Product Description

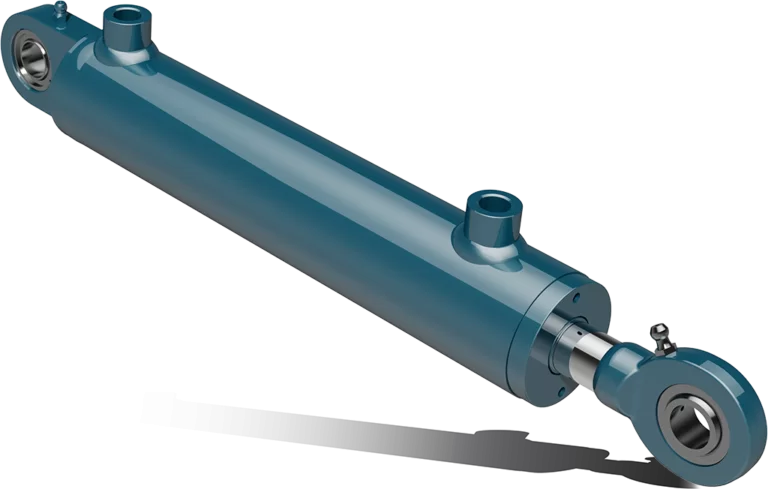

10.5MPa 15kg Double Acting Hydraulic Forklift Steering Cylinder Replacement of Toyata

The forklift steering cylinder is a hydraulic component responsible for controlling the movement of the steering mechanism on a forklift. It enables the operator to steer the forklift by transmitting hydraulic force to the wheels, allowing them to turn in the desired direction. It’s important to note that the design and configuration of the forklift steering cylinder can vary among different forklift models and manufacturers. Therefore, it is recommended to consult the specific forklift’s manual or the manufacturer’s guidelines for accurate information regarding the steering cylinder and its maintenance procedures.

| bore diameter (D) | rod diameter (d) | stroke (S) | Installation distance (L) | working pressure | Interface dimensions (M) | weight |

| Φ65 | Φ40 | 2*98 | 672 | 10.5MPa | 2-G1/4 | 15kg |

(1) Our company can customize non-standard oil cylinders within the range of cylinder diameter D360MM and stroke L6000MM according to customer requirements;

(2) The above product prices are nontax unit prices, excluding packaging and transportation costs required for the export

Here are some critical applications of the forklift right lifting cylinder:

1. Function: The steering cylinder converts hydraulic pressure into linear motion, which is used to actuate the steering mechanism. When the operator turns the steering wheel or operates the steering control, hydraulic fluid is directed to the steering cylinder, causing the piston rod to extend or retract. This movement is transmitted to the steering mechanism and ultimately results in the turning of the forklift’s wheels.

2. Structure: The steering cylinder typically consists of a cylinder barrel, piston rod, seals, and hydraulic connections. The cylinder barrel houses the piston attached to the piston rod. The seals ensure proper sealing and prevent hydraulic fluid leakage. The cylinder is mounted to the forklift’s chassis, and the piston rod is connected to the steering linkage or mechanism.

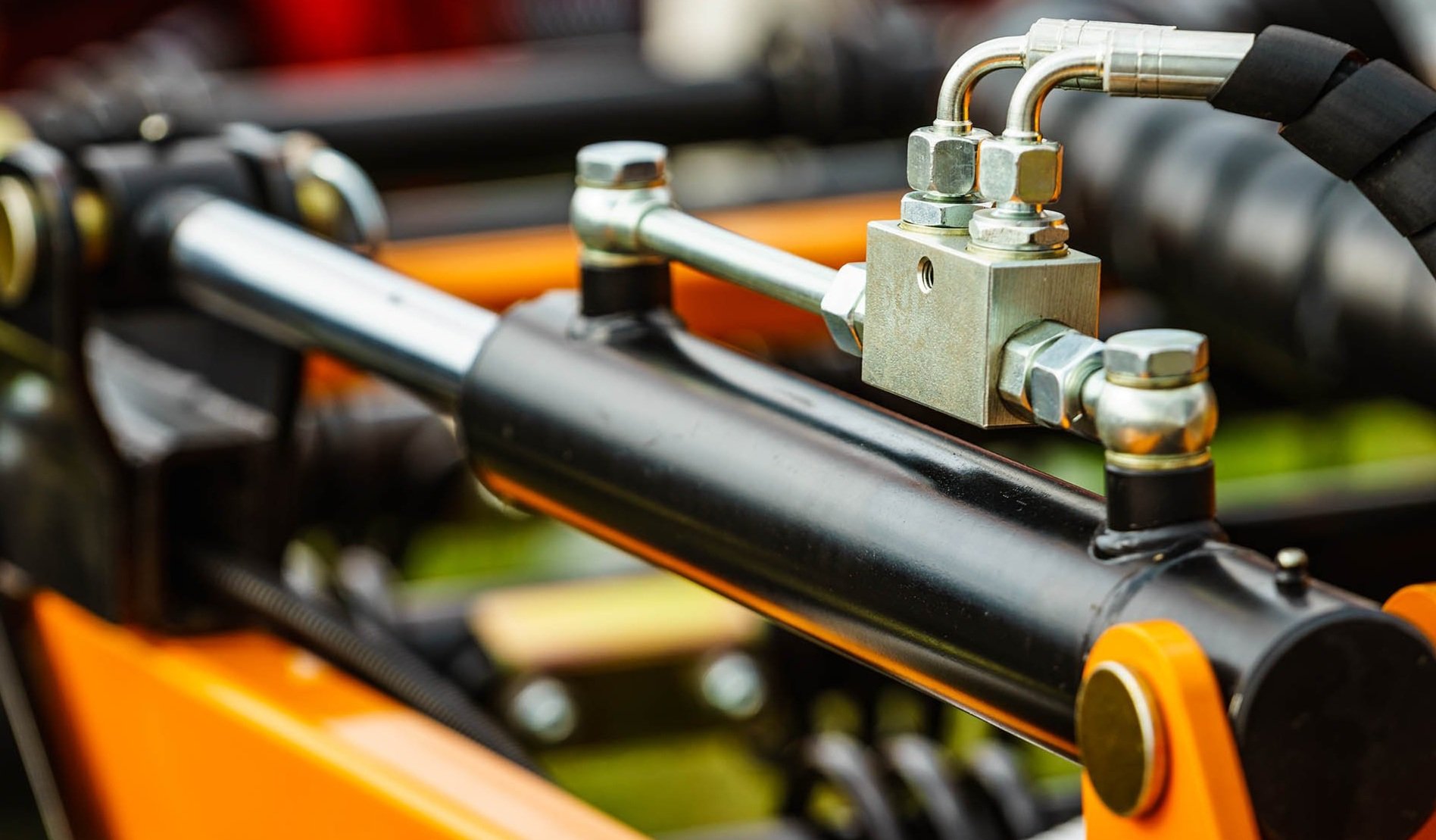

3. Hydraulic System: The forklift steering cylinder is an integral part of the forklift’s hydraulic system. It receives hydraulic fluid from the hydraulic pump, which the operator controls through the steering input. The hydraulic fluid is directed to the steering cylinder via valves and hoses, allowing for the desired steering motion.

4. Steering Control: The forklift steering cylinder is operated by the steering control inputs provided by the operator. This can be in the form of a steering wheel, joystick, or other steering control mechanisms. As the operator turns the steering control, it activates the hydraulic system, which causes the steering cylinder to extend or retract, resulting in the desired steering action.

5. Maintenance: Proper forklift steering cylinder maintenance is crucial for optimal performance. Regular inspections should be conducted to check for any signs of fluid leakage, damaged seals, or misalignment. The hydraulic fluid level and quality should be monitored and maintained according to the manufacturer’s recommendations. Any issues or abnormalities should be addressed promptly to ensure safe and efficient steering operation.

The working principle of forklift steel cylinder

-

Hydraulic System: The forklift’s hydraulic system consists of a pump, hydraulic fluid, valves, hoses, and the hydraulic cylinder. The hydraulic pump pressurizes the hydraulic fluid, which is then directed to the hydraulic cylinder through control valves and hoses.

-

Cylinder Structure: The hydraulic cylinder consists of a cylindrical barrel, a piston, a piston rod, and seals. The barrel is a steel tube with precision-machined internal surfaces. The piston is a cylindrical component that fits inside the barrel and divides it into 2 chambers. The piston rod extends from the piston and is connected to the lifting mechanism, such as the forks or mast.

-

Working Principle: When the operator activates the lift control lever or joystick, hydraulic fluid is directed to the hydraulic cylinder. The pressurized fluid enters 1 side of the cylinder, causing the piston to move. As the piston moves, it pushes the rod, translating the linear motion into a lifting force. The forklift’s load is attached to the lifting mechanism, and the hydraulic cylinder exerts the power necessary to raise or lower the burden.

-

Seals and Fluid Control: The hydraulic cylinder incorporates seals to prevent hydraulic fluid leakage between the piston and the barrel. These seals ensure efficient operation and maintain the pressure required for proper lifting. The control valves in the hydraulic system regulate the flow of hydraulic fluid into and out of the cylinder, enabling precise control of the lifting and lowering functions.

-

Load Holding: Once the desired height is reached, the hydraulic cylinder can hold the load in position. The hydraulic system maintains pressure in the cylinder, locking the piston and preventing unintended bag lowering.

Our Company

We have a first-class independent R&D platform for assembly. The forklift cylinder production workshop has 4 semi-automatic lifting cylinder assembly lines and 1 fully automatic tilting cylinder assembly line, with a designed annual production capacity of 1 million pieces; the special cylinder workshop is equipped with semi-automatic cleaning and assembly systems of various specifications, with a designed annual production capacity of 200,000 essays. It has famous CNC machining equipment, machining centers, special equipment for high-precision cylinder processing, robot welding machines, automatic cleaning machines, automatic cylinder assembly machines, and automatic paint production lines. We have more than 300 sets of critical equipment running. The optimized allocation and efficient utilization of equipment resources ensure the precision requirements of the products and meet the high standard quality requirements of the products.

|

Forklift cylinder assembly shop |

Other types of cylinder assembly shop |

Welding

Painting & coating

|

Painting & coating line |

Fully automatic water-based |

Testing

To further improve product performance, and establish the leadership position of our hydraulic cylinder in the industry, our company and zjimee jointly established a Comprehensive performance laboratory of hydraulic cylinders, hydraulic valves, and hydraulic pumps; the lab is computer-assisted testing, using electro-hydraulic control technology, the test conditions preset by computer, which improves the test accuracy and system versatility, and the experimental data.

The automatic collection is realized through the application of sensors, and the output data, such as the internal leakage and load efficiency of the cylinder or the valve, are directly processed by the computer and converted to standard units (ml/min; %). At the same time, to ensure the working safety of the hydraulic system, the state monitoring function is carried out for key performance parameters, such as “oil temperature monitoring, liquid level monitoring, filter device monitoring,” etc. Among them, the hydraulic cylinder test stand can test the performance of “load efficiency” and “internal leakage” by readings. At the same time, it is equipped with a grating ruler measuring instrument, which meets the requirements of all test items of hydraulic cylinder products in the national standard.

Our Factory

Packaging & Shipping

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Double Acting |

| Working Method: | Rotary |

| Adjusted Form: | Regulated Type |

Can double-acting hydraulic cylinders be repaired or maintained when needed?

Yes, double-acting hydraulic cylinders can be repaired and maintained when needed. Here’s a detailed explanation:

1. Inspection and Diagnosis: When a double-acting hydraulic cylinder requires repair or maintenance, the first step is to conduct a thorough inspection and diagnosis. This involves examining the cylinder for any visible damage, leaks, or signs of wear. Additionally, the hydraulic system and associated components should be checked for proper operation and potential issues. Through inspection and diagnosis, the specific problem or maintenance requirement can be identified.

2. Seal Replacement: One of the most common maintenance tasks for double-acting hydraulic cylinders is seal replacement. Seals, such as piston seals and rod seals, are critical components that prevent fluid leakage and maintain system integrity. Over time, seals can wear out or become damaged, leading to leaks and reduced performance. By replacing worn or damaged seals, the cylinder’s functionality can be restored.

3. Component Repair or Replacement: Depending on the nature and extent of the issue, specific components of the double-acting hydraulic cylinder may need repair or replacement. This can include repairing or replacing damaged pistons, rods, glands, or other internal parts. In cases where the damage is extensive or the component is beyond repair, a complete replacement may be necessary.

4. Fluid and Filter Maintenance: Proper fluid and filter maintenance is essential for the optimal performance and longevity of hydraulic cylinders. Regular fluid checks, fluid level adjustments, and fluid replacements are part of routine maintenance. Similarly, filters should be inspected and replaced as needed to prevent contamination and ensure the cleanliness of the hydraulic fluid.

5. Lubrication: Lubrication is vital for the smooth operation of double-acting hydraulic cylinders. Lubrication points, such as pivot points and sliding surfaces, should be regularly lubricated with the appropriate lubricant. This helps reduce friction, wear, and potential damage to the cylinder components.

6. Testing and Calibration: After repairs or maintenance activities, it is important to perform testing and calibration to ensure that the double-acting hydraulic cylinder is functioning correctly. This may involve checking for proper operation, verifying the cylinder’s force output, and conducting leakage tests. Testing and calibration help validate the effectiveness of the repair or maintenance work.

7. Preventive Maintenance: Implementing a preventive maintenance program is highly recommended to proactively address potential issues and extend the lifespan of double-acting hydraulic cylinders. This includes regular inspections, scheduled maintenance tasks, and adherence to manufacturer-recommended service intervals. Preventive maintenance helps identify and address problems before they cause significant damage or system failures.

8. Professional Assistance: In complex repair or maintenance situations, or when specialized knowledge is required, seeking professional assistance is advisable. Hydraulic system experts or certified technicians can provide the necessary expertise and ensure that repairs and maintenance are conducted safely and effectively.

By performing regular maintenance and addressing repairs promptly, double-acting hydraulic cylinders can be kept in optimal condition, ensuring their reliable operation and longevity.

Can double-acting hydraulic cylinders be used in automotive repair and maintenance?

Yes, double-acting hydraulic cylinders can be extensively used in automotive repair and maintenance. Here’s a detailed explanation:

1. Lifting and Lowering Vehicles: Double-acting hydraulic cylinders are commonly employed in automotive lifts and jacks for lifting and lowering vehicles. These cylinders provide the necessary force to raise vehicles off the ground, allowing mechanics to access the underside of the vehicle for repairs, maintenance, or inspections. The bidirectional force generation of double-acting cylinders enables precise control over the lifting and lowering process, ensuring the safety and stability of the vehicle during automotive tasks.

2. Pressing and Clamping: Automotive repair often involves pressing or clamping components together during assembly or disassembly processes. Double-acting hydraulic cylinders can be used in hydraulic presses or clamping devices to provide the required force. By supplying hydraulic pressure to one side of the cylinder, the piston extends, applying force to press or clamp components together. By supplying pressure to the other side, the piston retracts, releasing the pressure. This capability allows for precise and controlled pressing or clamping operations in automotive repair and maintenance.

3. Brake and Suspension System Maintenance: Double-acting hydraulic cylinders play a vital role in brake and suspension system maintenance. For example, when bleeding brake lines, a hydraulic cylinder can be used to pressurize the brake system and force the air bubbles out of the brake fluid. Similarly, in suspension system maintenance, hydraulic cylinders can be employed to compress or decompress suspension components, facilitating repairs or replacements. The precise force control offered by double-acting cylinders ensures accurate and effective maintenance of these critical automotive systems.

4. Engine Hoists and Tilters: Engine repair and maintenance often require lifting, tilting, or removing heavy engines from vehicles. Double-acting hydraulic cylinders are utilized in engine hoists and tilters to provide the necessary force for these tasks. The cylinders can be integrated into lifting mechanisms, allowing controlled lifting and tilting of engines for access to various components or for engine removal and installation. The precise force application of double-acting cylinders ensures the safe handling of heavy engine assemblies.

5. Wheel Alignment and Balancing: Double-acting hydraulic cylinders are also used in wheel alignment and balancing equipment. These cylinders provide the force required to adjust wheel angles and balance tires accurately. By applying precise force to the wheel clamps or alignment mechanisms, the cylinders enable mechanics to align wheels correctly and achieve balanced tire rotations, ensuring optimal vehicle performance, safety, and tire longevity.

Given their applications in lifting and lowering vehicles, pressing and clamping operations, brake and suspension system maintenance, engine hoisting and tilting, as well as wheel alignment and balancing, double-acting hydraulic cylinders are indispensable in automotive repair and maintenance. Their precise force control and versatility make them valuable tools for mechanics and technicians in the automotive industry.

Can you explain the purpose and applications of double-acting hydraulic cylinders?

The purpose of double-acting hydraulic cylinders is to generate force in both directions of their stroke, allowing for precise control and versatility in various applications. Here’s a detailed explanation of their purpose and applications:

1. Purpose: Double-acting hydraulic cylinders are designed to provide bidirectional force, meaning they can push and pull loads. This capability allows for a wide range of tasks that require controlled linear force, such as lifting, pushing, pulling, clamping, bending, and holding. The ability to generate force in both the extension and retraction strokes makes double-acting cylinders highly efficient and versatile.

2. Applications: Double-acting hydraulic cylinders find applications in numerous industries and sectors where controlled force is required. Some common applications include:

– Manufacturing and Machinery: Double-acting cylinders are widely used in manufacturing and machinery industries for tasks such as press operations, material handling, assembly lines, robotics, and automation systems. They provide the necessary force to move and position components, operate hydraulic presses, and perform precise tasks with controlled motion.

– Construction and Earthmoving: In construction and earthmoving equipment, double-acting hydraulic cylinders are utilized in applications such as excavators, backhoes, loaders, bulldozers, and cranes. They enable lifting and lowering of heavy loads, extending and retracting booms and arms, and controlling the movement of various hydraulic attachments.

– Mining and Extraction: Double-acting hydraulic cylinders play a crucial role in mining operations for tasks like rock drilling, roof bolting, ore extraction, and material handling. They are used in equipment such as hydraulic shovels, loaders, and crushers to provide the necessary force for excavation, transportation, and processing of minerals and ores.

– Agriculture and Farming: In the agricultural sector, double-acting hydraulic cylinders are employed in machinery and equipment such as tractors, harvesters, sprayers, and loaders. They enable functions like lifting and lowering of implements, controlling hydraulic systems for precise operation, and powering hydraulic attachments such as plows, mowers, and loaders.

– Automotive and Transportation: Double-acting hydraulic cylinders are utilized in various automotive and transportation applications. They are found in vehicle suspension systems, steering mechanisms, hydraulic brakes, dump trucks, garbage trucks, and lifting platforms. These cylinders provide the force necessary for controlled movement, stability, and safety.

– Aerospace and Aviation: In the aerospace and aviation industries, double-acting hydraulic cylinders are used in aircraft landing gear systems, wing flaps, control surfaces, and cargo doors. They provide the force required for smooth and controlled movement, ensuring safe and efficient operation of aircraft.

– Marine and Offshore: Double-acting hydraulic cylinders are employed in marine and offshore applications such as ship steering systems, hatch covers, cranes, winches, and offshore drilling equipment. They enable precise control of movements and operations in challenging marine environments.

These are just a few examples of the diverse applications of double-acting hydraulic cylinders. Their ability to generate force in both directions, combined with precise control and versatility, makes them essential components in various industries where controlled linear force is required.

editor by CX 2023-10-19