydraulic presses, material handling systems, assembly lines, robotics, and automation systems. These cylinders provide the necessary force for precise movement, positioning, and operation of components and machinery.

2. Construction and Earthmoving: In the construction and earthmoving sector, double-acting hydraulic cylinders are found in equipment like excavators, backhoes, loaders, bulldozers, cranes, and concrete pumps. They enable the controlled lifting and lowering of heavy loads, extension and retraction of booms and arms, and operation of various hydraulic attachments.

3. Mining and Extraction: Double-acting hydraulic cylinders play a crucial role in mining operations. They are used in equipment such as hydraulic shovels, loaders, crushers, and drilling rigs. These cylinders provide the force necessary for excavation, transportation, and processing of minerals and ores.

4. Agriculture and Farming: In the agricultural sector, double-acting hydraulic cylinders are utilized in machinery and equipment such as tractors, harvesters, sprayers, loaders, and hydraulic implements. They enable functions like lifting and lowering of implements, controlling hydraulic systems for precise operation, and powering attachments such as plows, mowers, and loaders.

5. Automotive and Transportation: Double-acting hydraulic cylinders are employed in various automotive and transportation applications. They are found in vehicle suspension systems, steering mechanisms, hydraulic brakes, dump trucks, garbage trucks, and lifting platforms. These cylinders provide the necessary force for controlled movement, stability, and safety.

6. Aerospace and Aviation: The aerospace and aviation industries utilize double-acting hydraulic cylinders in aircraft landing gear systems, wing flaps, control surfaces, and cargo doors. These cylinders provide the force required for smooth and controlled movement, ensuring safe and efficient operation of aircraft.

7. Marine and Offshore: In the marine and offshore industries, double-acting hydraulic cylinders are used in ship steering systems, hatch covers, cranes, winches, and offshore drilling equipment. They enable precise control of movements and operations in challenging marine environments.

8. Energy and Power Generation: Double-acting hydraulic cylinders are employed in power generation equipment such as hydroelectric turbines and gates, wind turbine pitch systems, and steam turbine control systems. They enable the precise control of mechanical components and the generation of force in both directions.

These are some of the major industries where double-acting hydraulic cylinders are commonly used. However, their versatility and ability to provide bidirectional force make them applicable in many other sectors that require controlled linear force in their equipment and machinery.

editor by CX 2024-04-12