Product Description

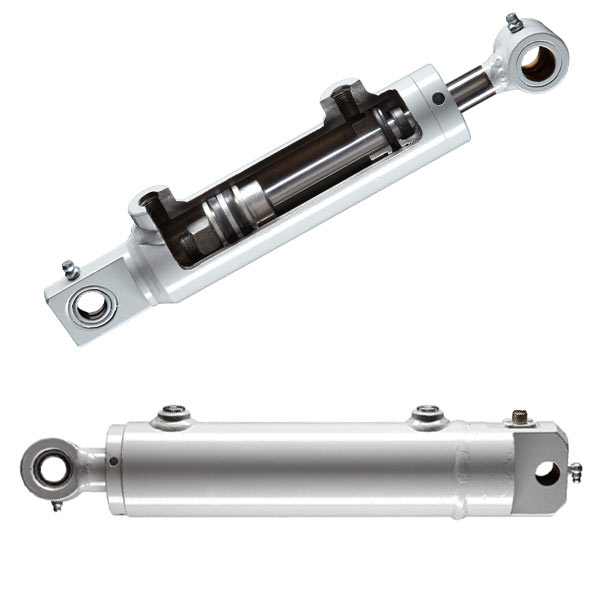

HYDRAULIC CYLINDER

Widely used in equipment for Construction, Coal&mine, Agriculture , Aerial work table and Environmental sanitation etc.

| Features | customized hydraulic cylinder |

| Bore Diameter | 2′-50’/50-1500mm |

| Rod Diameter | 1′ – 60’/25 -1000 mm |

| Wall Thickness | 0.1′-4’/3-100 mm |

| Max Stroke | 366’/9280 mm |

| Max Pressure | 9600 psi/600 bar |

| Test Pressure | 14500 psi/1000 bar |

| Material | 20#,40#,45#,16Mn,27SiMn,etc |

| Seal Kits | Hallite, Parker, NOK, SKF, DICHTOMATIK, Trelleborg, Merkel |

| Dimensional Accuracy | H7-H11 |

| Bore Roughness | Ra 0.4-1.6mm |

| Coating | hard chrome |

| Purpose | engineering, Coal &mining, agricultural machinery, environmental sanitation |

| OEM/ODM | Yes |

| MOQ | 1 Piece |

| Certificates | ISO9001,CE, CCS |

Q1. Are you a manufacturer?

Yes, we have manufactured hydraulic cylinders for over 30 years. They are widely used in Engineers, Coal&mine, Agriculture and Environmental Sanitation etc.

Q2. Do your products come with a warranty?

Yes, we have 1 year warranty.

Q3. Can we customize our products from you?

Yes, actually 70% of our products are customized for our clients. You just need to let us know your demand (specifications &drawing is better), and we shall realize them for you.

Q4. How do you deliver the products?

By sea, by plane, or by couriers.

Q5. How many days the samples can be finished, And how about the mass production?

Generally 5-7days for samples making. The lead time of mass production will depend on quality, production art and so on. Generally 35days.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Structure: | Piston Type |

| Material: | Carbon Steel |

| Customization: |

Available

|

|

|---|

How does a double-acting hydraulic cylinder contribute to energy-efficient force generation?

A double-acting hydraulic cylinder plays a significant role in energy-efficient force generation. Here’s a detailed explanation:

1. Bi-Directional Operation: One of the key features of a double-acting hydraulic cylinder is its ability to generate force in both directions. This bi-directional operation allows for efficient energy utilization. When pressurized hydraulic fluid is supplied to one side of the cylinder, the piston extends, generating force in one direction. Conversely, when the fluid is supplied to the other side, the piston retracts, producing force in the opposite direction. By utilizing both extension and retraction strokes, the hydraulic cylinder maximizes force output while minimizing energy consumption.

2. Conservation of Potential Energy: A double-acting hydraulic cylinder has the ability to conserve and utilize potential energy effectively. During the extension stroke, the cylinder stores potential energy in the compressed hydraulic fluid. This stored energy can be released during the retraction stroke, minimizing the need for additional energy input. By harnessing and reusing this potential energy, the hydraulic cylinder contributes to energy efficiency, reducing the overall energy requirements for force generation.

3. Load Counterbalancing: In certain applications, a double-acting hydraulic cylinder can be used for load counterbalancing, further enhancing energy efficiency. Load counterbalancing involves using the hydraulic cylinder to oppose and balance external loads, reducing the overall energy required to move or hold the load. By strategically applying hydraulic pressure to the appropriate side of the cylinder, the system can counterbalance the load’s weight, minimizing energy consumption and improving efficiency.

4. Flow Control and Regeneration: Double-acting hydraulic cylinders can incorporate flow control and regeneration mechanisms to optimize energy efficiency. Flow control valves can be used to regulate the flow rate of hydraulic fluid, ensuring that the force generation matches the required load and speed. Regeneration valves or circuits allow the hydraulic fluid to be redirected during the cylinder’s retraction stroke, bypassing the pump and reducing energy consumption. These control and regeneration features enable the hydraulic system to operate with improved energy efficiency, minimizing waste and maximizing force generation per unit of energy input.

5. System Integration and Optimization: Energy-efficient force generation with a double-acting hydraulic cylinder is not limited to the cylinder alone but involves the integration and optimization of the entire hydraulic system. By designing the hydraulic system with the appropriate components, such as efficient pumps, valves, and control systems, the overall system efficiency can be improved. Proper system sizing, pressure control, and fluid management contribute to minimizing energy losses and maximizing the energy efficiency of force generation.

By leveraging bi-directional operation, conserving potential energy, load counterbalancing, flow control and regeneration, as well as system integration and optimization, a double-acting hydraulic cylinder significantly contributes to energy-efficient force generation. These features make hydraulic systems with double-acting cylinders suitable for applications where energy efficiency is a priority, such as in industrial machinery, construction equipment, and mobile hydraulic systems.

Can double-acting hydraulic cylinders be applied in mining equipment for material transport?

Yes, double-acting hydraulic cylinders are widely used in mining equipment for material transport. Here’s a detailed explanation:

1. Dump Trucks: Dump trucks are commonly used in mining operations for transporting large quantities of material, such as rocks, ores, and coal. Double-acting hydraulic cylinders are employed in the tipping mechanism of dump trucks. These cylinders provide the necessary force to raise the truck bed, allowing the material to be unloaded at the desired location. The bidirectional force generation of double-acting cylinders enables controlled and efficient tipping of the truck bed, facilitating the rapid and effective transport of materials.

2. Front Shovels and Excavators: Front shovels and excavators are heavy-duty machines used in mining for digging and loading materials onto trucks or conveyor systems. Double-acting hydraulic cylinders are utilized in the boom and bucket mechanisms of these machines. The cylinders provide the force required to extend and retract the boom, as well as to control the bucket’s opening and closing. This allows operators to manipulate the excavator effectively, scoop up materials, and deposit them into transport vehicles or processing equipment.

3. Conveyor Systems: Conveyor systems are extensively used in mining operations to transport bulk materials over long distances. Double-acting hydraulic cylinders are employed in conveyor belt tensioning systems. These cylinders apply force to adjust the tension of the conveyor belt, ensuring proper alignment and preventing slippage. The precise force control offered by double-acting cylinders allows for accurate tension adjustment, optimizing the efficiency and reliability of material transport on the conveyor system.

4. Haulage Systems: Haulage systems, such as underground mine trucks and railcars, are crucial for transporting materials within mining operations. Double-acting hydraulic cylinders are employed in these systems for various functions. For instance, the cylinders can be used to control the opening and closing of doors or gates on mine trucks or railcars, facilitating the loading and unloading of materials. Additionally, hydraulic cylinders can be utilized in braking systems to provide the necessary force for safe and controlled stopping of the haulage vehicles.

5. Lifting and Positioning Equipment: In mining operations, lifting and positioning equipment, such as cranes and hoists, are employed to handle heavy materials and equipment. Double-acting hydraulic cylinders play a vital role in these machines. The cylinders provide the force necessary for lifting, lowering, and positioning loads with precision. Whether it’s lifting large mining equipment or positioning heavy materials, hydraulic cylinders ensure safe and controlled movement, enhancing the efficiency of material transport in mining operations.

Given their applications in dump trucks, front shovels and excavators, conveyor systems, haulage systems, as well as lifting and positioning equipment, double-acting hydraulic cylinders are widely applied in mining equipment for material transport. Their ability to generate precise and controllable forces makes them essential components in ensuring efficient and reliable material handling in the mining industry.

How does a double-acting hydraulic cylinder handle variations in hydraulic pressure?

A double-acting hydraulic cylinder is designed to handle variations in hydraulic pressure while maintaining its functionality and performance. Here’s a detailed explanation:

1. Balanced Design: Double-acting hydraulic cylinders are designed with a balanced piston and rod arrangement. This design ensures that the hydraulic pressure acts equally on both sides of the piston, allowing for consistent and balanced force generation. As a result, the cylinder can handle variations in hydraulic pressure without compromising its ability to extend and retract smoothly.

2. Efficient Sealing System: Double-acting cylinders incorporate a sealing system that helps maintain the integrity of the hydraulic fluid and prevents leakage. The piston and rod seals, typically made of materials like rubber or polyurethane, create a tight seal between the piston and the cylinder barrel. This sealing system ensures that hydraulic pressure is effectively contained within the cylinder, reducing the impact of pressure variations on the cylinder’s performance.

3. Pressure Relief Mechanism: In situations where there are significant variations in hydraulic pressure, double-acting hydraulic cylinders may incorporate a pressure relief mechanism. This mechanism allows excess pressure to be released from the cylinder, preventing damage to the seals and other internal components. Pressure relief valves or adjustable relief valves are commonly used to regulate the pressure within the cylinder and protect it from excessive pressure fluctuations.

4. Robust Construction: Double-acting hydraulic cylinders are constructed using high-strength materials such as steel or aluminum. This robust construction enables the cylinder to withstand variations in hydraulic pressure without deformations or failures. The materials used, along with proper engineering and manufacturing techniques, ensure the structural integrity of the cylinder even under challenging pressure conditions.

5. Performance Testing and Quality Control: Manufacturers of double-acting hydraulic cylinders subject their products to rigorous performance testing and quality control measures. These tests evaluate the cylinder’s ability to handle variations in hydraulic pressure, ensuring that it meets the required performance and safety standards. Through these quality control processes, any potential issues related to pressure variations are identified and addressed before the cylinder is deployed.

By employing a balanced design, efficient sealing system, pressure relief mechanisms, robust construction, and thorough quality control, double-acting hydraulic cylinders can effectively handle variations in hydraulic pressure. These features ensure the cylinder’s reliability, longevity, and consistent performance in diverse hydraulic systems and applications.

editor by CX 2023-12-25