Product Description

1 YEAR WARRANTY AND EXCELLENT SERVICE

7 DAYS REFUND PAYMENT IN CASE OF QUALITY

24 HOURS SMOOTHLY COMMUNICATION

Product Description

Hydraulic Cylinder Jack

Capacity: 50-800ton

Stroke: 50-300mm

Max.pressure: 700bar

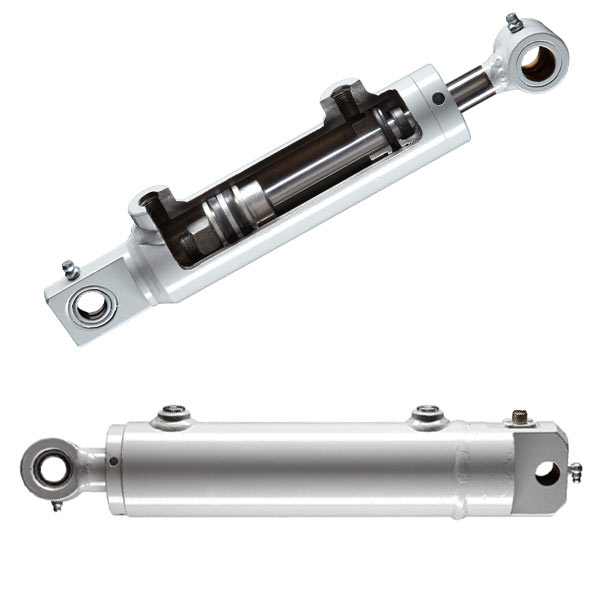

SJF Series Double-Acting High Tonnage Hydraulic Cylinders

1. Double acting,for positive retraction.

2. Hard chrome plated high quality steel plungers.

3. Plunger wiper reduces contamination,extending cylinder life.

4. The exclusive guide Ring is designed absorbs eccentric loading without galling cylinder parts,reduces wear and extending life.

5. Built-in safety valve prevents accidental over-pressurization.

6. Special painted surface to increase corrosion resistance.

7. Easy fixturing with base mounting holes.

8. All model include quick couplings (NPT3/8″-18) and dust-proof cap.

9. Removable hardened saddles protect plunger during lifting and pressing.

10. According to different work environment,special cylinder could be customized.

| Cylinder Capacity | Stroke | Model Number | Max.Cylinder Capacity | Cylinder Effective Area | Oil Capacity | Collapsed Height | Extended Height | Outside Dia. | Cylinder Bore Dia | Plunger Dia. | Base to Advance Port | Top to Return Port | Mounting Hole Dimensions | Weight | |||||

| Bolt Circle | Thread | Thread Depth | |||||||||||||||||

| Advance | Retract | Advance | Retract | Advance | Retract | A | B | C | D | E | F | G | O | P | W | ||||

| ton | (mm) | (KN) | (cm2) | (cm3) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (kg) | |||||

| 50 | 50 | SJF50-50 | 550 | 255 | 78.5 | 40 | 392 | 200 | 188 | 238 | 140 | 100 | 70 | 41 | 41 | 70 | 4-M16 | 13 | 21.5 |

| 100 | SJF50-100 | 550 | 255 | 78.5 | 40 | 784 | 400 | 238 | 338 | 140 | 100 | 70 | 41 | 41 | 70 | 4-M16 | 13 | 26 | |

| 150 | SJF50-150 | 550 | 255 | 78.5 | 40 | 1176 | 600 | 288 | 438 | 140 | 100 | 70 | 41 | 41 | 70 | 4-M16 | 13 | 31 | |

| 200 | SJF50-200 | 550 | 255 | 78.5 | 40 | 1568 | 800 | 338 | 538 | 140 | 100 | 70 | 41 | 41 | 70 | 4-M16 | 13 | 35 | |

| 300 | SJF50-300 | 550 | 255 | 78.5 | 40 | 2352 | 1200 | 438 | 738 | 140 | 100 | 70 | 41 | 41 | 70 | 4-M16 | 13 | 44 | |

| 100 | 50 | SJF100-50 | 1077 | 490 | 153.9 | 75.4 | 770 | 377 | 216 | 266 | 188 | 140 | 100 | 54 | 54 | 100 | 4-M20 | 16 | 42 |

| 100 | SJF100-100 | 1077 | 490 | 153.9 | 75.4 | 1540 | 754 | 266 | 366 | 188 | 140 | 100 | 54 | 54 | 100 | 4-M20 | 16 | 49 | |

| 150 | SJF100-150 | 1077 | 490 | 153.9 | 75.4 | 2310 | 1131 | 316 | 466 | 188 | 140 | 100 | 54 | 54 | 100 | 4-M20 | 16 | 56 | |

| 200 | SJF100-200 | 1077 | 490 | 153.9 | 75.4 | 3080 | 1508 | 366 | 566 | 188 | 140 | 100 | 54 | 54 | 100 | 4-M20 | 16 | 63 | |

| 300 | SJF100-300 | 1077 | 490 | 153.9 | 75.4 | 4620 | 2262 | 466 | 766 | 188 | 140 | 100 | 54 | 54 | 100 | 4-M20 | 16 | 70 | |

| 150 | 50 | SJF150-50 | 1588 | 797 | 226.9 | 113.8 | 1134 | 565 | 226 | 276 | 228 | 170 | 120 | 58 | 58 | 130 | 4-M20 | 16 | 66 |

| 100 | SJF150-100 | 1588 | 797 | 226.9 | 113.8 | 2269 | 1130 | 276 | 376 | 228 | 170 | 120 | 58 | 58 | 130 | 4-M20 | 16 | 78 | |

| 150 | SJF150-150 | 1588 | 797 | 226.9 | 113.8 | 3403 | 1696 | 326 | 476 | 228 | 170 | 120 | 58 | 58 | 130 | 4-M20 | 16 | 90 | |

| 200 | SJF150-200 | 1588 | 797 | 226.9 | 113.8 | 4538 | 2260 | 376 | 576 | 228 | 170 | 120 | 58 | 58 | 130 | 4-M20 | 16 | 102 | |

| 300 | SJF150-300 | 1588 | 797 | 226.9 | 113.8 | 6806 | 3390 | 476 | 776 | 228 | 170 | 120 | 58 | 58 | 130 | 4-M20 | 16 | 126 | |

| 200 | 100 | SJF200-100 | 2198 | 875 | 314 | 137.4 | 3141 | 1374 | 296 | 396 | 268 | 200 | 150 | 64 | 68 | 160 | 4-M24 | 24 | 109 |

| 150 | SJF200-150 | 2198 | 875 | 314 | 137.4 | 4712 | 2061 | 346 | 496 | 268 | 200 | 150 | 64 | 68 | 160 | 4-M24 | 24 | 121 | |

| 200 | SJF200-200 | 2198 | 875 | 314 | 137.4 | 6282 | 2748 | 396 | 596 | 268 | 200 | 150 | 64 | 68 | 160 | 4-M24 | 24 | 132 | |

| 300 | SJF200-300 | 2198 | 875 | 314 | 137.4 | 9423 | 4122 | 496 | 796 | 268 | 200 | 150 | 64 | 68 | 160 | 4-M24 | 24 | 155 | |

| 300 | 100 | SJF300-100 | 3434 | 1654 | 490.6 | 236.3 | 4906 | 2363 | 327 | 427 | 320 | 250 | 180 | 74 | 76 | 220 | 4-M24 | 24 | 180 |

| 200 | SJF300-200 | 3434 | 1654 | 490.6 | 236.3 | 9812 | 4726 | 427 | 627 | 320 | 250 | 180 | 74 | 76 | 220 | 4-M24 | 24 | 220 | |

| 300 | SJF300-300 | 3434 | 1654 | 490.6 | 236.3 | 14718 | 7089 | 527 | 827 | 320 | 250 | 180 | 74 | 76 | 220 | 4-M24 | 24 | 260 | |

| 400 | 100 | SJF400-100 | 4308 | 1649 | 615.4 | 235.5 | 6154 | 2355 | 355 | 455 | 370 | 280 | 210 | 83 | 83 | 240 | 4-M24 | 24 | 255 |

| 200 | SJF400-200 | 4308 | 1649 | 615.4 | 235.5 | 12308 | 4710 | 455 | 655 | 370 | 280 | 210 | 83 | 83 | 240 | 4-M24 | 24 | 310 | |

| 300 | SJF400-300 | 4308 | 1649 | 615.4 | 235.5 | 18462 | 7065 | 555 | 855 | 370 | 280 | 210 | 83 | 83 | 240 | 4-M24 | 24 | 375 | |

| 500 | 100 | SJF500-100 | 5114 | 1948 | 803.8 | 313.2 | 8038 | 3133 | 375 | 475 | 420 | 320 | 250 | 93 | 93 | 280 | 4-M24 | 24 | 326 |

| 200 | SJF500-200 | 5114 | 1948 | 803.8 | 313.2 | 16076 | 6266 | 475 | 675 | 420 | 320 | 250 | 93 | 93 | 280 | 4-M24 | 24 | 394 | |

| 300 | SJF500-300 | 5114 | 1948 | 803.8 | 313.2 | 24114 | 9399 | 575 | 875 | 420 | 320 | 250 | 93 | 93 | 280 | 4-M24 | 24 | 462 | |

| 600 | 100 | SJF600-100 | 6300 | 2488 | 1017.4 | 401.9 | 10174 | 4019 | 436 | 536 | 500 | 360 | 280 | 113 | 115 | 300 | 4-M24 | 24 | 542 |

| 200 | SJF600-200 | 6300 | 2488 | 1017.4 | 401.9 | 20348 | 8038 | 536 | 736 | 500 | 360 | 280 | 113 | 115 | 300 | 4-M24 | 24 | 634 | |

| 300 | SJF600-300 | 6300 | 2488 | 1017.4 | 401.9 | 30522 | 12057 | 636 | 936 | 500 | 360 | 280 | 113 | 115 | 300 | 4-M24 | 24 | 726 | |

| 800 | 100 | SJF800-100 | 8790 | 2880 | 1256 | 452.2 | 12566 | 4522 | 477 | 577 | 550 | 400 | 320 | 113 | 113 | 380 | 4-M24 | 24 | 796 |

| 200 | SJF800-200 | 8790 | 2880 | 1256 | 452.2 | 25132 | 9044 | 577 | 777 | 550 | 400 | 320 | 113 | 113 | 380 | 4-M24 | 24 | 944 | |

| 300 | SJF800-300 | 8790 | 2880 | 1256 | 452.2 | 37698 | 13566 | 677 | 977 | 550 | 400 | 320 | 113 | 113 | 380 | 4-M24 | 24 | 1092 | |

All SAIVS Hydraulic Lifting Cylinders Jack go with calibration certificates,

Your Requirements Can Be Customized, Please Contact Us Freely!

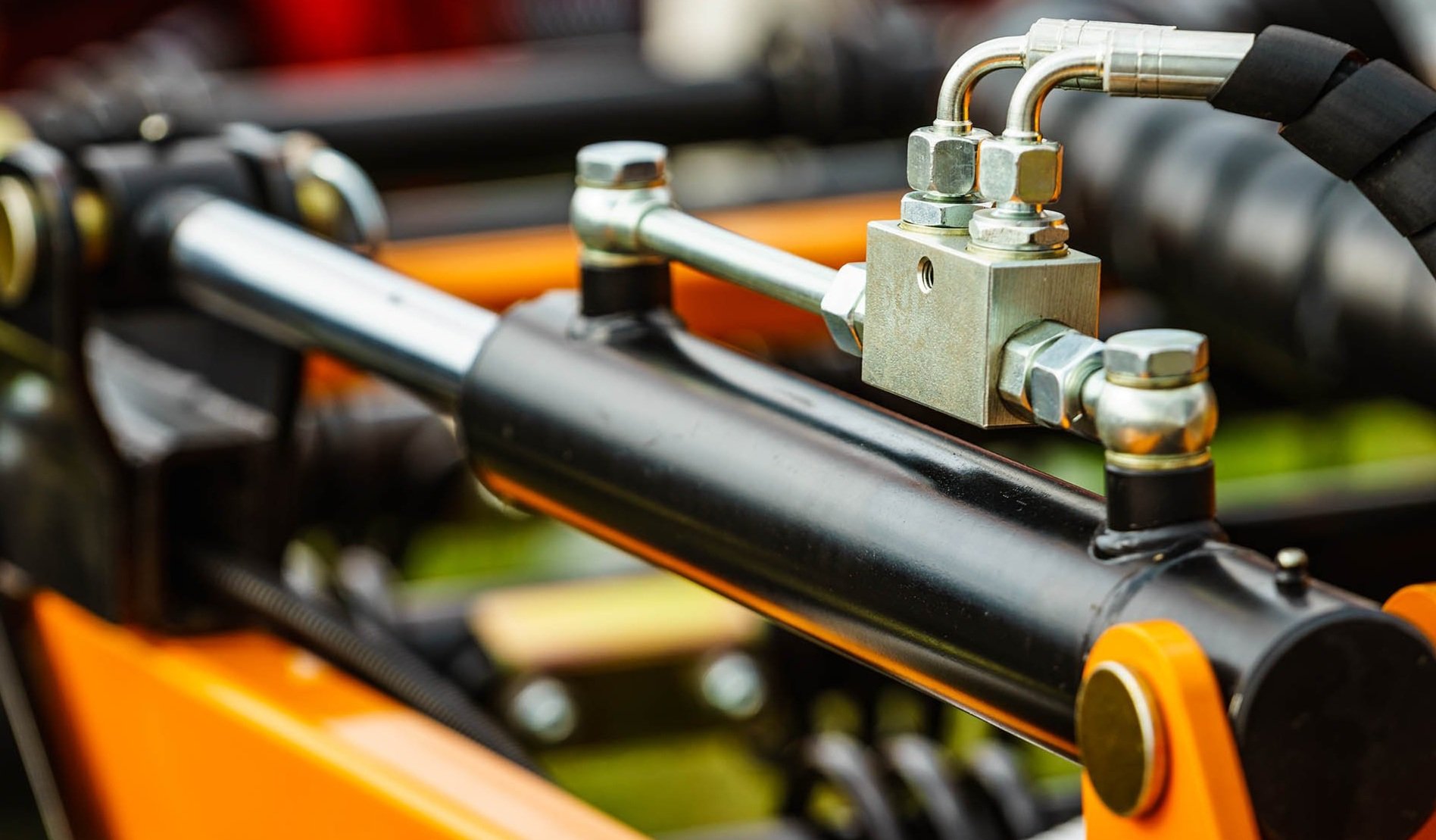

Detailed Photos

Double-Acting High Tonnage Hydraulic Cylinders

SAIVS is a professional manufacturer in hydraulic tools and products, Hydraulic lifting cylinder & jack and Hydraulic pumps.

Our full rang of popular hydraulic cylinder reserviors including jacking, pushing, pulling, supporting etc.

Our hydraulic products have been widely used in petrochemical, Building, shipbuilding, steel plant and heavy constructions areas etc.

Application

Certifications

Packaging & Shipping

Company Profile

Established in HangZhou, China, CHINAMFG began as a manufacturer and exporter of different kinds of casting and precision CNC machining components, industrial customized parts. CHINAMFG has the experience to develop thousands of tooling and fixtures in house according to customers’ drawings.

In 2002, hydraulic tools research department was settled and company developed its first line of hydraulic tools and equipment. Today CHINAMFG is reckoned as 1 of the most preferred experienced manufacturer and exporter of hydraulic tools, hydraulic pumps & hydraulic components in the industrial market.

We have more than 200 employees total, that work at casting foundries, CNC machining plant. we have nice reputation in components supply chain, as we have better management system, positive teamwork cooperation and advanced equipment. We obtained certificates of TS16949, ISO9001, ISO14001 and OSHAS ISO 18001.

FAQ

Q: Are you trading company or manufacturer?

A: We are factory with more than 20 years experience.

Q: How long for delivery?

A: Generally it is 15-30days as we are customized service we confirm with customer when place order.

Q: What is the MOQ?

A: It depends on what you are buying. Normally, our minimum order is 1 20′ full container and LCL container (less than a

container load) can be acceptable.

Q: Can you customize my products?

A: Yes, we can customized products with your design drawings like DWG, DXF, DXW, IGES, STEP, PDF etc.

Q: What is your terms of payment?

A: 30% T/T in advance, balance before shipment, or as per discussion.

Q: What about your quality control?

A: * . Checking the raw material after they reach our factory—–Incoming quality control(IQC)

* . Checking the details before the production line operated

* . Have full inspection and routing inspection during mass production—-In-process quality control(IPQC)

* . Checking the goods after they are finished—-Final quality control(FQC)

* . Checking the goods after they are finished—-Outgoing quality control(QC)

* . 100% inspection and delivery before shipment

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Yes |

|---|---|

| Warranty: | 1 Year |

| Type: | Hydraulic Jack |

| Structure: | Hydraulic Jack |

| Capacity (Load): | 50-800 T |

| Power Source: | Hydraulic |

| Customization: |

Available

|

|

|---|

Can double-acting hydraulic cylinders be used in construction equipment like backhoes?

Yes, double-acting hydraulic cylinders are commonly used in construction equipment like backhoes. Here’s a detailed explanation:

1. Lifting and Digging Functions: Backhoes are versatile construction machines used for various tasks, including digging, trenching, lifting, and material handling. Double-acting hydraulic cylinders play a crucial role in enabling the lifting and digging functions of a backhoe. These cylinders are typically used to control the movement of the boom, dipper stick, and bucket assembly. By extending and retracting the hydraulic cylinders, the boom can be raised, lowered, and positioned precisely, allowing for efficient digging and material handling operations.

2. Bi-Directional Force Generation: Double-acting hydraulic cylinders are well-suited for the requirements of backhoes due to their ability to generate force in both directions. This bi-directional operation is essential for the backhoe’s lifting and digging functions. By supplying pressurized hydraulic fluid to one side of the cylinder, the piston extends, producing force that raises or extends the boom. Conversely, supplying fluid to the other side of the cylinder retracts the piston, allowing for the lowering or retraction of the boom. This bi-directional force generation enables precise control over the movement and positioning of the backhoe’s working components.

3. Precise Control and Positioning: Backhoes often require precise control and positioning of the boom, dipper stick, and bucket assembly. Double-acting hydraulic cylinders contribute to this precise control by allowing operators to adjust the speed and force of the cylinder’s movement. By regulating the hydraulic pressure and flow rate, the operator can control the speed and smoothness of the cylinder’s extension and retraction. This level of control enables accurate and controlled movement, facilitating precise digging, lifting, and material handling tasks.

4. Adaptability and Customization: Double-acting hydraulic cylinders can be customized to meet the specific requirements of backhoes and other construction equipment. They can be designed with various stroke lengths, bore sizes, and mounting configurations to fit the backhoe’s hydraulic system and geometry. This adaptability ensures that the hydraulic cylinders integrate seamlessly with the backhoe’s structure and hydraulic circuit, optimizing performance and efficiency.

5. Durability and Reliability: Construction equipment like backhoes operate in demanding and often harsh conditions. Double-acting hydraulic cylinders are built to withstand these challenging environments. They are constructed from robust materials, such as high-strength steel, and equipped with reliable sealing mechanisms to prevent the ingress of contaminants. This ensures the durability and reliability of the hydraulic cylinders, allowing them to withstand the rigors of construction sites and provide consistent performance over time.

Given their suitability for lifting and digging functions, bi-directional force generation, precise control and positioning, adaptability and customization, as well as durability and reliability, double-acting hydraulic cylinders are extensively used in construction equipment like backhoes.

Can double-acting hydraulic cylinders be used in automotive repair and maintenance?

Yes, double-acting hydraulic cylinders can be extensively used in automotive repair and maintenance. Here’s a detailed explanation:

1. Lifting and Lowering Vehicles: Double-acting hydraulic cylinders are commonly employed in automotive lifts and jacks for lifting and lowering vehicles. These cylinders provide the necessary force to raise vehicles off the ground, allowing mechanics to access the underside of the vehicle for repairs, maintenance, or inspections. The bidirectional force generation of double-acting cylinders enables precise control over the lifting and lowering process, ensuring the safety and stability of the vehicle during automotive tasks.

2. Pressing and Clamping: Automotive repair often involves pressing or clamping components together during assembly or disassembly processes. Double-acting hydraulic cylinders can be used in hydraulic presses or clamping devices to provide the required force. By supplying hydraulic pressure to one side of the cylinder, the piston extends, applying force to press or clamp components together. By supplying pressure to the other side, the piston retracts, releasing the pressure. This capability allows for precise and controlled pressing or clamping operations in automotive repair and maintenance.

3. Brake and Suspension System Maintenance: Double-acting hydraulic cylinders play a vital role in brake and suspension system maintenance. For example, when bleeding brake lines, a hydraulic cylinder can be used to pressurize the brake system and force the air bubbles out of the brake fluid. Similarly, in suspension system maintenance, hydraulic cylinders can be employed to compress or decompress suspension components, facilitating repairs or replacements. The precise force control offered by double-acting cylinders ensures accurate and effective maintenance of these critical automotive systems.

4. Engine Hoists and Tilters: Engine repair and maintenance often require lifting, tilting, or removing heavy engines from vehicles. Double-acting hydraulic cylinders are utilized in engine hoists and tilters to provide the necessary force for these tasks. The cylinders can be integrated into lifting mechanisms, allowing controlled lifting and tilting of engines for access to various components or for engine removal and installation. The precise force application of double-acting cylinders ensures the safe handling of heavy engine assemblies.

5. Wheel Alignment and Balancing: Double-acting hydraulic cylinders are also used in wheel alignment and balancing equipment. These cylinders provide the force required to adjust wheel angles and balance tires accurately. By applying precise force to the wheel clamps or alignment mechanisms, the cylinders enable mechanics to align wheels correctly and achieve balanced tire rotations, ensuring optimal vehicle performance, safety, and tire longevity.

Given their applications in lifting and lowering vehicles, pressing and clamping operations, brake and suspension system maintenance, engine hoisting and tilting, as well as wheel alignment and balancing, double-acting hydraulic cylinders are indispensable in automotive repair and maintenance. Their precise force control and versatility make them valuable tools for mechanics and technicians in the automotive industry.

How does a double-acting hydraulic cylinder differ from a single-acting one?

A double-acting hydraulic cylinder and a single-acting hydraulic cylinder differ in their functionality and ability to generate force. Here’s a detailed explanation of the differences:

1. Functionality: A double-acting hydraulic cylinder can generate force in both directions of its stroke, whereas a single-acting hydraulic cylinder can only generate force in one direction.

2. Construction: In a double-acting hydraulic cylinder, there are two hydraulic ports—one connected to the rod end and the other to the cap end of the cylinder. This allows hydraulic fluid to enter and exit both chambers of the cylinder, enabling force generation in both directions. In contrast, a single-acting hydraulic cylinder has only one hydraulic port, typically connected to the cap end. The rod end of a single-acting cylinder is often vented or equipped with a smaller hydraulic port to facilitate the return of the piston.

3. Operation: A double-acting hydraulic cylinder operates by supplying hydraulic fluid to the appropriate ports to extend or retract the piston. By controlling the flow and pressure of the hydraulic fluid, operators can regulate the direction and speed of the piston’s movement, generating pushing and pulling forces. In a single-acting hydraulic cylinder, hydraulic fluid is supplied to the port to extend the piston and generate force in one direction. The return stroke of the piston is accomplished by the force of gravity or an external mechanical load, as there is no hydraulic pressure applied to retract the piston.

4. Applications: Due to their ability to generate force in both directions, double-acting hydraulic cylinders are suitable for applications that require bidirectional force, precise control, and versatility. They are commonly used in tasks such as lifting, pushing, pulling, clamping, and more. Single-acting hydraulic cylinders, on the other hand, are often employed in applications where force is required in only one direction, such as in simple lifting or lowering tasks.

5. Efficiency: Double-acting hydraulic cylinders offer improved efficiency compared to single-acting cylinders in applications that require frequent or continuous bidirectional force. With a double-acting cylinder, the force can be applied in both the extension and retraction strokes, allowing for increased productivity and reduced cycle times.

In summary, the main difference between a double-acting hydraulic cylinder and a single-acting hydraulic cylinder lies in their ability to generate force in one or both directions. While a double-acting cylinder can generate force in both directions, a single-acting cylinder can generate force in only one direction. This distinction impacts their construction, operation, applications, and efficiency in various hydraulic systems.

editor by CX 2024-03-21