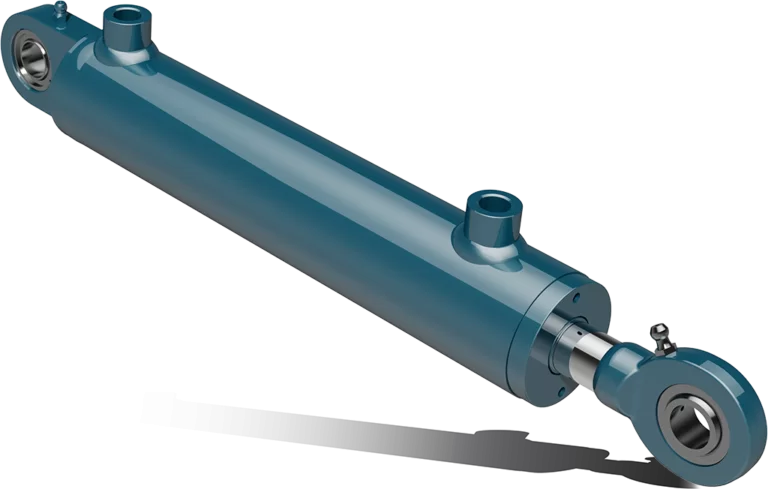

Product Description

Product Description

| CW-A-10T Overall Dimension | ||||

| Total Stroke | Power Stroke | L | L1 | L2 |

| 50 | 5 | 305 | 480 | 393 |

| 100 | 5 | 355 | 580 | 443 |

| 150 | 5 | 405 | 680 | 493 |

| 200 | 5 | 455 | 780 | 543 |

| 50 | 10 | 305 | 480 | 457 |

| 100 | 10 | 355 | 580 | 507 |

| 150 | 10 | 405 | 680 | 557 |

| 200 | 10 | 455 | 780 | 607 |

| 50 | 15 | 305 | 480 | 521 |

| 100 | 15 | 355 | 580 | 571 |

| 150 | 15 | 405 | 680 | 621 |

| 200 | 15 | 455 | 780 | 671 |

| 50 | 20 | 305 | 530 | 635 |

| 100 | 20 | 355 | 580 | 635 |

| 150 | 20 | 405 | 680 | 685 |

| 200 | 20 | 455 | 780 | 735 |

Specification

| Action type | Double action |

| Action pressure | Clean compressed air of 3-7kg/cm² |

| Action-wear hydraulicoil | Anti-wear hydraulic oil of VG 68# |

| Operation temperature | 0-55ºC |

| Operating speed | 10-400mm/s |

| Anti-pressure of oil tank | 300kg/cm² |

| Anti-pressure of pneumatic cylinder | 12kg/cm² |

| Prepress stroke tolerance | +1.00mm 0.00mm |

| Power stroke tolerance | +0.20mm 0.00mm |

| Operation frequency | 10-50 times (related to the specific pre-pressure and booster stroke) |

| High pressure Boosting force | 1-80T(the actual output tonnage according to the customer demand) |

Product Features

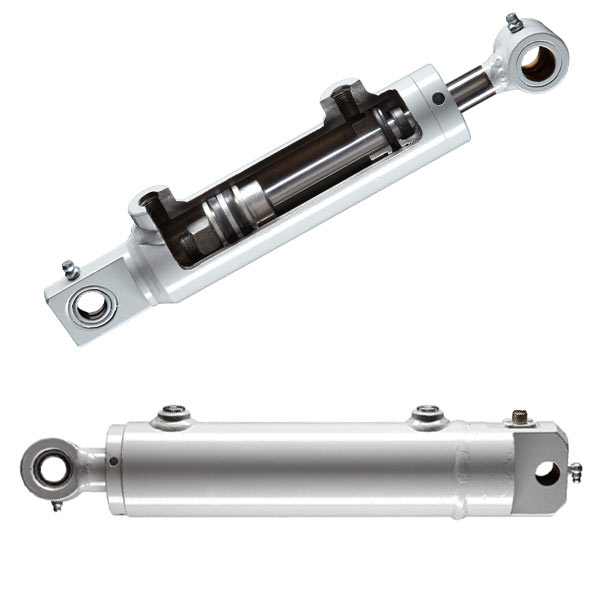

Working Principle

pneumatic cylinder is combined the oil pressure cylinder and booster together for taking pure gas press as the power source. It makes use of the different size of booster, the crosssection area compression ratio and Pascal energy conservation principle. Because of constant pressure, when the compression area change from small to large, the press would vary with the size, so as to raise the gas pressure to tens. Taking the prepress standard hydro pneumatic cylinder as an example: When the work gas pressed on the hydraulic oil (or working piston) surface, hydraulic oil would flow to the approach stroke cavity because of the air pressure, then the hydraulic oil would promote the workpiece to move rapidly. When the workpiece is meet the resistance larger than the gas pressure, it stops moving. At this point, the booster cavity start moving because of the signal (or pneumatic signal), then achieve the purpose of moding products!

Features:

1.Fast speed: The action speed is faster than the hydraulic drive and it is more stability than pneumatic drive;

2.High output: It can reach the highest output of oil hydraulic machine under same conditions, which can not be achieved by the pure pneumatic machine;

3.Low price: The price is lower than the oil pressure system;

4.Easy to maintain: The simple structure is easier to maintain than the oil pressure system;

5.Low energy consumption: When continue to boost or stop moving, it does not need the motor to keep working as the hydraulic system,

then the energy can be saved. And it is convenient to take the power source, so the actual energy

consumption is equivalent to 10%-30% of hydraulic power system;

6.No leakage: Energy conversion is easy with zero leakage, so not worry about the environmental pollution;

7.No harm to the die: In order to meet the technology needs, stamping pressure and the work stroke can keep within the provided area without adjustable levels;

8.Soft landing: Soft-stamping technology reduce the noise to protect the die;

9.Fault less: No temperature rising problems unlike the hydraulic system;

10.Small space: Space area can be less than 50% compare with normal air cylinder and hydraulic station;

Factory Display

Packaging

Company Introduction

CHINAMFG Machinery Equipment Co.,Ltd supply a wide range of high quality punching machine, hydraulic press machine, automatic riveting machine,eyelet punching machine, hydro pneumatic press machine,air liquid booster pump, pneumatic hydraulic components and other automation equipment. Committed to the complete solution from design to manufacturing to meet customer demand.

Our company has a professional technical team, nearly 30 years of experience in this area. Our products are widely used in aerospace, new energy, automobile and boating, petrochemical, mold, clothing and other fields.Our products are exported to Europe, South America, North America, southeast Asia, South Africa and other places.

CHINAMFG has always adhered to the principle of “Integrity, Professionalism, Technology and Innovation”,to provide high quality solutions to the customers and all aspects of service, strive to make the world love made in China.Corporate Philosophy: Integrity as Root, Customer-Based Culture; Science and Technology Innovation. Sharina and Co-Win.

Certifications

Professional technical team, nearly 30 years of industry experience;

Lean production management mode combines market demand, product research and development, production and manufacturing.pre-sales quality and after-sales service;

Advanced equipment, mature technology, with a number of independent intellectual vproperty rights;

Complete quality control, assured quality, from raw material procurement,production process control, to finished product inspection, packaging, full field monitoring traceability, to ensure that every product qualified;

Has 3 specialized processing and manufacturing factories, sufficient inventory, short delivery time;

Support customized, design according to customer requirements to meet the diversified demand of customers;

Perfect after-sales service system and after-sales quality tracking system;

Professional sales system, rich experience in export related operation process.

| Material: | Steel |

|---|---|

| Usage: | Automation and Control |

| Structure: | Piston Cylinder |

| Power: | Pneumatic |

| Standard: | Nonstandard |

| Pressure Direction: | Double-acting Cylinder |

| Customization: |

Available

|

|

|---|

Can double-acting hydraulic cylinders be repaired or maintained when needed?

Yes, double-acting hydraulic cylinders can be repaired and maintained when needed. Here’s a detailed explanation:

1. Inspection and Diagnosis: When a double-acting hydraulic cylinder requires repair or maintenance, the first step is to conduct a thorough inspection and diagnosis. This involves examining the cylinder for any visible damage, leaks, or signs of wear. Additionally, the hydraulic system and associated components should be checked for proper operation and potential issues. Through inspection and diagnosis, the specific problem or maintenance requirement can be identified.

2. Seal Replacement: One of the most common maintenance tasks for double-acting hydraulic cylinders is seal replacement. Seals, such as piston seals and rod seals, are critical components that prevent fluid leakage and maintain system integrity. Over time, seals can wear out or become damaged, leading to leaks and reduced performance. By replacing worn or damaged seals, the cylinder’s functionality can be restored.

3. Component Repair or Replacement: Depending on the nature and extent of the issue, specific components of the double-acting hydraulic cylinder may need repair or replacement. This can include repairing or replacing damaged pistons, rods, glands, or other internal parts. In cases where the damage is extensive or the component is beyond repair, a complete replacement may be necessary.

4. Fluid and Filter Maintenance: Proper fluid and filter maintenance is essential for the optimal performance and longevity of hydraulic cylinders. Regular fluid checks, fluid level adjustments, and fluid replacements are part of routine maintenance. Similarly, filters should be inspected and replaced as needed to prevent contamination and ensure the cleanliness of the hydraulic fluid.

5. Lubrication: Lubrication is vital for the smooth operation of double-acting hydraulic cylinders. Lubrication points, such as pivot points and sliding surfaces, should be regularly lubricated with the appropriate lubricant. This helps reduce friction, wear, and potential damage to the cylinder components.

6. Testing and Calibration: After repairs or maintenance activities, it is important to perform testing and calibration to ensure that the double-acting hydraulic cylinder is functioning correctly. This may involve checking for proper operation, verifying the cylinder’s force output, and conducting leakage tests. Testing and calibration help validate the effectiveness of the repair or maintenance work.

7. Preventive Maintenance: Implementing a preventive maintenance program is highly recommended to proactively address potential issues and extend the lifespan of double-acting hydraulic cylinders. This includes regular inspections, scheduled maintenance tasks, and adherence to manufacturer-recommended service intervals. Preventive maintenance helps identify and address problems before they cause significant damage or system failures.

8. Professional Assistance: In complex repair or maintenance situations, or when specialized knowledge is required, seeking professional assistance is advisable. Hydraulic system experts or certified technicians can provide the necessary expertise and ensure that repairs and maintenance are conducted safely and effectively.

By performing regular maintenance and addressing repairs promptly, double-acting hydraulic cylinders can be kept in optimal condition, ensuring their reliable operation and longevity.

How does a double-acting hydraulic cylinder contribute to precise force application?

A double-acting hydraulic cylinder plays a crucial role in enabling precise force application. Here’s a detailed explanation:

1. Control over Force Generation: Double-acting hydraulic cylinders provide precise control over the force they generate. By supplying pressurized hydraulic fluid to one side of the cylinder, the piston extends, exerting force in a specific direction. By supplying fluid to the other side, the piston retracts, creating an opposite force. The hydraulic system can be designed with valves, control systems, and pressure regulation mechanisms to adjust and fine-tune the force output. This level of control allows operators to apply the necessary force with precision, whether it’s for lifting, pushing, pulling, or any other task.

2. Adjustable Pressure: The hydraulic system powering the double-acting cylinder allows for adjustable pressure settings. By regulating the hydraulic pressure, operators can precisely control the force output of the cylinder. This adjustability is especially useful when handling delicate or sensitive materials that require a specific amount of force to avoid damage. By fine-tuning the pressure, operators can ensure that the force applied is precisely tailored to the requirements of the task at hand.

3. Smooth and Gradual Force Application: Double-acting hydraulic cylinders facilitate smooth and gradual force application. The hydraulic fluid in the system is incompressible, which means that force is distributed evenly throughout the system. As the hydraulic fluid is pressurized, the force is transmitted to the piston, resulting in a smooth and controlled movement. This allows for gentle and gradual force application, minimizing the risk of sudden or jarring movements that could damage the equipment or the materials being handled.

4. Position and Stroke Control: Double-acting hydraulic cylinders provide precise control over the position and stroke of the piston. The hydraulic fluid can be regulated to stop the piston at specific positions, allowing for precise positioning of loads or equipment. Additionally, the stroke length of the cylinder can be adjusted to control the range of motion. This level of control over position and stroke enables operators to apply force with precision, ensuring accurate and repeatable results in various applications.

5. Feedback and Monitoring: Advanced hydraulic systems can incorporate feedback mechanisms and sensors to monitor and provide real-time information about the force being applied by the double-acting hydraulic cylinder. This feedback allows operators to monitor the force levels, make adjustments if necessary, and ensure that the desired force is being accurately applied. By having access to this information, operators can maintain precise control over force application throughout the operation.

Overall, through control over force generation, adjustable pressure settings, smooth and gradual force application, position and stroke control, as well as feedback and monitoring capabilities, double-acting hydraulic cylinders contribute significantly to precise force application. Their ability to provide controlled and tailored force output makes them essential components in applications where accuracy and precision are paramount.

How does a double-acting hydraulic cylinder differ from a single-acting one?

A double-acting hydraulic cylinder and a single-acting hydraulic cylinder differ in their functionality and ability to generate force. Here’s a detailed explanation of the differences:

1. Functionality: A double-acting hydraulic cylinder can generate force in both directions of its stroke, whereas a single-acting hydraulic cylinder can only generate force in one direction.

2. Construction: In a double-acting hydraulic cylinder, there are two hydraulic ports—one connected to the rod end and the other to the cap end of the cylinder. This allows hydraulic fluid to enter and exit both chambers of the cylinder, enabling force generation in both directions. In contrast, a single-acting hydraulic cylinder has only one hydraulic port, typically connected to the cap end. The rod end of a single-acting cylinder is often vented or equipped with a smaller hydraulic port to facilitate the return of the piston.

3. Operation: A double-acting hydraulic cylinder operates by supplying hydraulic fluid to the appropriate ports to extend or retract the piston. By controlling the flow and pressure of the hydraulic fluid, operators can regulate the direction and speed of the piston’s movement, generating pushing and pulling forces. In a single-acting hydraulic cylinder, hydraulic fluid is supplied to the port to extend the piston and generate force in one direction. The return stroke of the piston is accomplished by the force of gravity or an external mechanical load, as there is no hydraulic pressure applied to retract the piston.

4. Applications: Due to their ability to generate force in both directions, double-acting hydraulic cylinders are suitable for applications that require bidirectional force, precise control, and versatility. They are commonly used in tasks such as lifting, pushing, pulling, clamping, and more. Single-acting hydraulic cylinders, on the other hand, are often employed in applications where force is required in only one direction, such as in simple lifting or lowering tasks.

5. Efficiency: Double-acting hydraulic cylinders offer improved efficiency compared to single-acting cylinders in applications that require frequent or continuous bidirectional force. With a double-acting cylinder, the force can be applied in both the extension and retraction strokes, allowing for increased productivity and reduced cycle times.

In summary, the main difference between a double-acting hydraulic cylinder and a single-acting hydraulic cylinder lies in their ability to generate force in one or both directions. While a double-acting cylinder can generate force in both directions, a single-acting cylinder can generate force in only one direction. This distinction impacts their construction, operation, applications, and efficiency in various hydraulic systems.

editor by CX 2023-11-30