Product Description

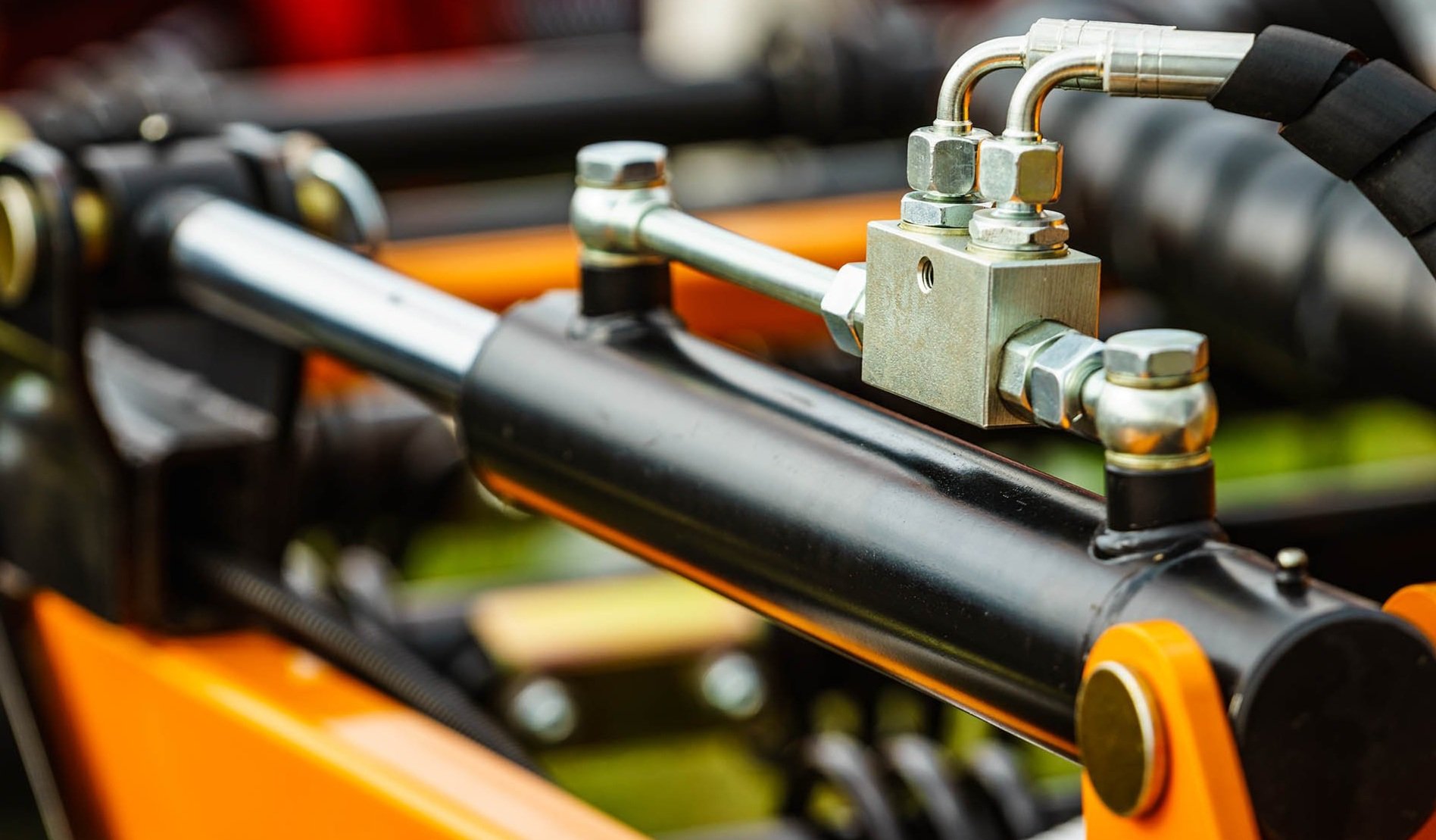

HYDRAULIC CYLINDER

Widely used in equipment for Construction, Coal&mine, Agriculture , Aerial work table and Environmental sanitation etc.

| Features | customized hydraulic cylinder |

| Bore Diameter | 2′-50’/50-1500mm |

| Rod Diameter | 1′ – 60’/25 -1000 mm |

| Wall Thickness | 0.1′-4’/3-100 mm |

| Max Stroke | 366’/9280 mm |

| Max Pressure | 9600 psi/600 bar |

| Test Pressure | 14500 psi/1000 bar |

| Material | 20#,40#,45#,16Mn,27SiMn,etc |

| Seal Kits | Hallite, Parker, NOK, SKF, DICHTOMATIK, Trelleborg, Merkel |

| Dimensional Accuracy | H7-H11 |

| Bore Roughness | Ra 0.4-1.6mm |

| Coating | hard chrome |

| Purpose | engineering, Coal &mining, agricultural machinery, environmental sanitation |

| OEM/ODM | Yes |

| MOQ | 1 Piece |

| Certificates | ISO9001,CE, CCS |

Q1. Are you a manufacturer?

Yes, we have manufactured hydraulic cylinders for over 30 years. They are widely used in Engineers, Coal&mine, Agriculture and Environmental Sanitation etc.

Q2. Do your products come with a warranty?

Yes, we have 1 year warranty.

Q3. Can we customize our products from you?

Yes, actually 70% of our products are customized for our clients. You just need to let us know your demand (specifications &drawing is better), and we shall realize them for you.

Q4. How do you deliver the products?

By sea, by plane, or by couriers.

Q5. How many days the samples can be finished, And how about the mass production?

Generally 5-7days for samples making. The lead time of mass production will depend on quality, production art and so on. Generally 35days.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | -40~120 |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Structure: | Piston Type |

| Customization: |

Available

|

|

|---|

How does a double-acting hydraulic cylinder manage variations in load capacity and weight?

A double-acting hydraulic cylinder is designed to effectively manage variations in load capacity and weight in hydraulic systems. Here’s a detailed explanation:

1. Adjustable Force Output: Double-acting hydraulic cylinders allow for adjustable force output by controlling the hydraulic pressure applied to the cylinder. By adjusting the pressure in the hydraulic system, the force generated by the cylinder can be varied to match the specific load requirements. This feature enables the cylinder to handle variations in load capacity and weight effectively.

2. Mechanical Advantage: Double-acting hydraulic cylinders leverage mechanical advantage to manage variations in load capacity and weight. The cylinder’s design incorporates a larger surface area on the cap end of the piston compared to the rod end. This size difference creates a force amplification effect, allowing the cylinder to exert greater force during the extension stroke. This mechanical advantage enables the cylinder to handle heavier loads and compensate for variations in weight.

3. Pressure Compensation: Double-acting hydraulic cylinders can compensate for variations in load capacity and weight by adjusting the hydraulic pressure in the system. When the load increases, the hydraulic pressure can be increased to generate a higher force output. Conversely, when the load decreases, the pressure can be reduced to match the reduced force requirement. This pressure compensation capability allows the cylinder to adapt to varying load conditions.

4. Position Feedback and Control: To effectively manage variations in load capacity and weight, double-acting hydraulic cylinders can be equipped with position feedback devices and control systems. These devices provide real-time information about the cylinder’s position and can be used to adjust the force output accordingly. By monitoring and controlling the cylinder’s position, the system can respond to changes in load capacity and weight, ensuring optimal performance.

5. Accumulator Integration: Double-acting hydraulic cylinders can be integrated with hydraulic accumulators to manage variations in load capacity and weight. An accumulator is a device that stores hydraulic energy in the form of pressurized fluid. During periods of low load or weight, excess hydraulic energy can be stored in the accumulator. When the load or weight increases, the stored energy can be released to supplement the hydraulic power and provide additional force. This integration helps manage variations in load capacity effectively.

6. System Design and Sizing: Proper system design and sizing play a crucial role in managing variations in load capacity and weight. The hydraulic system, including the double-acting cylinder, should be appropriately sized and selected based on the expected load range. A well-designed system takes into account factors such as the maximum expected load, safety factors, and anticipated variations in weight. By selecting the right cylinder size and ensuring adequate system capacity, variations in load and weight can be effectively managed.

By incorporating these features and considerations, double-acting hydraulic cylinders can effectively manage variations in load capacity and weight, providing reliable and efficient force generation in a wide range of applications.

Can double-acting hydraulic cylinders be used in agricultural machinery for various tasks?

Yes, double-acting hydraulic cylinders are commonly used in agricultural machinery for a variety of tasks. Here’s a detailed explanation:

1. Lifting and Lowering Implements: Agricultural machinery often requires the lifting and lowering of implements such as plows, cultivators, and seeders. Double-acting hydraulic cylinders can provide the necessary force to raise and lower these implements smoothly and efficiently. By supplying pressurized hydraulic fluid to one side of the cylinder, the implement is lifted, and by supplying fluid to the other side, it is lowered. The bi-directional force generation of double-acting cylinders allows for precise control over the height and position of the implements, enabling efficient agricultural operations.

2. Tilting and Positioning: Double-acting hydraulic cylinders can also be used for tilting and positioning tasks in agricultural machinery. For example, in a front-end loader or a combine harvester, hydraulic cylinders are employed to tilt the loader bucket or the cutting platform, allowing for easy loading or harvesting on uneven terrain. The cylinders provide the necessary force to adjust the angle and position of the equipment, enhancing productivity and maneuverability.

3. Steering and Braking: Agricultural machinery, such as tractors and self-propelled harvesters, requires effective steering and braking systems for safe and precise operation. Double-acting hydraulic cylinders can be utilized in these systems to control the movement of steering mechanisms or braking mechanisms. By converting hydraulic pressure into mechanical force, the cylinders enable responsive steering and reliable braking, ensuring operator control and safety in various agricultural tasks.

4. Actuating Hydraulic Valves: Agricultural machinery often incorporates hydraulic systems with multiple valves for controlling the flow of fluids to different components. Double-acting hydraulic cylinders can actuate these valves, allowing for precise control over the functions of the machinery. By extending and retracting the cylinder’s piston, operators can open or close specific valves, regulating the flow of hydraulic fluid and directing it to the desired components or functions.

5. Load Handling and Manipulation: Agricultural machinery frequently involves load handling and manipulation tasks, such as baling, lifting and transporting heavy loads, or operating hydraulic arms for loading and unloading materials. Double-acting hydraulic cylinders provide the necessary force for these tasks, enabling efficient load handling and manipulation. The cylinders can be integrated into lifting mechanisms, arms, or other load-bearing structures, allowing for controlled lifting, lowering, and holding of various agricultural loads.

Given their capabilities in lifting and lowering implements, tilting and positioning, steering and braking, actuating hydraulic valves, as well as load handling and manipulation, double-acting hydraulic cylinders are widely used in agricultural machinery for various tasks. Their versatility, power, and precise control make them essential components in modern agricultural equipment.

How does a double-acting hydraulic cylinder contribute to efficient force generation?

A double-acting hydraulic cylinder is designed to contribute to efficient force generation in hydraulic systems. Here’s a detailed explanation:

1. Bidirectional Force: A double-acting hydraulic cylinder is capable of generating force in both the extension and retraction strokes. When hydraulic fluid is applied to the cylinder’s cap end, it pushes the piston, creating a pushing force. Conversely, when hydraulic fluid is applied to the rod end, it pulls the piston, generating a pulling force. This bidirectional force capability allows for versatile and efficient force generation in various applications.

2. Mechanical Advantage: The design of a double-acting hydraulic cylinder provides a mechanical advantage that contributes to efficient force generation. The piston’s larger surface area on the cap end compared to the rod end allows for a greater force output during the extension stroke. This mechanical advantage amplifies the force generated by the hydraulic pressure, enabling the cylinder to exert significant pushing or pulling force with relatively low hydraulic pressure input.

3. Control over Force and Speed: Double-acting hydraulic cylinders offer precise control over the force and speed of the piston’s movement. By regulating the flow and pressure of the hydraulic fluid, the operator can adjust the force exerted by the cylinder to match the requirements of the application. This control allows for efficient force generation by optimizing the cylinder’s performance for specific tasks.

4. Efficient Energy Utilization: Double-acting cylinders are known for their efficient energy utilization. When the cylinder is extending or retracting, the opposite side of the piston can act as a reservoir, storing the hydraulic fluid. This stored energy can be utilized in the opposite stroke, resulting in improved efficiency. By recycling the energy within the system, double-acting cylinders maximize the utilization of input power, contributing to efficient force generation.

5. Compact and Space-Saving Design: Double-acting hydraulic cylinders are compact and space-saving, making them suitable for applications with limited space. Their efficient force generation allows for the use of smaller cylinder sizes without compromising performance. This compact design minimizes the footprint of the hydraulic system while still delivering the required force output, contributing to efficient use of available space.

6. Durability and Longevity: Double-acting hydraulic cylinders are built to withstand high-pressure applications and heavy loads. Their robust construction, often using materials such as steel or aluminum, ensures durability and longevity. By maintaining their performance over time without significant wear or failure, these cylinders contribute to efficient force generation throughout their operational lifespan.

In summary, a double-acting hydraulic cylinder contributes to efficient force generation through its bidirectional force capability, mechanical advantage, precise control over force and speed, efficient energy utilization, compact design, and durability. These features make double-acting cylinders highly effective in a wide range of applications where efficient and reliable force generation is crucial.

editor by CX 2024-04-02