Product Description

Model

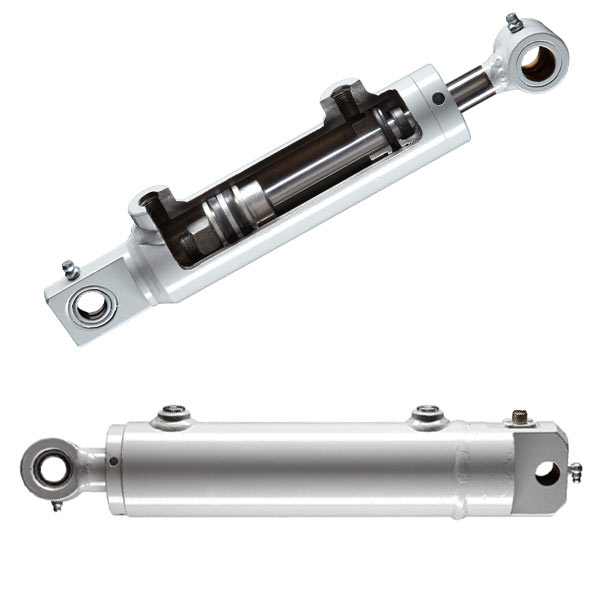

CHINAMFG series – Front end cylinder with double eye

FEE A110-3-57110-223-K1075

Item no.: 7571110

Product introduce

The FEE pin-to-pin cylinder is the most common telescopic in North America. These range with first stage diameters from 4.3″ to 9″, with strokes up to 336″, and working pressures up to 3626 psi. The standard 2″ spherical bearing for the top eye helps against side loads, and hard chromed pistons keep the cylinders life extended.

| Working temperature | -40°C ~ 80°C |

| Max. duration of extension | 0.5 hour |

| Color | RAL9005,Customize |

| Material | CK45,ST52,ST52-3,27SiMn,Customize |

| Seal kit | Trelleborg, Halite, Chesterton, NOK, Kayaba |

| Piston rod | Hard chromed |

| Packaging | Plywood case |

| Warranty | 12 months |

| Payment | T/T |

Specification

| Max. Working pressure | 250bar |

| Weight | 74kg |

| Working volume | 14L |

| Total volume | 16L |

| Max. Cyl. Load (start tipping) | 195kN |

| Extension | 1 | 2 | 3 |

| Diameter | 110mm | 91mm | 72mm |

| stroke | 690mm | 710mm | 710mm |

Pictures

Company introduction

HangZhou CHINAMFG is a comprehensive manufacturing enterprise engaged in hydraulic cylinders, excavator attachment, metal casting, hydraulic components with certification approval to meet custom or OEM requirements.

ROCA owned factory offers customers effective-cost products with quality assurance. With its professional and experienced R&D team, CHINAMFG Hydraulic devotes itself to research and development to optimize products applied in construction, mining, waste management, forestry, agriculture, etc.

Hydraulic cylinders are the most effective and efficient method of pushing, pulling, lifting, and lowering.

Nowadays hydraulic cylinders play an essential role in daily application and industry:

√ Mining

√ Earthmoving & Construction

√ Agriculture &Forestry

√Waste Management & Material Handing

√Ship crane & offshore

Selecting the right cylinders for an application is critical in obtaining maximum performance and reliability.

CHINAMFG team takes all your concerns into consideration to suit your hydraulic cylinder requirements.

Together, we work out the best design solution for your application.

FAQ

Q1.Do you have MOQ?

Depending on different ideas, Can be negotiated. The larger the quantity is, the competitive the unit price will be.

Q2.Should the customer pay the delivery fee, How much is it?

For the delivery fee, many samples are being requested to be sent, so we must get the delivery fee.

If you tell me to use the appointed Express, you will give me your express account or you will pay according to the Express.

If you do not request, I will choose a cheap one in China.

Q3.How about the after sale service?

1) We will always keep the quality the same as the buyer’s samples and if there is something with the quality, we will make compensation for our customers.

2) We will suggest our packing and take charge in our packing, we will keep the goods safe in the delivery.

3) We will trace the goods from the production to selling, we will solve the problems in the selling for our customers.

Q4.When can I get a price?

We usually quote within 24 hours after we get your inquiry.

Q5: Are you a trade company or manufacturer?

We are a professional manufacturer with our own factory.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Normal Temperature |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does a double-acting hydraulic cylinder contribute to controlled and precise movement?

A double-acting hydraulic cylinder plays a crucial role in achieving controlled and precise movement in hydraulic systems. Here’s a detailed explanation:

1. Bi-Directional Operation: Double-acting hydraulic cylinders are designed to generate force in both directions. By supplying pressurized hydraulic fluid to the cap end of the cylinder, the piston extends and produces force. Conversely, supplying fluid to the rod end retracts the piston. This bi-directional operation allows for precise control over the movement of loads in both directions, enabling controlled and precise positioning.

2. Adjustable Force Output: The force output of a double-acting hydraulic cylinder can be adjusted by controlling the hydraulic pressure applied to the cylinder. By regulating the pressure in the hydraulic system, the force generated by the cylinder can be varied to match the specific load requirements. This adjustability allows for precise control over the force exerted by the cylinder, contributing to controlled and precise movement.

3. Flow Control: Double-acting hydraulic cylinders can incorporate flow control valves or throttle valves in the hydraulic circuit. These valves regulate the flow rate of hydraulic fluid entering or exiting the cylinder, controlling the speed of movement. By adjusting the flow rate, the movement of the cylinder can be slowed down or sped up, allowing for precise control over the speed of operation. This flow control capability enhances the controlled and precise movement of the cylinder.

4. Position Feedback Devices: To achieve precise movement, double-acting hydraulic cylinders can be equipped with position feedback devices, such as linear transducers or potentiometers. These devices provide real-time information about the position of the cylinder’s piston. The position feedback data can be used to accurately control the movement and position of the load, ensuring precise positioning and movement control.

5. Proportional Control: Double-acting hydraulic cylinders can be integrated into proportional control systems. Proportional control utilizes electronic or electro-hydraulic systems to proportionally regulate the hydraulic pressure and flow, allowing for fine control over the cylinder’s movement. This precise control mechanism enables accurate and controlled movement, making it suitable for applications that require precise positioning or synchronization of multiple cylinders.

6. System Stability: Double-acting hydraulic cylinders contribute to controlled and precise movement by providing system stability. The hydraulic fluid acts as an incompressible medium, transmitting force from the cylinder to the load without significant loss or deformation. This stability ensures that the movement of the cylinder is consistent and predictable, allowing for precise control over the load’s position.

7. Mechanical Advantage: Double-acting hydraulic cylinders leverage mechanical advantage to enhance controlled and precise movement. The design of the cylinder incorporates a larger surface area on the cap end of the piston compared to the rod end. This size difference creates a force amplification effect, enabling the cylinder to exert greater force during the extension stroke. This mechanical advantage allows for finer control over the movement and positioning of the load.

By combining bi-directional operation, adjustable force output, flow control, position feedback devices, proportional control, system stability, and mechanical advantage, double-acting hydraulic cylinders contribute to controlled and precise movement in a wide range of applications.

Can double-acting hydraulic cylinders be integrated into manufacturing machinery for pressing and clamping?

Yes, double-acting hydraulic cylinders are commonly integrated into manufacturing machinery for pressing and clamping operations. Here’s a detailed explanation:

1. Pressing Operations: Double-acting hydraulic cylinders are widely used in manufacturing machinery for pressing applications. These cylinders provide the necessary force to press objects together, such as joining components or shaping materials. Hydraulic presses equipped with double-acting cylinders can generate high forces consistently and precisely. The bidirectional force generation of double-acting cylinders allows for controlled pressing in both the extending and retracting strokes, making them suitable for a wide range of pressing tasks in industries such as automotive, aerospace, and metal fabrication.

2. Clamping Operations: Double-acting hydraulic cylinders are also well-suited for clamping operations in manufacturing machinery. Clamping involves holding objects securely in place during various processes, such as machining, welding, or assembly. Hydraulic clamps utilizing double-acting cylinders provide reliable and strong clamping force. The ability to generate force in both directions allows for secure clamping during both the clamping and unclamping phases. This ensures the stability and safety of workpieces during manufacturing operations, preventing movement or misalignment.

3. Force and Stroke Control: Double-acting hydraulic cylinders offer precise control over force and stroke, enhancing their effectiveness in pressing and clamping applications. The flow rate and pressure of the hydraulic fluid can be adjusted using valves and control mechanisms, allowing operators to regulate the force applied by the cylinder. Additionally, the stroke length of the cylinder can be controlled, enabling precise positioning and adjustment to accommodate different workpiece sizes and shapes.

4. Customization and Integration: Double-acting hydraulic cylinders can be customized and integrated into manufacturing machinery to meet specific pressing and clamping requirements. Manufacturers can design cylinders with varying sizes, capacities, and mounting options to fit the machinery and application needs. The modular nature of hydraulic systems allows for easy integration and interchangeability of cylinders, ensuring compatibility with existing manufacturing equipment.

5. Safety Features: Manufacturing machinery incorporating double-acting hydraulic cylinders often incorporates safety features to ensure safe operation during pressing and clamping processes. These may include pressure relief valves, emergency stop mechanisms, and safety interlocks. These features help protect operators, prevent excessive forces or unexpected movements, and provide fail-safe operation.

Given their suitability for pressing and clamping operations, precise force and stroke control, customization and integration capabilities, as well as the inclusion of safety features, double-acting hydraulic cylinders are widely integrated into manufacturing machinery. Their reliable performance and versatility make them essential components in achieving efficient and accurate pressing and clamping processes in various manufacturing industries.

How does a double-acting hydraulic cylinder differ from a single-acting one?

A double-acting hydraulic cylinder and a single-acting hydraulic cylinder differ in their functionality and ability to generate force. Here’s a detailed explanation of the differences:

1. Functionality: A double-acting hydraulic cylinder can generate force in both directions of its stroke, whereas a single-acting hydraulic cylinder can only generate force in one direction.

2. Construction: In a double-acting hydraulic cylinder, there are two hydraulic ports—one connected to the rod end and the other to the cap end of the cylinder. This allows hydraulic fluid to enter and exit both chambers of the cylinder, enabling force generation in both directions. In contrast, a single-acting hydraulic cylinder has only one hydraulic port, typically connected to the cap end. The rod end of a single-acting cylinder is often vented or equipped with a smaller hydraulic port to facilitate the return of the piston.

3. Operation: A double-acting hydraulic cylinder operates by supplying hydraulic fluid to the appropriate ports to extend or retract the piston. By controlling the flow and pressure of the hydraulic fluid, operators can regulate the direction and speed of the piston’s movement, generating pushing and pulling forces. In a single-acting hydraulic cylinder, hydraulic fluid is supplied to the port to extend the piston and generate force in one direction. The return stroke of the piston is accomplished by the force of gravity or an external mechanical load, as there is no hydraulic pressure applied to retract the piston.

4. Applications: Due to their ability to generate force in both directions, double-acting hydraulic cylinders are suitable for applications that require bidirectional force, precise control, and versatility. They are commonly used in tasks such as lifting, pushing, pulling, clamping, and more. Single-acting hydraulic cylinders, on the other hand, are often employed in applications where force is required in only one direction, such as in simple lifting or lowering tasks.

5. Efficiency: Double-acting hydraulic cylinders offer improved efficiency compared to single-acting cylinders in applications that require frequent or continuous bidirectional force. With a double-acting cylinder, the force can be applied in both the extension and retraction strokes, allowing for increased productivity and reduced cycle times.

In summary, the main difference between a double-acting hydraulic cylinder and a single-acting hydraulic cylinder lies in their ability to generate force in one or both directions. While a double-acting cylinder can generate force in both directions, a single-acting cylinder can generate force in only one direction. This distinction impacts their construction, operation, applications, and efficiency in various hydraulic systems.

editor by CX 2023-12-23