Product Description

Product Description

A: Product Description

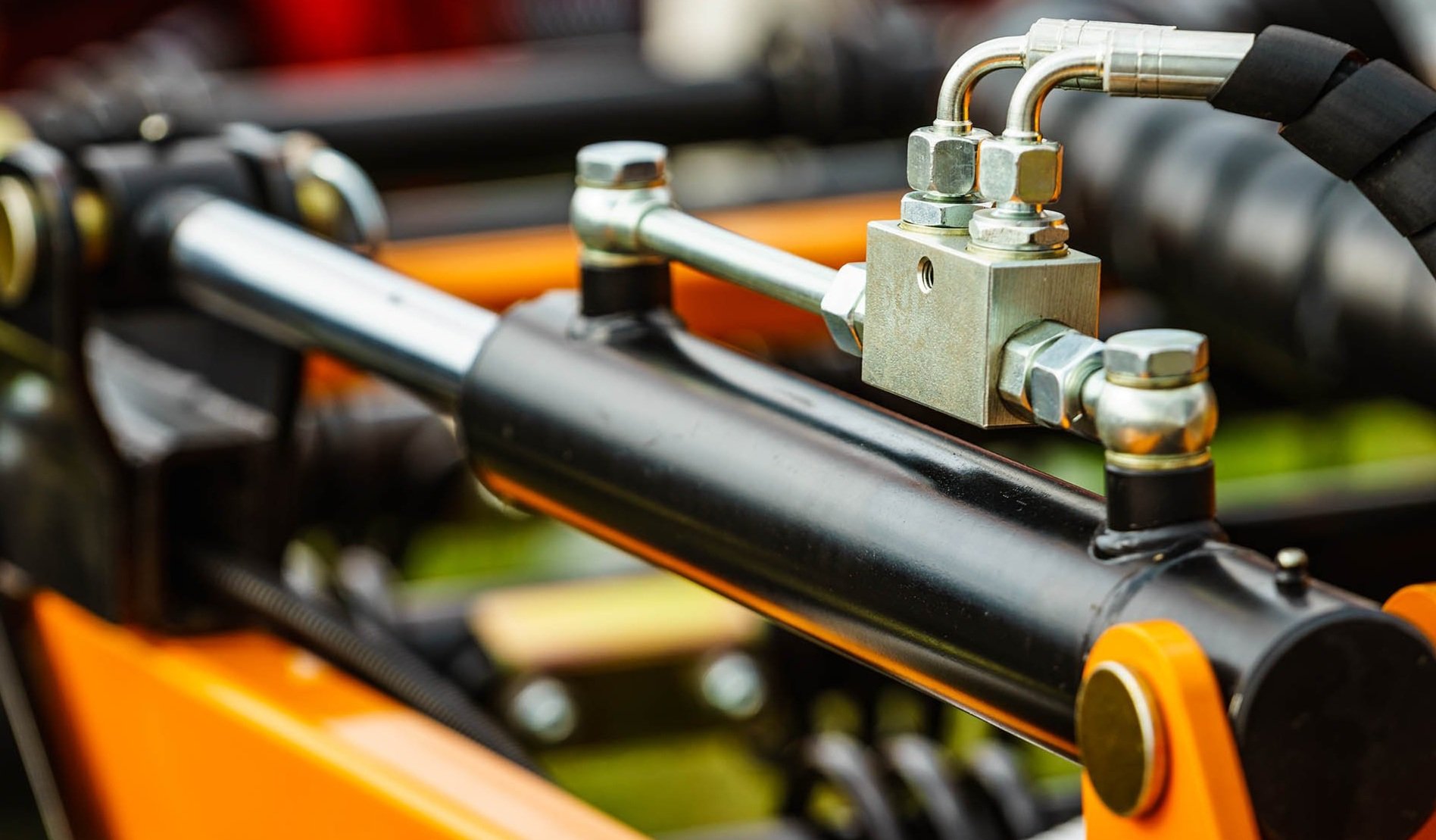

| Commodity Name | telescopic cylinder, telescopic hydraulic cylinder |

| Suitable Model | dump truck, dump tractor |

| Original | ZheJiang , China |

| Warranty | One year |

| Min of quantity | 1 piece |

| Packing | standard export wooden box or as your require |

| Time of Shipment | Usual 30-60days. Different according the quantity of order. |

| Port of Delivery | HangZhou, China |

Product Parameters

Supply Ability Supply Ability 3000 Pieces per Month

*We can customize and design according to your needs

*We can also produce according to your drawings

*If you need any hydraulic cylinder, please feel free to contact us

1.Use thickened steel, long service life

2.Smooth surface and good sealing

3.High color fastness

Products are used in highway, railway, bridge, subway, construction, shipbuilding, mining, foundation settlement test, static

pressure pile, pile foundation detection and other industries

Our service/certifications

—CE Certificate of Quality Checked

—Adopt ISO Certificate of Quality Management System

—BV Certificate of Main Products Line verification

—Fast Delivery

—After-sales Service

—24 Hours, 7 Days on-line Service

Process of processing

Company Profile

KENDE is a leading global designer, manufacturer and marketer of hydraulic cylinder,cab, oil tank, counterweight, boom, arm, bucket, chassis, outrigger, pipe, hose, fitting, valve block, tyre, wheel,and other parts. Products are widely used in construction, mining, crane, material handing, automobile, truck, transportation, oil and gas, farm and garden equipment and so on .

We supply a wide range of parts for excavators, loaders, drills, dumpers, forklifts, tractors, trailers, harvestors, cars, buses, trucks and so on. Our products are focused on improved efficiency and life of the machineries and equipments.

Founded in January of 2015, we have become a big group till now which has 3 factories in asia to supply a wide range of products and service for the global customers.

We have the most advanced production equipments and specialized R &D center to assure the highest quality products to customers.

Our vision statement is “Science and technology first, Always with a grateful heart, Walk the world by virtue, Struggle for a better future”

Our Advantages

Certifications

FAQ

FAQ

1)>. How about your delivery time?

: Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

2)>. What is your terms of price?

: EXW, FOB, CFR, CIF, DDU.

3)> . What is your terms of payment?

: T/T 50% as deposit, and 50% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

4)> . Can you supply a sample freely?

: Sorry, we only can produce the sample with the cost price for you.

5)> Can you produce according to the samples?

: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

6)>. What is your sample policy?

: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

7)>. Do you test all your goods before delivery?

: Yes, we have 100% test before delivery

8)>: How do you make our business long-term and good relationship?

:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

| Pressure: | High Pressure Low Pressure Medium Pressure |

|---|---|

| Work Temperature: | High Temperature Low Temperature Normal Temperat |

| Acting Way: | Double Acting Single Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Structure: | Piston Type |

| Customization: |

Available

|

|

|---|

Can double-acting hydraulic cylinders be applied in both mobile and stationary machinery?

Yes, double-acting hydraulic cylinders can be applied in both mobile and stationary machinery. Here’s a detailed explanation:

1. Mobile Machinery: Double-acting hydraulic cylinders find extensive use in various types of mobile machinery. These include construction equipment such as excavators, loaders, and bulldozers, where hydraulic cylinders are utilized for tasks like lifting, digging, and pushing. Agricultural machinery such as tractors, harvesters, and sprayers also employ hydraulic cylinders for functions like raising and lowering attachments, steering, and operating implements. Additionally, hydraulic cylinders are employed in material handling equipment, such as forklifts and cranes, for lifting, lowering, and moving heavy loads. The ability of double-acting hydraulic cylinders to generate bi-directional force and provide precise control makes them well-suited for the dynamic and versatile requirements of mobile machinery.

2. Stationary Machinery: Double-acting hydraulic cylinders are equally applicable in stationary machinery across various industries. In industrial manufacturing, hydraulic cylinders are used in presses, machine tools, and assembly equipment for tasks like clamping, pressing, and forming. They are also employed in the mining and quarrying industry for equipment such as rock crushers and conveyors, providing force for crushing, conveying, and material handling operations. Stationary hydraulic lifts and platforms, such as scissor lifts or dock levelers, rely on hydraulic cylinders for vertical movement and positioning. The versatility and controllability of double-acting hydraulic cylinders make them suitable for precise and reliable operation in stationary machinery.

3. Adaptability: Double-acting hydraulic cylinders offer adaptability that allows them to be applied in both mobile and stationary machinery. They can be designed and manufactured to meet specific requirements, such as different stroke lengths, bore sizes, and mounting configurations, ensuring compatibility with a wide range of applications. Hydraulic systems, including double-acting cylinders, can also be integrated into both mobile and stationary machinery designs, providing a common and standardized power transmission solution. This adaptability enables the use of double-acting hydraulic cylinders in diverse machinery across various industries.

4. Maintenance and Service: Double-acting hydraulic cylinders can be maintained and serviced in both mobile and stationary machinery. Regular maintenance activities such as seal replacement, fluid checks, and lubrication can be performed to ensure optimal performance and longevity. In the case of repairs or component replacements, hydraulic cylinders can be disassembled, repaired, or replaced as needed, regardless of whether they are installed in mobile or stationary machinery.

Given their versatility, adaptability, and maintenance capabilities, double-acting hydraulic cylinders are widely employed in both mobile and stationary machinery, meeting the demanding requirements of diverse industries.

Can double-acting hydraulic cylinders be used in automotive repair and maintenance?

Yes, double-acting hydraulic cylinders can be extensively used in automotive repair and maintenance. Here’s a detailed explanation:

1. Lifting and Lowering Vehicles: Double-acting hydraulic cylinders are commonly employed in automotive lifts and jacks for lifting and lowering vehicles. These cylinders provide the necessary force to raise vehicles off the ground, allowing mechanics to access the underside of the vehicle for repairs, maintenance, or inspections. The bidirectional force generation of double-acting cylinders enables precise control over the lifting and lowering process, ensuring the safety and stability of the vehicle during automotive tasks.

2. Pressing and Clamping: Automotive repair often involves pressing or clamping components together during assembly or disassembly processes. Double-acting hydraulic cylinders can be used in hydraulic presses or clamping devices to provide the required force. By supplying hydraulic pressure to one side of the cylinder, the piston extends, applying force to press or clamp components together. By supplying pressure to the other side, the piston retracts, releasing the pressure. This capability allows for precise and controlled pressing or clamping operations in automotive repair and maintenance.

3. Brake and Suspension System Maintenance: Double-acting hydraulic cylinders play a vital role in brake and suspension system maintenance. For example, when bleeding brake lines, a hydraulic cylinder can be used to pressurize the brake system and force the air bubbles out of the brake fluid. Similarly, in suspension system maintenance, hydraulic cylinders can be employed to compress or decompress suspension components, facilitating repairs or replacements. The precise force control offered by double-acting cylinders ensures accurate and effective maintenance of these critical automotive systems.

4. Engine Hoists and Tilters: Engine repair and maintenance often require lifting, tilting, or removing heavy engines from vehicles. Double-acting hydraulic cylinders are utilized in engine hoists and tilters to provide the necessary force for these tasks. The cylinders can be integrated into lifting mechanisms, allowing controlled lifting and tilting of engines for access to various components or for engine removal and installation. The precise force application of double-acting cylinders ensures the safe handling of heavy engine assemblies.

5. Wheel Alignment and Balancing: Double-acting hydraulic cylinders are also used in wheel alignment and balancing equipment. These cylinders provide the force required to adjust wheel angles and balance tires accurately. By applying precise force to the wheel clamps or alignment mechanisms, the cylinders enable mechanics to align wheels correctly and achieve balanced tire rotations, ensuring optimal vehicle performance, safety, and tire longevity.

Given their applications in lifting and lowering vehicles, pressing and clamping operations, brake and suspension system maintenance, engine hoisting and tilting, as well as wheel alignment and balancing, double-acting hydraulic cylinders are indispensable in automotive repair and maintenance. Their precise force control and versatility make them valuable tools for mechanics and technicians in the automotive industry.

How does a double-acting hydraulic cylinder handle variations in hydraulic pressure?

A double-acting hydraulic cylinder is designed to handle variations in hydraulic pressure while maintaining its functionality and performance. Here’s a detailed explanation:

1. Balanced Design: Double-acting hydraulic cylinders are designed with a balanced piston and rod arrangement. This design ensures that the hydraulic pressure acts equally on both sides of the piston, allowing for consistent and balanced force generation. As a result, the cylinder can handle variations in hydraulic pressure without compromising its ability to extend and retract smoothly.

2. Efficient Sealing System: Double-acting cylinders incorporate a sealing system that helps maintain the integrity of the hydraulic fluid and prevents leakage. The piston and rod seals, typically made of materials like rubber or polyurethane, create a tight seal between the piston and the cylinder barrel. This sealing system ensures that hydraulic pressure is effectively contained within the cylinder, reducing the impact of pressure variations on the cylinder’s performance.

3. Pressure Relief Mechanism: In situations where there are significant variations in hydraulic pressure, double-acting hydraulic cylinders may incorporate a pressure relief mechanism. This mechanism allows excess pressure to be released from the cylinder, preventing damage to the seals and other internal components. Pressure relief valves or adjustable relief valves are commonly used to regulate the pressure within the cylinder and protect it from excessive pressure fluctuations.

4. Robust Construction: Double-acting hydraulic cylinders are constructed using high-strength materials such as steel or aluminum. This robust construction enables the cylinder to withstand variations in hydraulic pressure without deformations or failures. The materials used, along with proper engineering and manufacturing techniques, ensure the structural integrity of the cylinder even under challenging pressure conditions.

5. Performance Testing and Quality Control: Manufacturers of double-acting hydraulic cylinders subject their products to rigorous performance testing and quality control measures. These tests evaluate the cylinder’s ability to handle variations in hydraulic pressure, ensuring that it meets the required performance and safety standards. Through these quality control processes, any potential issues related to pressure variations are identified and addressed before the cylinder is deployed.

By employing a balanced design, efficient sealing system, pressure relief mechanisms, robust construction, and thorough quality control, double-acting hydraulic cylinders can effectively handle variations in hydraulic pressure. These features ensure the cylinder’s reliability, longevity, and consistent performance in diverse hydraulic systems and applications.

editor by CX 2023-10-29