Product Description

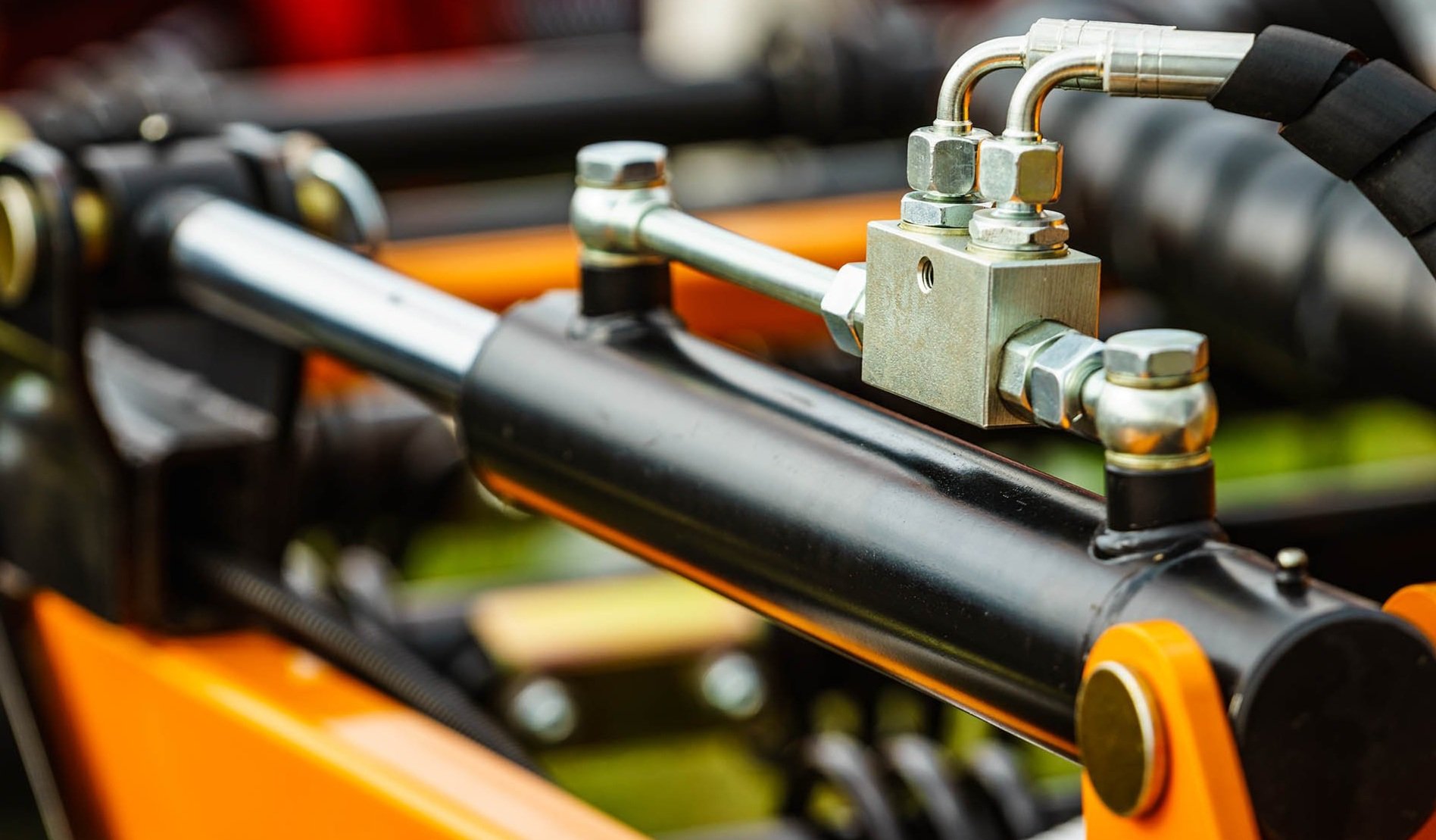

This hydraulic cylinder is specially designed for high-end agricultural machinery.

It is the first choice for the manufacturer of high-end agricultural machinery.

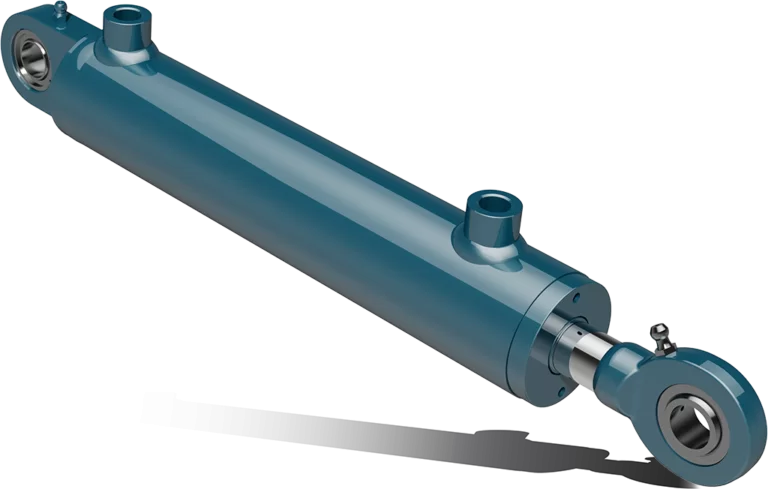

| Model | Bore Diameter (mm) |

Rod Diameter (mm) |

Stroke (mm) |

Nominal Pressure (bar) |

| HSG50/40-75*342-00 | 50 | 40 | 75 | 21 |

| Certification: | ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Customization: |

Available

|

|

|---|

How does a double-acting hydraulic cylinder manage variations in load capacity and weight?

A double-acting hydraulic cylinder is designed to effectively manage variations in load capacity and weight in hydraulic systems. Here’s a detailed explanation:

1. Adjustable Force Output: Double-acting hydraulic cylinders allow for adjustable force output by controlling the hydraulic pressure applied to the cylinder. By adjusting the pressure in the hydraulic system, the force generated by the cylinder can be varied to match the specific load requirements. This feature enables the cylinder to handle variations in load capacity and weight effectively.

2. Mechanical Advantage: Double-acting hydraulic cylinders leverage mechanical advantage to manage variations in load capacity and weight. The cylinder’s design incorporates a larger surface area on the cap end of the piston compared to the rod end. This size difference creates a force amplification effect, allowing the cylinder to exert greater force during the extension stroke. This mechanical advantage enables the cylinder to handle heavier loads and compensate for variations in weight.

3. Pressure Compensation: Double-acting hydraulic cylinders can compensate for variations in load capacity and weight by adjusting the hydraulic pressure in the system. When the load increases, the hydraulic pressure can be increased to generate a higher force output. Conversely, when the load decreases, the pressure can be reduced to match the reduced force requirement. This pressure compensation capability allows the cylinder to adapt to varying load conditions.

4. Position Feedback and Control: To effectively manage variations in load capacity and weight, double-acting hydraulic cylinders can be equipped with position feedback devices and control systems. These devices provide real-time information about the cylinder’s position and can be used to adjust the force output accordingly. By monitoring and controlling the cylinder’s position, the system can respond to changes in load capacity and weight, ensuring optimal performance.

5. Accumulator Integration: Double-acting hydraulic cylinders can be integrated with hydraulic accumulators to manage variations in load capacity and weight. An accumulator is a device that stores hydraulic energy in the form of pressurized fluid. During periods of low load or weight, excess hydraulic energy can be stored in the accumulator. When the load or weight increases, the stored energy can be released to supplement the hydraulic power and provide additional force. This integration helps manage variations in load capacity effectively.

6. System Design and Sizing: Proper system design and sizing play a crucial role in managing variations in load capacity and weight. The hydraulic system, including the double-acting cylinder, should be appropriately sized and selected based on the expected load range. A well-designed system takes into account factors such as the maximum expected load, safety factors, and anticipated variations in weight. By selecting the right cylinder size and ensuring adequate system capacity, variations in load and weight can be effectively managed.

By incorporating these features and considerations, double-acting hydraulic cylinders can effectively manage variations in load capacity and weight, providing reliable and efficient force generation in a wide range of applications.

How does a double-acting hydraulic cylinder handle variations in hydraulic hose technology?

A double-acting hydraulic cylinder can accommodate variations in hydraulic hose technology. Here’s a detailed explanation:

1. Connection Flexibility: Double-acting hydraulic cylinders feature versatile connection options, allowing them to adapt to different hydraulic hose technologies. The cylinder typically has threaded ports or flanges designed to accept various types of hydraulic fittings. This flexibility enables the connection of different types of hydraulic hoses, including those with variations in size, material, and connection method.

2. Pressure and Flow Compatibility: Hydraulic hose technology has evolved to provide compatibility with a wide range of pressure and flow requirements. Double-acting hydraulic cylinders can handle these variations by being designed and manufactured to withstand different pressure ratings. The cylinder is selected or customized based on the system’s maximum operating pressure, ensuring its capability to handle the specific hydraulic hose technology being used. Similarly, the cylinder’s internal design and dimensions are optimized to accommodate the required flow rate, ensuring efficient operation.

3. Sealing Mechanisms: Double-acting hydraulic cylinders incorporate sealing mechanisms to ensure the integrity of the hydraulic system, regardless of the specific hose technology being employed. The cylinder is equipped with seals, such as O-rings or lip seals, that create a reliable barrier against fluid leakage. These seals are designed to accommodate variations in hose technology, providing a secure and leak-free connection between the hydraulic cylinder and the hydraulic hoses.

4. Compatibility with Hose Materials: Hydraulic hoses are available in different materials, including rubber, thermoplastic, and metal. Double-acting hydraulic cylinders are designed to be compatible with a wide range of hose materials. The cylinder’s construction and internal components are selected and engineered to withstand the characteristics of different hose materials, such as their flexibility, temperature resistance, and chemical compatibility. This ensures that the hydraulic cylinder can operate seamlessly with various hose technologies, providing reliable and efficient force generation.

5. Customization and Adaptability: Double-acting hydraulic cylinders can be customized and adapted to specific hydraulic hose technologies. They can be designed with different port sizes, thread types, or flange configurations to match the specific requirements of the hydraulic hoses being used. This adaptability allows for easy integration and ensures a secure and efficient hydraulic connection between the cylinder and the hoses, regardless of any variations in hose technology.

Overall, the connection flexibility, pressure and flow compatibility, sealing mechanisms, compatibility with hose materials, as well as customization and adaptability of double-acting hydraulic cylinders enable them to handle variations in hydraulic hose technology. This ensures the reliable and efficient operation of hydraulic systems, regardless of the specific hose technology employed.

What is a double-acting hydraulic cylinder and how does it function?

A double-acting hydraulic cylinder is a type of hydraulic cylinder that can generate force in both directions of its stroke. Here’s a detailed explanation of its function:

1. Design and Construction: A double-acting hydraulic cylinder consists of a cylindrical barrel, a piston, and two hydraulic ports. The barrel is sealed at both ends, and the piston divides the interior of the cylinder into two chambers. The hydraulic ports are connected to a hydraulic system, allowing the flow of hydraulic fluid into and out of the cylinder.

2. Functionality: The double-acting hydraulic cylinder operates using hydraulic pressure to extend and retract the piston, generating force in both directions. Here’s how it functions:

– Extension Stroke: When hydraulic fluid is supplied to the port connected to the rod end of the cylinder, it enters the cylinder’s rod-end chamber. The pressure of the hydraulic fluid pushes against the piston, causing it to move away from the rod end and extend the cylinder’s rod. This extension stroke generates a pushing force at the rod end of the cylinder.

– Retraction Stroke: Conversely, when hydraulic fluid is supplied to the port connected to the cap end of the cylinder, it enters the cylinder’s cap-end chamber. The pressure of the hydraulic fluid pushes against the piston from the opposite direction, causing it to move towards the rod end and retract the cylinder’s rod. This retraction stroke generates a pulling force at the rod end of the cylinder.

3. Sealing Mechanism: To ensure efficient operation, double-acting hydraulic cylinders incorporate sealing mechanisms. These seals prevent hydraulic fluid leakage between the piston and the cylinder barrel, maintaining the separation of the two chambers.

4. Control and Application: The operation of double-acting hydraulic cylinders is controlled by the hydraulic system supplying and retracting hydraulic fluid. By controlling the flow and pressure of the hydraulic fluid, operators can regulate the extension and retraction speeds and precisely control the force generated by the cylinder. Double-acting hydraulic cylinders find applications in various industries, including manufacturing, construction, mining, agriculture, and more, where controlled linear force is required for tasks such as lifting, pushing, pulling, and clamping.

In summary, a double-acting hydraulic cylinder is a hydraulic component capable of generating force in both directions of its stroke. By supplying hydraulic fluid to the appropriate ports, the cylinder extends or retracts its piston, creating pushing or pulling forces. The sealing mechanism ensures efficient operation, and the control of hydraulic fluid flow allows for precise force control. Double-acting hydraulic cylinders are widely used in diverse industries for a range of applications that require controlled linear force.

editor by CX 2023-12-12