Product Description

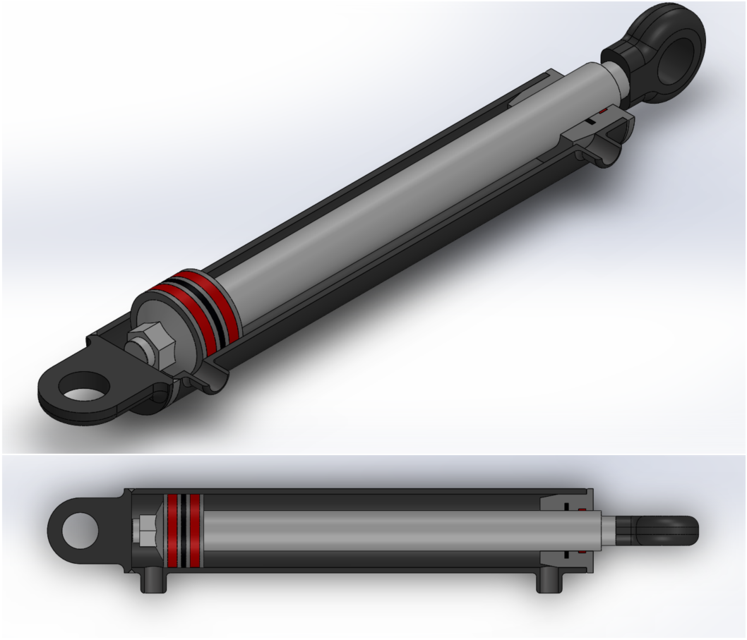

GYX series high performance mini hydraulic cylinder

Bore size mm, YGX mini hydraulic cylinder double acting, JIS structures interchangeable, China factory, Max pressure 7MPa, Pressure resistance 10.5MPa, Minimum starting pressure 0.3MPa, working temperature -10-80ºC

please contact sales engineer, we will fast feedback and support your needs.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | -10~80c |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Structure: | Piston Type |

| Samples: |

US$ 65/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can double-acting hydraulic cylinders be applied in both mobile and stationary machinery?

Yes, double-acting hydraulic cylinders can be applied in both mobile and stationary machinery. Here’s a detailed explanation:

1. Mobile Machinery: Double-acting hydraulic cylinders find extensive use in various types of mobile machinery. These include construction equipment such as excavators, loaders, and bulldozers, where hydraulic cylinders are utilized for tasks like lifting, digging, and pushing. Agricultural machinery such as tractors, harvesters, and sprayers also employ hydraulic cylinders for functions like raising and lowering attachments, steering, and operating implements. Additionally, hydraulic cylinders are employed in material handling equipment, such as forklifts and cranes, for lifting, lowering, and moving heavy loads. The ability of double-acting hydraulic cylinders to generate bi-directional force and provide precise control makes them well-suited for the dynamic and versatile requirements of mobile machinery.

2. Stationary Machinery: Double-acting hydraulic cylinders are equally applicable in stationary machinery across various industries. In industrial manufacturing, hydraulic cylinders are used in presses, machine tools, and assembly equipment for tasks like clamping, pressing, and forming. They are also employed in the mining and quarrying industry for equipment such as rock crushers and conveyors, providing force for crushing, conveying, and material handling operations. Stationary hydraulic lifts and platforms, such as scissor lifts or dock levelers, rely on hydraulic cylinders for vertical movement and positioning. The versatility and controllability of double-acting hydraulic cylinders make them suitable for precise and reliable operation in stationary machinery.

3. Adaptability: Double-acting hydraulic cylinders offer adaptability that allows them to be applied in both mobile and stationary machinery. They can be designed and manufactured to meet specific requirements, such as different stroke lengths, bore sizes, and mounting configurations, ensuring compatibility with a wide range of applications. Hydraulic systems, including double-acting cylinders, can also be integrated into both mobile and stationary machinery designs, providing a common and standardized power transmission solution. This adaptability enables the use of double-acting hydraulic cylinders in diverse machinery across various industries.

4. Maintenance and Service: Double-acting hydraulic cylinders can be maintained and serviced in both mobile and stationary machinery. Regular maintenance activities such as seal replacement, fluid checks, and lubrication can be performed to ensure optimal performance and longevity. In the case of repairs or component replacements, hydraulic cylinders can be disassembled, repaired, or replaced as needed, regardless of whether they are installed in mobile or stationary machinery.

Given their versatility, adaptability, and maintenance capabilities, double-acting hydraulic cylinders are widely employed in both mobile and stationary machinery, meeting the demanding requirements of diverse industries.

How does a double-acting hydraulic cylinder handle variations in cylinder stroke and extension?

A double-acting hydraulic cylinder is designed to handle variations in cylinder stroke and extension effectively. Here’s a detailed explanation:

1. Bidirectional Operation: One of the key advantages of a double-acting hydraulic cylinder is its ability to generate force in both the extending and retracting strokes. This bidirectional operation allows the cylinder to handle variations in stroke and extension. Whether the cylinder needs to extend or retract, hydraulic fluid can be supplied to the appropriate side of the cylinder, enabling the desired movement. This flexibility in operation allows for easy adjustment to accommodate different stroke lengths and extension requirements.

2. Adjustable Stroke Length: Double-acting hydraulic cylinders often feature adjustable stroke lengths. The stroke length refers to the distance the piston can travel within the cylinder. By adjusting the position of the end stops or limit switches, the stroke length of the cylinder can be modified to match specific application requirements. This adjustability enables the cylinder to handle variations in stroke length and extension, allowing for precise positioning and the accommodation of different workpiece sizes or operational needs.

3. Control of Hydraulic Fluid Flow: The flow rate and pressure of the hydraulic fluid can be controlled to manage variations in cylinder stroke and extension. By adjusting the flow control valves and regulating the hydraulic pressure, operators can achieve the desired speed and force during cylinder operation. This control over fluid flow allows for smooth and controlled movement, compensating for any variations in stroke length or extension requirements.

4. Position Sensing and Feedback: Double-acting hydraulic cylinders often incorporate position sensing devices or feedback mechanisms. These sensors can detect the position of the piston within the cylinder and provide feedback to the control system. By monitoring the position feedback, operators can ensure accurate and consistent stroke lengths and extensions. This feedback loop helps to maintain precise control over the cylinder’s movement, compensating for any variations and ensuring reliable performance.

5. Robust Construction and Tolerance Compensation: Double-acting hydraulic cylinders are built with robust construction and designed to handle variations in stroke and extension. They are typically manufactured with close tolerances to minimize internal leakage and ensure efficient operation. Additionally, the seals and piston rings used in the cylinder are designed to accommodate minor variations and provide a reliable and consistent seal, compensating for any tolerance differences and maintaining the integrity of the hydraulic system.

Through bidirectional operation, adjustable stroke length, control of hydraulic fluid flow, position sensing and feedback, as well as robust construction and tolerance compensation, double-acting hydraulic cylinders effectively handle variations in cylinder stroke and extension. These features make them versatile and adaptable components in various industries, including manufacturing, construction, and automation.

What is a double-acting hydraulic cylinder and how does it function?

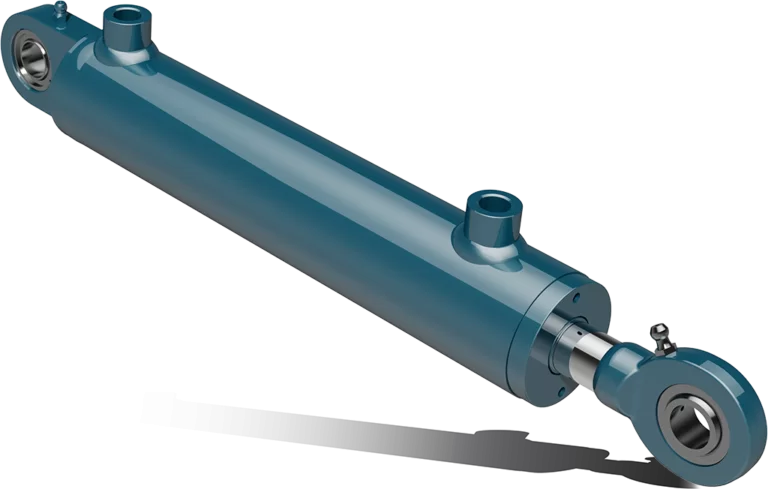

A double-acting hydraulic cylinder is a type of hydraulic cylinder that can generate force in both directions of its stroke. Here’s a detailed explanation of its function:

1. Design and Construction: A double-acting hydraulic cylinder consists of a cylindrical barrel, a piston, and two hydraulic ports. The barrel is sealed at both ends, and the piston divides the interior of the cylinder into two chambers. The hydraulic ports are connected to a hydraulic system, allowing the flow of hydraulic fluid into and out of the cylinder.

2. Functionality: The double-acting hydraulic cylinder operates using hydraulic pressure to extend and retract the piston, generating force in both directions. Here’s how it functions:

– Extension Stroke: When hydraulic fluid is supplied to the port connected to the rod end of the cylinder, it enters the cylinder’s rod-end chamber. The pressure of the hydraulic fluid pushes against the piston, causing it to move away from the rod end and extend the cylinder’s rod. This extension stroke generates a pushing force at the rod end of the cylinder.

– Retraction Stroke: Conversely, when hydraulic fluid is supplied to the port connected to the cap end of the cylinder, it enters the cylinder’s cap-end chamber. The pressure of the hydraulic fluid pushes against the piston from the opposite direction, causing it to move towards the rod end and retract the cylinder’s rod. This retraction stroke generates a pulling force at the rod end of the cylinder.

3. Sealing Mechanism: To ensure efficient operation, double-acting hydraulic cylinders incorporate sealing mechanisms. These seals prevent hydraulic fluid leakage between the piston and the cylinder barrel, maintaining the separation of the two chambers.

4. Control and Application: The operation of double-acting hydraulic cylinders is controlled by the hydraulic system supplying and retracting hydraulic fluid. By controlling the flow and pressure of the hydraulic fluid, operators can regulate the extension and retraction speeds and precisely control the force generated by the cylinder. Double-acting hydraulic cylinders find applications in various industries, including manufacturing, construction, mining, agriculture, and more, where controlled linear force is required for tasks such as lifting, pushing, pulling, and clamping.

In summary, a double-acting hydraulic cylinder is a hydraulic component capable of generating force in both directions of its stroke. By supplying hydraulic fluid to the appropriate ports, the cylinder extends or retracts its piston, creating pushing or pulling forces. The sealing mechanism ensures efficient operation, and the control of hydraulic fluid flow allows for precise force control. Double-acting hydraulic cylinders are widely used in diverse industries for a range of applications that require controlled linear force.

editor by CX 2024-01-02