Product Description

Chinese Manufacture Boom Cylinder Dump Truck Use Hydraulic Cylinder Telescopic

Product Features

| ITEM | FEATURES |

| Material | Carbon Steel,Alloy Steel,Stainless Steel,27SiMn,SAE1045(45#),SAE1571(20#),16Mn(Q345B),Bronze Parts, etc. |

| Honed Tube | 40-300mm, Cold Drawn, Heat Treatment, Honing, Rolling, Forging |

| Piston Rod | 30-280mm, Ground & Polished, Plated Nickel or Hard Chrome or Ceramic |

| Seal Kit | 1. Parker, Merkel, Hallite, NOK, Trelleborg, Kaden, China Made, etc. 2. Suitable for different working condition and requirements. |

| Technology | Parker,Custom Hoist, Hyco,HYVA, Meiller

SAT,DAT |

| Mounting Type | Pin-eye/Flange/Trunnion/Ball mount/Screw Thread, etc. FC, FE, FEE, FSE,TPIN |

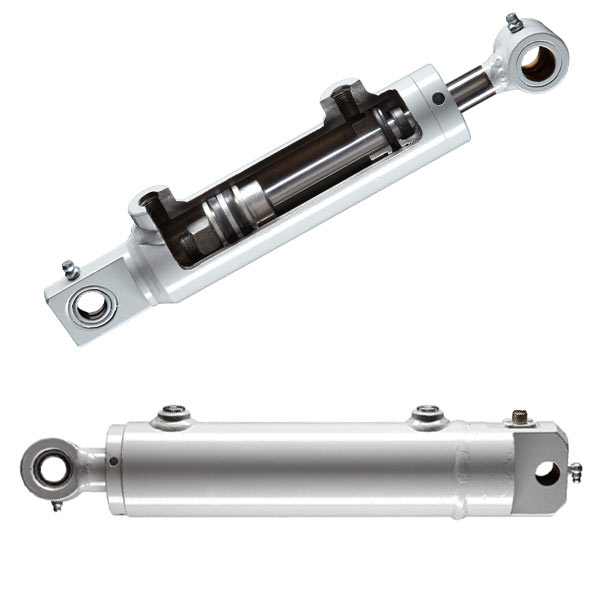

Specification

| Bore Size | 40mm/Customize Request |

| Rod Size | 25mm/Customize Request |

| Stroke | 360mm/Customize Request |

| Working Medium | Hydraulic Oil |

| Working Pressure | 16-20MPa |

| Temperature Range | -20°C to +100°C |

| Painting | 1. High Quality Paint 2. Sandblasting, Primer Paint, Middle Paint, Finish paint 3. Color according to customer demands |

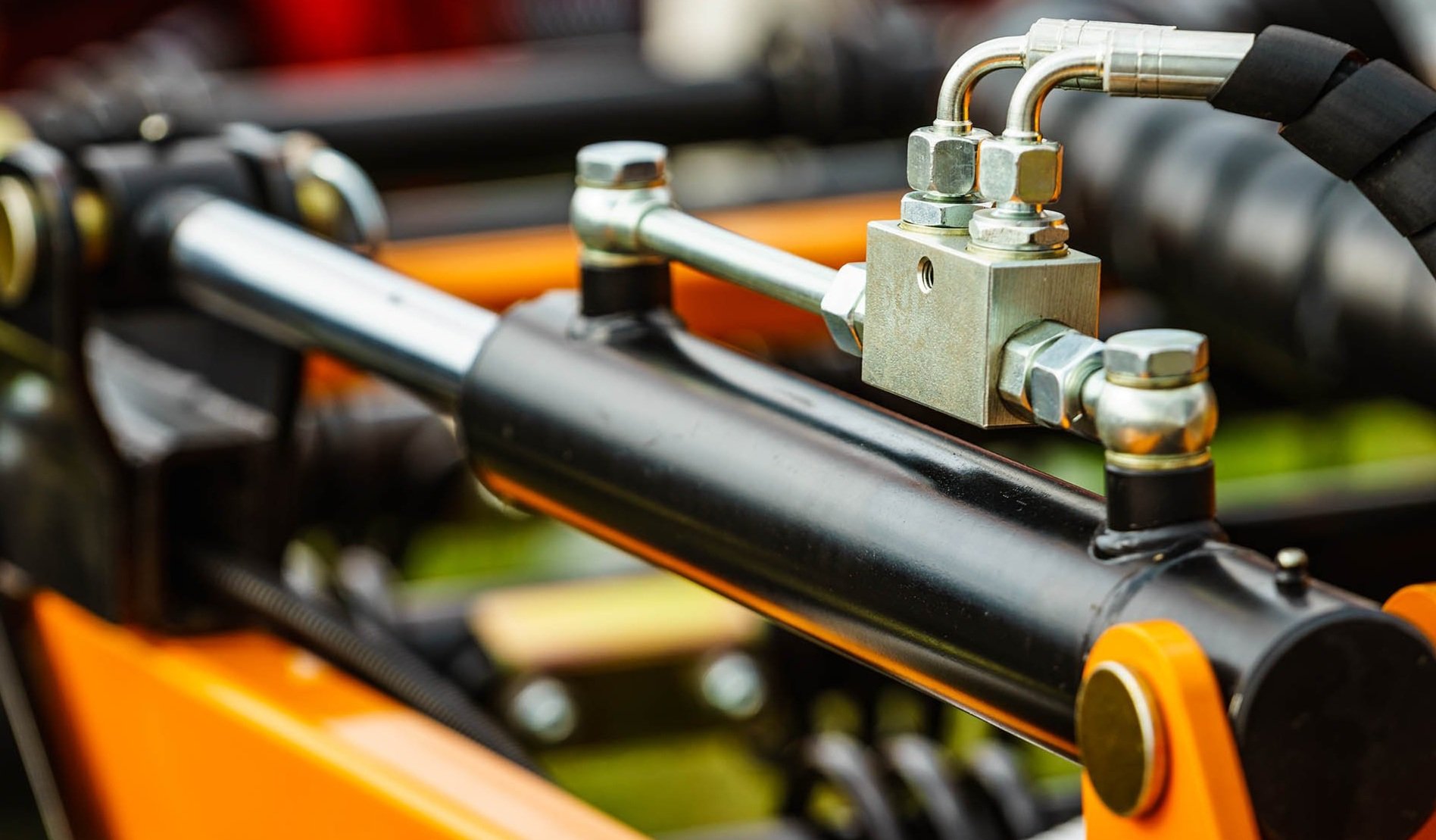

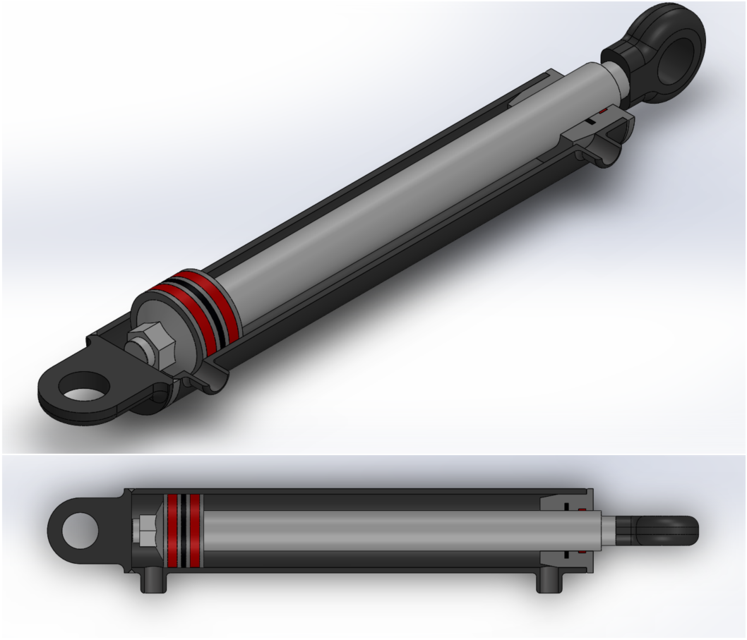

Detailed Photos

Production Process

Warehouse Overview

Product Applications

Excavator is the most widely used construction machinery.

The shock load, harsh working environment, precision movement control require high standards on excavator cylinders.

ROCA guarantees excavator cylinder high performance of abrasion resistance and operation stability in any harsh condition has and gains recognition from every CHINAMFG customer with good quality at a lower cost.

Roca manufactures full-size excavator cylinders for mini excavators to largeexcavators.

Xihu (West Lake) Dis. Mining Group Co., Ltd. is a sizable multinational mining group performing most competitively in Chinese mining industry. CHINAMFG locate in the same CHINAMFG Mining output area, as the mining cylinder plant that grew up in the mining industry, we repair and reman a lot of mining haul truck cylinder. For a decade CHINAMFG has been focused on the production of various types of imported mine-used off-highway trucks & mining trucks.Our cylinders are mainly applied to world-famous brands such as Cat, Komatsu, Hitachi, BELAZ, and other famous international brands.

Single-Acting Telescopic Cylinders

This type of cylinder applies hydraulic pressure in 1 direction only and the return of the telescopic stages is by load such as a truck-trailer.

ROCA single-acting multistage hoists are used widely throughout the transport sector, where they are used in tip trucks servicing agriculture, earthmoving, construction, food processing applications.

Double-Acting Telescopic Cylinder

This type of cylinder is constructed with porting to both the annular and full bore area so hydraulic pressure can be applied to both surfaces and the cylinder stages can move in multiple directions without the need of an outside force, such as gravity.ROCA double-acting multi-stage cylinders are used in a wide variety of applications across many industries where space restrictions prohibit the use of a rod cylinder and require a compact telescopic cylinder design.

There are a wide range of products in the cylinder industry and having a specialist working on behalf of the customer is very important. With our years of experience, our business is positioned to provide prompt service, value and long lasting customer relationships.We work toward getting you better products and better service with competitive price.

Company Profile

HangZhou CHINAMFG is a comprehensive manufacturing enterprise engaged in hydraulic cylinders, excavator attachment, metal casting, hydraulic components with certification approval to meet custom or OEM requirement.

ROCA owned factory offers customer effective-cost product with quality assurance. With its professional and experienced R&D team, CHINAMFG Hydraulic devotes itself to research and develop to optimize products applied in construction, mining, waster management, forestry, agriculture, etc.

1. CHINAMFG Hydraulic parts factory focus on the high quality hydraulic cylinder. Our products are widely used in, refuse and recycling, construction, mining, material handling, agriculture, and every specific industry.

2. GS Machinery foundry produces industrial metal castings include Hydraulic piston pump parts, Valve parts, Construction, Mining Machinery Parts, and Auto Parts.

We accept OEM orders, and especially capable of developing and producing single/double-acting telescopic cylinder for dump truck/trailer, roll-off hoist equipment application.

For more than 10 years, CHINAMFG have provided end users with reliable high quality hydraulic products, which has saved user costs and maximized engineering benefits.

Roca R&D team works with customer to ensure their goal become reality, and their products are the best quality. With our in place best-in-class development group that offers unprecedented service and support.

FAQ

Q1.Do you have MOQ?

Depending on different ideas, Can be negotiated. The larger the quantity is, the competitive the unit price will be.

Q2.Should the customer pay the delivery fee, How much is it?

For the delivery fee, many samples are being requested to be sent, so we must get the delivery fee.

If you tell me to use the appointed Express, you will give me your express account or you will pay according to the Express.

If you do not request, I will choose a cheap one in China.

Q3.How about the after sale service?

1) We will always keep the quality the same as the buyer’s samples and if there is something with the quality, we will make compensation for our customers.

2) We will suggest our packing and take charge in our packing, we will keep the goods safe in the delivery.

3) We will trace the goods from the production to selling, we will solve the problems in the selling for our customers.

Q4.When can I get a price?

We usually quote within 24 hours after we get your inquiry.

Q5: Are you a trade company or manufacturer?

We are a professional manufacturer with our factory.

| Certification: | RoHS, CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | High Temperature |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does a double-acting hydraulic cylinder manage variations in load capacity and weight?

A double-acting hydraulic cylinder is designed to effectively manage variations in load capacity and weight in hydraulic systems. Here’s a detailed explanation:

1. Adjustable Force Output: Double-acting hydraulic cylinders allow for adjustable force output by controlling the hydraulic pressure applied to the cylinder. By adjusting the pressure in the hydraulic system, the force generated by the cylinder can be varied to match the specific load requirements. This feature enables the cylinder to handle variations in load capacity and weight effectively.

2. Mechanical Advantage: Double-acting hydraulic cylinders leverage mechanical advantage to manage variations in load capacity and weight. The cylinder’s design incorporates a larger surface area on the cap end of the piston compared to the rod end. This size difference creates a force amplification effect, allowing the cylinder to exert greater force during the extension stroke. This mechanical advantage enables the cylinder to handle heavier loads and compensate for variations in weight.

3. Pressure Compensation: Double-acting hydraulic cylinders can compensate for variations in load capacity and weight by adjusting the hydraulic pressure in the system. When the load increases, the hydraulic pressure can be increased to generate a higher force output. Conversely, when the load decreases, the pressure can be reduced to match the reduced force requirement. This pressure compensation capability allows the cylinder to adapt to varying load conditions.

4. Position Feedback and Control: To effectively manage variations in load capacity and weight, double-acting hydraulic cylinders can be equipped with position feedback devices and control systems. These devices provide real-time information about the cylinder’s position and can be used to adjust the force output accordingly. By monitoring and controlling the cylinder’s position, the system can respond to changes in load capacity and weight, ensuring optimal performance.

5. Accumulator Integration: Double-acting hydraulic cylinders can be integrated with hydraulic accumulators to manage variations in load capacity and weight. An accumulator is a device that stores hydraulic energy in the form of pressurized fluid. During periods of low load or weight, excess hydraulic energy can be stored in the accumulator. When the load or weight increases, the stored energy can be released to supplement the hydraulic power and provide additional force. This integration helps manage variations in load capacity effectively.

6. System Design and Sizing: Proper system design and sizing play a crucial role in managing variations in load capacity and weight. The hydraulic system, including the double-acting cylinder, should be appropriately sized and selected based on the expected load range. A well-designed system takes into account factors such as the maximum expected load, safety factors, and anticipated variations in weight. By selecting the right cylinder size and ensuring adequate system capacity, variations in load and weight can be effectively managed.

By incorporating these features and considerations, double-acting hydraulic cylinders can effectively manage variations in load capacity and weight, providing reliable and efficient force generation in a wide range of applications.

Can double-acting hydraulic cylinders be applied in mining equipment for material transport?

Yes, double-acting hydraulic cylinders are widely used in mining equipment for material transport. Here’s a detailed explanation:

1. Dump Trucks: Dump trucks are commonly used in mining operations for transporting large quantities of material, such as rocks, ores, and coal. Double-acting hydraulic cylinders are employed in the tipping mechanism of dump trucks. These cylinders provide the necessary force to raise the truck bed, allowing the material to be unloaded at the desired location. The bidirectional force generation of double-acting cylinders enables controlled and efficient tipping of the truck bed, facilitating the rapid and effective transport of materials.

2. Front Shovels and Excavators: Front shovels and excavators are heavy-duty machines used in mining for digging and loading materials onto trucks or conveyor systems. Double-acting hydraulic cylinders are utilized in the boom and bucket mechanisms of these machines. The cylinders provide the force required to extend and retract the boom, as well as to control the bucket’s opening and closing. This allows operators to manipulate the excavator effectively, scoop up materials, and deposit them into transport vehicles or processing equipment.

3. Conveyor Systems: Conveyor systems are extensively used in mining operations to transport bulk materials over long distances. Double-acting hydraulic cylinders are employed in conveyor belt tensioning systems. These cylinders apply force to adjust the tension of the conveyor belt, ensuring proper alignment and preventing slippage. The precise force control offered by double-acting cylinders allows for accurate tension adjustment, optimizing the efficiency and reliability of material transport on the conveyor system.

4. Haulage Systems: Haulage systems, such as underground mine trucks and railcars, are crucial for transporting materials within mining operations. Double-acting hydraulic cylinders are employed in these systems for various functions. For instance, the cylinders can be used to control the opening and closing of doors or gates on mine trucks or railcars, facilitating the loading and unloading of materials. Additionally, hydraulic cylinders can be utilized in braking systems to provide the necessary force for safe and controlled stopping of the haulage vehicles.

5. Lifting and Positioning Equipment: In mining operations, lifting and positioning equipment, such as cranes and hoists, are employed to handle heavy materials and equipment. Double-acting hydraulic cylinders play a vital role in these machines. The cylinders provide the force necessary for lifting, lowering, and positioning loads with precision. Whether it’s lifting large mining equipment or positioning heavy materials, hydraulic cylinders ensure safe and controlled movement, enhancing the efficiency of material transport in mining operations.

Given their applications in dump trucks, front shovels and excavators, conveyor systems, haulage systems, as well as lifting and positioning equipment, double-acting hydraulic cylinders are widely applied in mining equipment for material transport. Their ability to generate precise and controllable forces makes them essential components in ensuring efficient and reliable material handling in the mining industry.

What industries commonly use double-acting hydraulic cylinders in their equipment?

Double-acting hydraulic cylinders are widely used across various industries where controlled linear force is required. Here’s a detailed explanation of the industries that commonly utilize double-acting hydraulic cylinders in their equipment:

1. Manufacturing and Machinery: The manufacturing and machinery industries extensively use double-acting hydraulic cylinders in equipment such as hydraulic presses, material handling systems, assembly lines, robotics, and automation systems. These cylinders provide the necessary force for precise movement, positioning, and operation of components and machinery.

2. Construction and Earthmoving: In the construction and earthmoving sector, double-acting hydraulic cylinders are found in equipment like excavators, backhoes, loaders, bulldozers, cranes, and concrete pumps. They enable the controlled lifting and lowering of heavy loads, extension and retraction of booms and arms, and operation of various hydraulic attachments.

3. Mining and Extraction: Double-acting hydraulic cylinders play a crucial role in mining operations. They are used in equipment such as hydraulic shovels, loaders, crushers, and drilling rigs. These cylinders provide the force necessary for excavation, transportation, and processing of minerals and ores.

4. Agriculture and Farming: In the agricultural sector, double-acting hydraulic cylinders are utilized in machinery and equipment such as tractors, harvesters, sprayers, loaders, and hydraulic implements. They enable functions like lifting and lowering of implements, controlling hydraulic systems for precise operation, and powering attachments such as plows, mowers, and loaders.

5. Automotive and Transportation: Double-acting hydraulic cylinders are employed in various automotive and transportation applications. They are found in vehicle suspension systems, steering mechanisms, hydraulic brakes, dump trucks, garbage trucks, and lifting platforms. These cylinders provide the necessary force for controlled movement, stability, and safety.

6. Aerospace and Aviation: The aerospace and aviation industries utilize double-acting hydraulic cylinders in aircraft landing gear systems, wing flaps, control surfaces, and cargo doors. These cylinders provide the force required for smooth and controlled movement, ensuring safe and efficient operation of aircraft.

7. Marine and Offshore: In the marine and offshore industries, double-acting hydraulic cylinders are used in ship steering systems, hatch covers, cranes, winches, and offshore drilling equipment. They enable precise control of movements and operations in challenging marine environments.

8. Energy and Power Generation: Double-acting hydraulic cylinders are employed in power generation equipment such as hydroelectric turbines and gates, wind turbine pitch systems, and steam turbine control systems. They enable the precise control of mechanical components and the generation of force in both directions.

These are some of the major industries where double-acting hydraulic cylinders are commonly used. However, their versatility and ability to provide bidirectional force make them applicable in many other sectors that require controlled linear force in their equipment and machinery.

editor by CX 2023-12-15