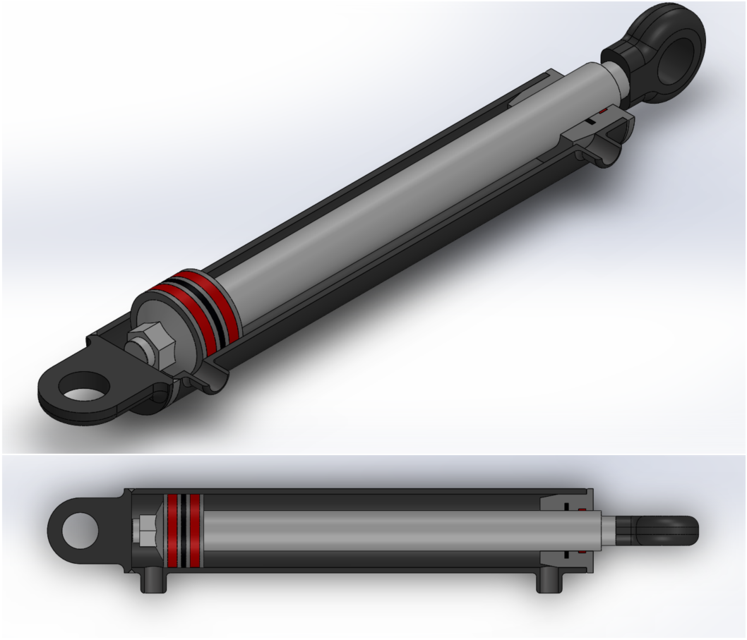

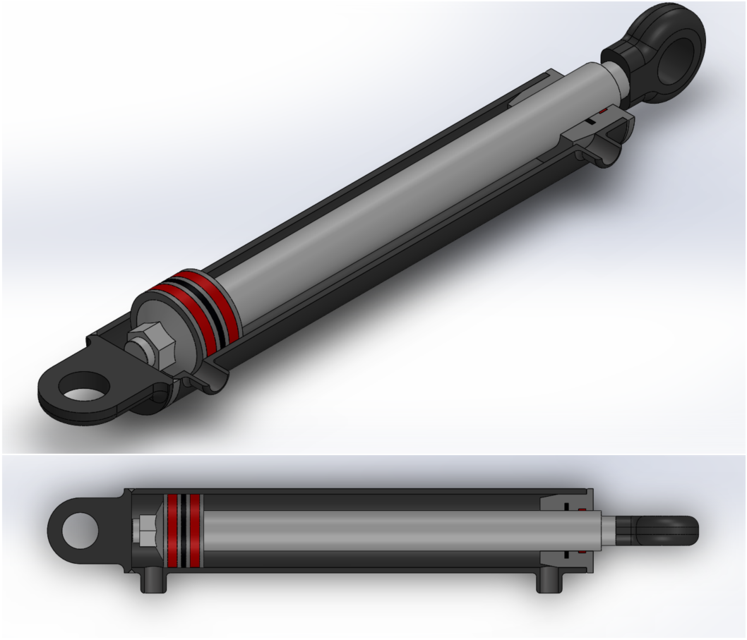

Product Description

Product Description

HangZhou CHINAMFG manufacturing capabilities are a vital component of our business and at the heart of what we do. Our in-house engineering team, manufacturing and quality systems were designed to ensure that we build only the best for our customers; guaranteeing the most appropriate design features and quality product materials for your application. We can also incorporate load holding valves, linear position transducers and a wide range of mounting options. Custom paint and packaging options are also available. 3D CAD models are available CHINAMFG request.

Wide variety of custom cylinders are manufactured, including CHINAMFG cylinders (both single and double acting), single and double acting telescopic (small and large bore), double end cylinders, piggyback design, mill type cylinders, tie rod cylinders, accumulators, marine grade steering cylinders, and standard dimension welded product lines.

Product Parameters

| Max | Min | |

| HydroCylinder bore: | 280 mm | 10 mm |

| Piston Rod Diameter: | 280 mm | 10 mm |

| Retract Length: | 3500 mm | 50 mm |

| Stretch Length(Single stage cylinder): | 6500 mm | 60 mm |

| Stretch Length(Dual stage cylinder): | 12500 mm | 60 mm |

| Working Pressure: | 4500PSI | 1000PSI |

Detailed Photos

Mounting

Factory and Equipments

Packaging & Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does a double-acting hydraulic cylinder handle variations in environmental conditions?

A double-acting hydraulic cylinder is designed to handle variations in environmental conditions effectively. Here’s a detailed explanation:

1. Sealing Mechanism: Double-acting hydraulic cylinders are equipped with sealing mechanisms that help protect the internal components from environmental elements. The cylinder is typically sealed with high-quality seals and gaskets that prevent the ingress of contaminants such as dirt, dust, and moisture. This sealing mechanism helps maintain the integrity of the hydraulic system and ensures reliable operation even in challenging environmental conditions.

2. Corrosion Resistance: Double-acting hydraulic cylinders are often constructed from materials that offer excellent corrosion resistance. Common materials used include stainless steel, chrome-plated steel, or other corrosion-resistant alloys. These materials are chosen to withstand exposure to humid or corrosive environments, such as marine applications or outdoor equipment exposed to weather conditions. The corrosion resistance of the cylinder components ensures its durability and performance over an extended period, even in harsh environmental conditions.

3. Temperature Tolerance: Double-acting hydraulic cylinders are designed to handle variations in temperature effectively. The internal components, such as seals and fluids, are selected to withstand a broad temperature range. Specialized seals and hydraulic fluids can be used to maintain proper performance in extreme heat or cold. Additionally, the cylinder’s design may incorporate temperature compensation features to accommodate thermal expansion and contraction, ensuring consistent and reliable operation across different temperature conditions.

4. Contaminant Filtration: Hydraulic systems that utilize double-acting cylinders often incorporate filtration systems to remove contaminants from the hydraulic fluid. Filtration helps prevent the accumulation of particles that can cause wear and damage to the cylinder components. By maintaining clean hydraulic fluid, the cylinder can operate optimally and handle variations in environmental conditions without compromising performance or longevity.

5. Protective Coatings: In certain applications where additional protection is required, double-acting hydraulic cylinders can be coated with protective materials. These coatings provide an extra layer of defense against environmental factors, such as chemical exposure or abrasive particles. Protective coatings can enhance the cylinder’s resistance to wear, corrosion, and other detrimental effects caused by specific environmental conditions.

6. Compatibility with Environmental Sealing: Depending on the specific application and environmental conditions, double-acting hydraulic cylinders can be integrated with environmental sealing measures. For example, in marine or underwater applications, the cylinder can be designed with additional sealing features to prevent water ingress. Such sealing measures ensure that the cylinder operates reliably and safely in challenging environments.

By incorporating sealing mechanisms, corrosion-resistant materials, temperature tolerance, contaminant filtration, protective coatings, and compatibility with environmental sealing, double-acting hydraulic cylinders can effectively handle variations in environmental conditions. This robust design allows them to operate reliably and maintain performance in diverse applications and challenging environments.

How does a double-acting hydraulic cylinder handle variations in hydraulic hose technology?

A double-acting hydraulic cylinder can accommodate variations in hydraulic hose technology. Here’s a detailed explanation:

1. Connection Flexibility: Double-acting hydraulic cylinders feature versatile connection options, allowing them to adapt to different hydraulic hose technologies. The cylinder typically has threaded ports or flanges designed to accept various types of hydraulic fittings. This flexibility enables the connection of different types of hydraulic hoses, including those with variations in size, material, and connection method.

2. Pressure and Flow Compatibility: Hydraulic hose technology has evolved to provide compatibility with a wide range of pressure and flow requirements. Double-acting hydraulic cylinders can handle these variations by being designed and manufactured to withstand different pressure ratings. The cylinder is selected or customized based on the system’s maximum operating pressure, ensuring its capability to handle the specific hydraulic hose technology being used. Similarly, the cylinder’s internal design and dimensions are optimized to accommodate the required flow rate, ensuring efficient operation.

3. Sealing Mechanisms: Double-acting hydraulic cylinders incorporate sealing mechanisms to ensure the integrity of the hydraulic system, regardless of the specific hose technology being employed. The cylinder is equipped with seals, such as O-rings or lip seals, that create a reliable barrier against fluid leakage. These seals are designed to accommodate variations in hose technology, providing a secure and leak-free connection between the hydraulic cylinder and the hydraulic hoses.

4. Compatibility with Hose Materials: Hydraulic hoses are available in different materials, including rubber, thermoplastic, and metal. Double-acting hydraulic cylinders are designed to be compatible with a wide range of hose materials. The cylinder’s construction and internal components are selected and engineered to withstand the characteristics of different hose materials, such as their flexibility, temperature resistance, and chemical compatibility. This ensures that the hydraulic cylinder can operate seamlessly with various hose technologies, providing reliable and efficient force generation.

5. Customization and Adaptability: Double-acting hydraulic cylinders can be customized and adapted to specific hydraulic hose technologies. They can be designed with different port sizes, thread types, or flange configurations to match the specific requirements of the hydraulic hoses being used. This adaptability allows for easy integration and ensures a secure and efficient hydraulic connection between the cylinder and the hoses, regardless of any variations in hose technology.

Overall, the connection flexibility, pressure and flow compatibility, sealing mechanisms, compatibility with hose materials, as well as customization and adaptability of double-acting hydraulic cylinders enable them to handle variations in hydraulic hose technology. This ensures the reliable and efficient operation of hydraulic systems, regardless of the specific hose technology employed.

What industries commonly use double-acting hydraulic cylinders in their equipment?

Double-acting hydraulic cylinders are widely used across various industries where controlled linear force is required. Here’s a detailed explanation of the industries that commonly utilize double-acting hydraulic cylinders in their equipment:

1. Manufacturing and Machinery: The manufacturing and machinery industries extensively use double-acting hydraulic cylinders in equipment such as hydraulic presses, material handling systems, assembly lines, robotics, and automation systems. These cylinders provide the necessary force for precise movement, positioning, and operation of components and machinery.

2. Construction and Earthmoving: In the construction and earthmoving sector, double-acting hydraulic cylinders are found in equipment like excavators, backhoes, loaders, bulldozers, cranes, and concrete pumps. They enable the controlled lifting and lowering of heavy loads, extension and retraction of booms and arms, and operation of various hydraulic attachments.

3. Mining and Extraction: Double-acting hydraulic cylinders play a crucial role in mining operations. They are used in equipment such as hydraulic shovels, loaders, crushers, and drilling rigs. These cylinders provide the force necessary for excavation, transportation, and processing of minerals and ores.

4. Agriculture and Farming: In the agricultural sector, double-acting hydraulic cylinders are utilized in machinery and equipment such as tractors, harvesters, sprayers, loaders, and hydraulic implements. They enable functions like lifting and lowering of implements, controlling hydraulic systems for precise operation, and powering attachments such as plows, mowers, and loaders.

5. Automotive and Transportation: Double-acting hydraulic cylinders are employed in various automotive and transportation applications. They are found in vehicle suspension systems, steering mechanisms, hydraulic brakes, dump trucks, garbage trucks, and lifting platforms. These cylinders provide the necessary force for controlled movement, stability, and safety.

6. Aerospace and Aviation: The aerospace and aviation industries utilize double-acting hydraulic cylinders in aircraft landing gear systems, wing flaps, control surfaces, and cargo doors. These cylinders provide the force required for smooth and controlled movement, ensuring safe and efficient operation of aircraft.

7. Marine and Offshore: In the marine and offshore industries, double-acting hydraulic cylinders are used in ship steering systems, hatch covers, cranes, winches, and offshore drilling equipment. They enable precise control of movements and operations in challenging marine environments.

8. Energy and Power Generation: Double-acting hydraulic cylinders are employed in power generation equipment such as hydroelectric turbines and gates, wind turbine pitch systems, and steam turbine control systems. They enable the precise control of mechanical components and the generation of force in both directions.

These are some of the major industries where double-acting hydraulic cylinders are commonly used. However, their versatility and ability to provide bidirectional force make them applicable in many other sectors that require controlled linear force in their equipment and machinery.

editor by CX 2024-04-04