Product Description

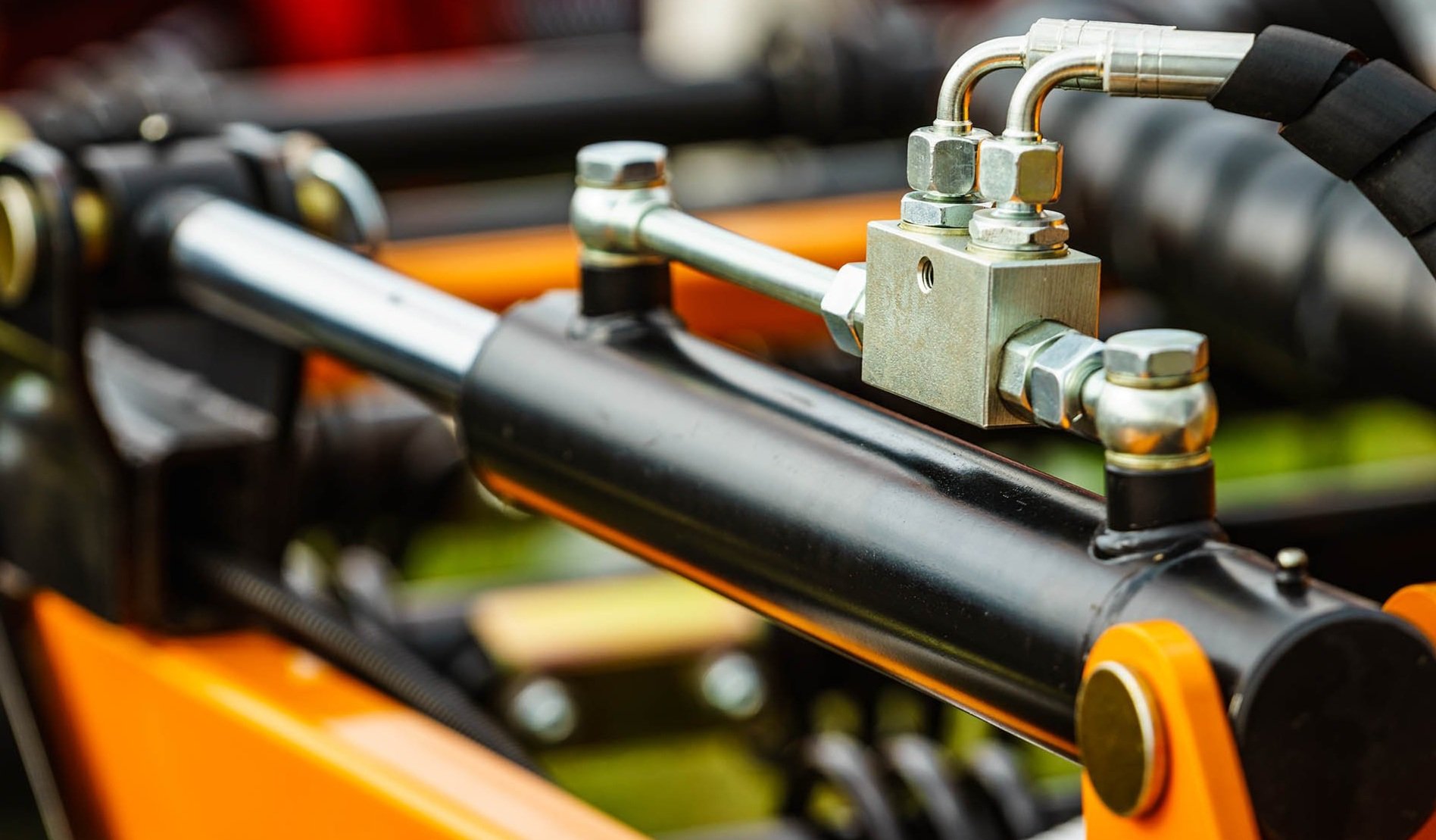

HYDRAULIC CYLINDER

Widely used in equipment for Construction, Coal&mine, Agriculture , Aerial work table and Environmental sanitation etc.

| Features | customized hydraulic cylinder |

| Bore Diameter | 2′-50’/50-1500mm |

| Rod Diameter | 1′ – 60’/25 -1000 mm |

| Wall Thickness | 0.1′-4’/3-100 mm |

| Max Stroke | 366’/9280 mm |

| Max Pressure | 9600 psi/600 bar |

| Test Pressure | 14500 psi/1000 bar |

| Material | 20#,40#,45#,16Mn,27SiMn,etc |

| Seal Kits | Hallite, Parker, NOK, DICHTOMATIK, Trelleborg, Merkel |

| Dimensional Accuracy | H7-H11 |

| Bore Roughness | Ra 0.4-1.6mm |

| Coating | hard chrome |

| Purpose | engineering, Coal &mining, agricultural machinery, environmental sanitation |

| OEM/ODM | Yes |

| MOQ | 1 Piece |

| Certificates | ISO9001,CE, CCS |

Q1. Are you a manufacturer?

Yes, we have manufactured hydraulic cylinders for over 30 years. They are widely used in Engineers, Coal&mine, Agriculture and Environmental Sanitation etc.

Q2. Do your products come with a warranty?

Yes, we have 1 year warranty.

Q3. Can we customize our products from you?

Yes, actually 70% of our products are customized for our clients. You just need to let us know your demand (specifications &drawing is better), and we shall realize them for you.

Q4. How do you deliver the products?

By sea, by plane, or by couriers.

Q5. How many days the samples can be finished, And how about the mass production?

Generally 5-7days for samples making. The lead time of mass production will depend on quality, production art and so on. Generally 35days.

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | -40~120 |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Structure: | Piston Type |

| Customization: |

Available

|

|

|---|

What safety considerations are important when working with double-acting hydraulic cylinders?

Working with double-acting hydraulic cylinders requires careful attention to safety to prevent accidents and ensure the well-being of operators and nearby personnel. Here are some important safety considerations:

1. Proper Training and Familiarity: Operators and maintenance personnel should receive proper training on the safe operation and maintenance of hydraulic systems, including double-acting cylinders. They should be familiar with the cylinder’s functions, controls, and potential hazards. Adequate training helps prevent errors and promotes safe handling practices.

2. System Design and Installation: The hydraulic system, including the double-acting cylinder, should be designed and installed by qualified professionals following appropriate industry standards and guidelines. Proper design ensures the system’s integrity, efficiency, and safety. It is essential to consider factors such as load capacity, pressure ratings, and proper component selection during system design.

3. Pressure Relief and Emergency Stop: Hydraulic systems should incorporate pressure relief valves or devices to prevent excessive pressure buildup. These safety mechanisms protect the cylinder from overloading and potential failure. Additionally, an emergency stop or shutdown system should be in place to quickly halt the hydraulic operation in case of an emergency or hazardous situation.

4. Regular Maintenance and Inspection: Routine maintenance and inspection of double-acting hydraulic cylinders are crucial for identifying and addressing potential issues before they lead to accidents or failures. Regular checks should include inspecting for leaks, damaged seals, loose connections, and signs of wear. Proper lubrication, fluid level checks, and filter replacements should also be part of the maintenance routine.

5. Lockout/Tagout Procedures: When performing maintenance, repair, or adjustment tasks on hydraulic systems, proper lockout/tagout procedures must be followed. Lockout/tagout ensures that all energy sources are isolated and the system is in a safe, de-energized state to prevent unexpected movement or activation of the hydraulic cylinder. Lockout/tagout procedures should be clearly defined and strictly adhered to.

6. Personal Protective Equipment (PPE): Operators and personnel working with double-acting hydraulic cylinders should wear appropriate personal protective equipment (PPE). This may include safety glasses, gloves, protective clothing, and steel-toe boots. PPE helps protect against potential hazards such as hydraulic fluid leaks, flying debris, or accidental contact with moving parts.

7. Risk Assessment and Hazard Mitigation: Prior to working with double-acting hydraulic cylinders, a thorough risk assessment should be conducted to identify potential hazards and implement appropriate hazard mitigation measures. This assessment should consider factors such as pressure, force, pinch points, and potential for hydraulic fluid injection injuries. Safeguards such as guards, warning signs, or interlock systems should be implemented accordingly.

8. Proper Lifting and Support: When lifting or supporting loads using double-acting hydraulic cylinders, it is essential to follow safe lifting practices. This includes ensuring that the load is within the cylinder’s rated capacity, using proper rigging techniques, and providing adequate support to prevent unintentional movement or instability.

9. Communication and Signaling: Clear communication and signaling protocols should be established when working with hydraulic systems. Operators and personnel should use standardized signals and verbal communication to ensure coordination and prevent accidents caused by miscommunication or misunderstanding.

10. Emergency Preparedness: Adequate emergency preparedness measures should be in place, including the availability of first aid kits, fire extinguishers, and emergency evacuation plans. Personnel should be trained on emergency response procedures to handle potential incidents effectively.

By adhering to these safety considerations, operators and personnel can minimize risks associated with working with double-acting hydraulic cylinders and create a safer working environment.

Can double-acting hydraulic cylinders be used in automotive repair and maintenance?

Yes, double-acting hydraulic cylinders can be extensively used in automotive repair and maintenance. Here’s a detailed explanation:

1. Lifting and Lowering Vehicles: Double-acting hydraulic cylinders are commonly employed in automotive lifts and jacks for lifting and lowering vehicles. These cylinders provide the necessary force to raise vehicles off the ground, allowing mechanics to access the underside of the vehicle for repairs, maintenance, or inspections. The bidirectional force generation of double-acting cylinders enables precise control over the lifting and lowering process, ensuring the safety and stability of the vehicle during automotive tasks.

2. Pressing and Clamping: Automotive repair often involves pressing or clamping components together during assembly or disassembly processes. Double-acting hydraulic cylinders can be used in hydraulic presses or clamping devices to provide the required force. By supplying hydraulic pressure to one side of the cylinder, the piston extends, applying force to press or clamp components together. By supplying pressure to the other side, the piston retracts, releasing the pressure. This capability allows for precise and controlled pressing or clamping operations in automotive repair and maintenance.

3. Brake and Suspension System Maintenance: Double-acting hydraulic cylinders play a vital role in brake and suspension system maintenance. For example, when bleeding brake lines, a hydraulic cylinder can be used to pressurize the brake system and force the air bubbles out of the brake fluid. Similarly, in suspension system maintenance, hydraulic cylinders can be employed to compress or decompress suspension components, facilitating repairs or replacements. The precise force control offered by double-acting cylinders ensures accurate and effective maintenance of these critical automotive systems.

4. Engine Hoists and Tilters: Engine repair and maintenance often require lifting, tilting, or removing heavy engines from vehicles. Double-acting hydraulic cylinders are utilized in engine hoists and tilters to provide the necessary force for these tasks. The cylinders can be integrated into lifting mechanisms, allowing controlled lifting and tilting of engines for access to various components or for engine removal and installation. The precise force application of double-acting cylinders ensures the safe handling of heavy engine assemblies.

5. Wheel Alignment and Balancing: Double-acting hydraulic cylinders are also used in wheel alignment and balancing equipment. These cylinders provide the force required to adjust wheel angles and balance tires accurately. By applying precise force to the wheel clamps or alignment mechanisms, the cylinders enable mechanics to align wheels correctly and achieve balanced tire rotations, ensuring optimal vehicle performance, safety, and tire longevity.

Given their applications in lifting and lowering vehicles, pressing and clamping operations, brake and suspension system maintenance, engine hoisting and tilting, as well as wheel alignment and balancing, double-acting hydraulic cylinders are indispensable in automotive repair and maintenance. Their precise force control and versatility make them valuable tools for mechanics and technicians in the automotive industry.

What is the importance of hydraulic fluid in a double-acting hydraulic cylinder?

Hydraulic fluid plays a crucial role in the operation and performance of a double-acting hydraulic cylinder. Here’s a detailed explanation of its importance:

1. Transmitting Power: Hydraulic fluid is the medium through which power is transmitted in a hydraulic system. In a double-acting hydraulic cylinder, the hydraulic fluid is used to transfer force from the hydraulic pump to the piston, generating the necessary pushing and pulling forces. The fluid’s ability to transmit power efficiently is vital for the cylinder’s operation.

2. Lubrication and Cooling: Hydraulic fluid provides lubrication to the moving components within the cylinder, such as the piston, rod, and seals. This lubrication minimizes friction and wear, ensuring smooth operation and extending the cylinder’s service life. Additionally, the hydraulic fluid absorbs heat generated during operation and carries it away from the cylinder, contributing to cooling and preventing overheating.

3. Sealing and Contamination Control: The hydraulic fluid helps create a seal between the piston and cylinder walls through the use of seals and gaskets. This seal prevents leakage of fluid and maintains the integrity of the hydraulic system. The fluid also plays a vital role in contamination control by carrying away particles and debris that may enter the system, protecting the cylinder’s internal components from damage.

4. Energy Transfer and Efficiency: Hydraulic fluid acts as a medium for energy transfer within the hydraulic system. It stores potential energy when pressurized by the hydraulic pump and releases it when needed to move the piston. The fluid’s incompressible nature ensures efficient energy transfer, allowing for precise control and effective operation of the double-acting hydraulic cylinder.

5. Compatibility and Performance Optimization: The choice of hydraulic fluid is essential to ensure compatibility with the cylinder’s materials, seals, and other hydraulic system components. Different types of hydraulic fluids, such as mineral oil-based, synthetic, or water-based fluids, offer varying performance characteristics. Selecting the appropriate hydraulic fluid and maintaining its quality through regular maintenance helps optimize the cylinder’s performance and prevent potential issues.

6. System Safety and Reliability: The hydraulic fluid’s properties, such as viscosity and temperature range, are critical for maintaining system safety and reliability. The fluid’s viscosity affects the cylinder’s response time and the system’s overall performance. Monitoring and maintaining the appropriate fluid level and quality are essential for safe and reliable operation of the double-acting hydraulic cylinder.

In conclusion, hydraulic fluid is of utmost importance in a double-acting hydraulic cylinder. It enables power transmission, provides lubrication and cooling, ensures sealing and contamination control, facilitates energy transfer and efficiency, optimizes performance, and contributes to system safety and reliability.

editor by CX 2023-12-08