Product Description

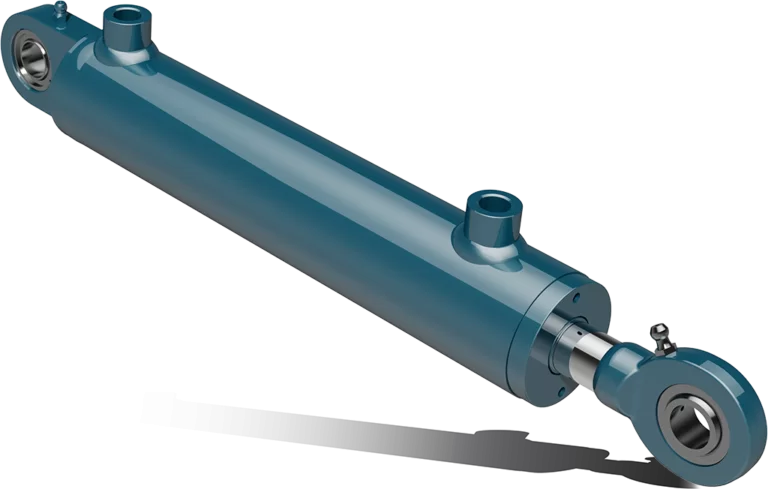

Double acting cylinder/hydraulic cylinder used in agriculture industry/Farm

Product Description

|

Material |

Cast steel ;cast iron |

| Weight Ranges |

0.05-100kg |

|

Tolernace |

Controlled by ISO 8062 CT4-6 |

|

Design Support |

Pro-E, UG,SolidWorks,AutoCad, PDF |

|

Quality Control |

Material, Dimension,Performance,inside defects,Balance test |

|

Standard |

ASTM,DIN,JIS,ISO,GB standards |

Products show:

Declaration:

Products shown herein are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within CHINAMFG group of companies.

Our policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

Company Information

HangZhou New CHINAMFG Casting and Forging Company is the sales company of HangZhou CHINAMFG Group of Companies. Features of New CHINAMFG simply summarized as below:

1. Trusted supplier of steel, iron & non-ferrous components;

2. Extensive documented quality program in place.

3. Castings, forgings, stampings, machining, welding & fabrication services.

4. 9 related factories, over 50 joint-venture sub-contractors.

5. 25+ years of manufacturing experiences, 10+ years of exporting experience

6. 100% of products sold to overseas customers.

7. 50% of customer base is forturne 500 companies.

Factory

3rd Party Inspection:

New Densen worked as 3rd party inspection center besides its sister factories or sub-contractors’ self inspection, Offers process inspection, random inspection and before delivedry inspection services for material, mechanical, inside defects, dimentional, pressure, load, balance, surface treatment, visual inspection and test. Weekly project follow-up report together with pictures and videos, full quality inspection documentation available.

New CHINAMFG also designed as 3rd party inspection representative for several customers when their products made by other suppliers.

Application:

Contact us

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Clay Dry Sand |

|---|---|

| Casting Method: | Thermal Gravity Casting |

| Sand Core Type: | Resin Sand Core |

| Application: | Instrument Accessories |

| Machining: | CNC Machining |

| Material: | Steel, Stainless Steel |

| Customization: |

Available

|

|

|---|

Can double-acting hydraulic cylinders be employed in material handling equipment for pushing and pulling?

Yes, double-acting hydraulic cylinders are commonly employed in material handling equipment for pushing and pulling tasks. Here’s a detailed explanation:

1. Pushing Function: Double-acting hydraulic cylinders can generate significant pushing force, making them well-suited for material handling equipment that requires pushing capabilities. By supplying pressurized hydraulic fluid to one side of the cylinder, the piston extends, exerting force in the desired direction. This force can be utilized to push heavy objects, such as crates, pallets, or machinery components. The ability to generate substantial pushing force allows material handling equipment to move or position loads efficiently.

2. Pulling Function: In addition to pushing, double-acting hydraulic cylinders can also be employed for pulling tasks in material handling equipment. By supplying fluid to the opposite side of the cylinder, the piston retracts, creating a pulling force. This pulling force enables the equipment to tow or drag objects, such as trailers or carts, facilitating material transport within a facility or across a worksite.

3. Bi-Directional Force Generation: The bi-directional operation of double-acting hydraulic cylinders is advantageous for both pushing and pulling applications. By utilizing both the extension and retraction strokes, material handling equipment can generate force in both directions, enhancing versatility and productivity. The ability to generate force in multiple directions allows for efficient maneuvering, positioning, and handling of various loads, contributing to the overall effectiveness of the material handling process.

4. Control and Precision: Double-acting hydraulic cylinders provide precise control over the pushing and pulling forces exerted by material handling equipment. The hydraulic system can be designed with valves, control systems, and pressure regulation mechanisms to adjust and fine-tune the force output. This level of control enables operators to apply the necessary force with precision, preventing damage to the handled materials or equipment. The ability to control and modulate the force also ensures the safety of operators and enhances the overall efficiency of material handling operations.

5. Adaptability and Customization: Double-acting hydraulic cylinders can be adapted and customized to meet the specific requirements of material handling equipment. They can be designed with different stroke lengths, bore sizes, and mounting configurations to fit the equipment’s structure and hydraulic system. This adaptability allows for seamless integration of the hydraulic cylinders into the material handling equipment, optimizing performance, and ensuring efficient pushing and pulling operations.

Given their capability for pushing and pulling functions, bi-directional force generation, control and precision, as well as adaptability and customization, double-acting hydraulic cylinders are widely employed in material handling equipment for efficient and effective pushing and pulling tasks.

How does a double-acting hydraulic cylinder handle variations in cylinder size and capacity?

A double-acting hydraulic cylinder is designed to handle variations in cylinder size and capacity effectively. Here’s a detailed explanation:

1. Modular Design: Double-acting hydraulic cylinders are often built with a modular design, allowing for flexibility in cylinder size and capacity. The modular approach means that different components, such as the cylinder barrel, piston, and rod, can be easily interchanged or replaced to accommodate varying size and capacity requirements. This modularity enables hydraulic cylinders to be customized and adapted to specific applications, ensuring optimal performance and efficiency.

2. Standardized Sizing: Hydraulic cylinders, including double-acting ones, often adhere to standard sizing conventions. These standards specify the dimensions and capacities of cylinders based on widely accepted industry norms. By following standardized sizing, hydraulic cylinder manufacturers ensure compatibility and interchangeability of components. This facilitates the selection and replacement of cylinders with appropriate size and capacity to meet specific application needs.

3. Pressure and Flow Control: Double-acting hydraulic cylinders can handle variations in cylinder size and capacity by adjusting the pressure and flow of hydraulic fluid. The hydraulic system supplying the cylinder can be equipped with valves, regulators, and control mechanisms to regulate the pressure and flow rates. By adjusting these parameters, operators can control the force generated by the cylinder, compensating for variations in size and capacity. This allows for consistent and precise force application, regardless of the specific cylinder dimensions.

4. Load Calculation and System Design: When designing hydraulic systems that incorporate double-acting cylinders, load calculations and system design considerations are essential. Engineers assess the intended load requirements and select cylinders with appropriate size and capacity to handle those loads. By accurately calculating the forces involved and selecting cylinders with suitable specifications, the hydraulic system can effectively handle variations in cylinder size and capacity, ensuring safe and efficient operation.

5. Performance Testing and Certification: Double-acting hydraulic cylinders undergo rigorous testing and certification processes to ensure their performance and reliability. Manufacturers conduct various tests, including pressure testing, load testing, and endurance testing, to verify that cylinders meet the specified size and capacity ratings. By adhering to industry standards and obtaining certifications, manufacturers provide assurance that their cylinders can handle variations in size and capacity within the specified limits, maintaining consistent performance and safety.

Through modular design, standardized sizing, pressure and flow control, load calculation and system design considerations, as well as performance testing and certification, double-acting hydraulic cylinders are well-equipped to handle variations in cylinder size and capacity. These features ensure that hydraulic systems can be tailored to specific requirements, providing reliable and efficient operation across a range of applications in various industries.

Can double-acting hydraulic cylinders be customized for specific machinery and equipment?

Yes, double-acting hydraulic cylinders can be customized to meet the specific requirements of machinery and equipment. Here’s a detailed explanation:

1. Size and Dimension: Double-acting hydraulic cylinders can be customized in terms of size and dimension to fit the available space and installation requirements of the machinery or equipment. The cylinder’s length, diameter, and mounting options can be adjusted to ensure a proper fit and integration with the existing system.

2. Force and Stroke Capacity: Hydraulic cylinders can be customized to provide the desired force and stroke capacity based on the machinery’s operational needs. The diameter of the piston, the size of the rod, and the hydraulic pressure can be tailored to achieve the required force output and stroke length, ensuring optimal performance.

3. Seal and Material Selection: The choice of seals and materials used in the construction of double-acting hydraulic cylinders can be customized to suit specific applications. Different seal materials, such as rubber or polyurethane, can be selected based on factors like temperature, pressure, and compatibility with the working fluid. Similarly, the cylinder’s body material can be chosen to withstand corrosive environments or heavy-duty operations.

4. Mounting and Connection Options: Hydraulic cylinders can be customized with various mounting and connection options to facilitate easy installation and integration into the machinery or equipment. Mounting styles such as flange mounts, trunnion mounts, or clevis mounts can be selected based on the specific mounting requirements. Similarly, connection options for hydraulic hoses or fittings can be customized to ensure compatibility with the existing hydraulic system.

5. Sensor Integration: For applications that require feedback or control, double-acting hydraulic cylinders can be customized to integrate sensors or position feedback devices. These sensors can provide information about the cylinder’s position, velocity, or force, allowing for precise control and monitoring of the machinery or equipment.

6. Special Features and Coatings: Depending on the application’s unique needs, double-acting hydraulic cylinders can be customized with special features or coatings. For example, cylinders used in extreme environments may require protective coatings to resist corrosion or abrasion. Cylinders used in high-speed applications may incorporate features such as cushioning mechanisms to dampen impact forces.

7. Testing and Validation: Customized hydraulic cylinders undergo rigorous testing and validation processes to ensure their performance and reliability. These tests may include pressure testing, leakage testing, endurance testing, and functional testing to verify that the cylinder meets the specified requirements and standards.

By offering customization options, double-acting hydraulic cylinder manufacturers can tailor the cylinder’s design, specifications, and features to suit the specific machinery and equipment requirements. This customization capability allows for optimal integration, improved performance, and enhanced efficiency in various industrial applications.

editor by CX 2023-12-22