Product Description

Product Description

High pressure electric hydraulic cylinder is powered by high pressure electric oil pump, the function for oil pressure rebound, overflow, it is designed a safe protect pressurizer, it can protect emergent over pressure, especial construction can protect jack.

Hydraulic cylinder can bear partial loading is 5% of rated pressure. High pressure alloy cylinder is very durable, especially in the larger project, it is easily to be operated and control. It can be used for lifting heavy machine, bridge project, hydraulic engineering, harbour construction and other equipment. It has large output, light weight, remote control and other advantages, it can match with our high pressure oil pump, it can reach jack, push, pull and extrusion and kinds of working.

Product Show

Single acting hydraulic cylinder

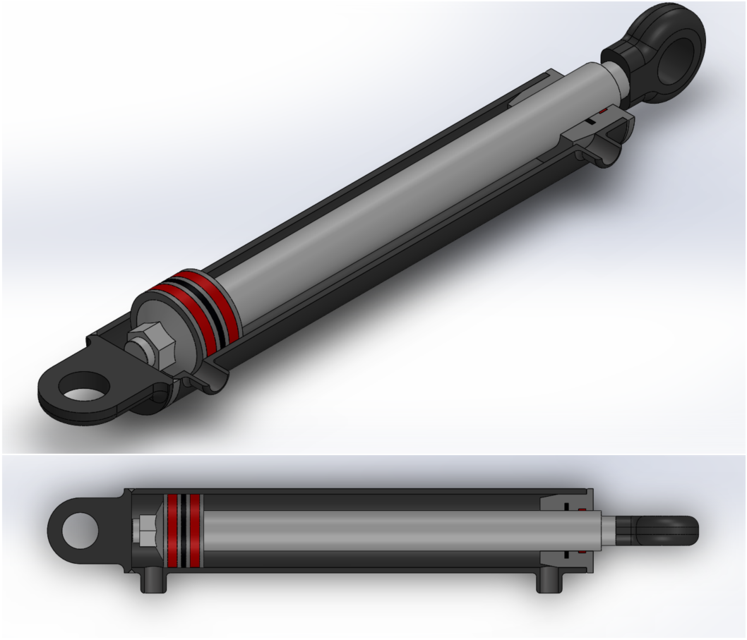

Double acting cylinders

Product Details

Product Parameters

| Model | Tonnage T |

Stroke B-A mm |

Own body height A mm |

Extend height B mm |

Outer diameter of oil cylinder mm |

Dimension of plunger mm |

Dimension of oil pump mm |

Weight kg |

Pressure | Recommend electric oil pump |

| STQ100-100 | 100 | 100 | 250 | 350 | 180 | 100 | 140 | 58 | 63MPA 63MPA 63MPA 63M |

|

| STQ100-160 | 160 | 310 | 470 | 63 | ||||||

| STQ100-200 | 200 | 350 | 550 | 78 | ||||||

| STQ100-300 | 300 | 450 | 750 | 96 | ||||||

| STQ100-500 | 500 | 650 | 1150 | 130 | ||||||

| STQ150-100 | 150 | 100 | 260 | 360 | 219 | 125 | 180 | 58 | ||

| STQ150-160 | 160 | 320 | 480 | 69 | ||||||

| STQ150-200 | 200 | 360 | 560 | 86 | ||||||

| STQ150-300 | 300 | 460 | 760 | 103 | ||||||

| STQ150-500 | 500 | 660 | 1160 | 255 | ||||||

| STQ200-100 | 200 | 100 | 285 | 385 | 240 | 150 | 200 | 96 | ||

| STQ200-160 | 160 | 345 | 505 | 103 | ||||||

| STQ200-200 | 200 | 385 | 585 | 116 | ||||||

| STQ200-300 | 300 | 485 | 785 | 161 | ||||||

| STQ200-500 | 500 | 685 | 1185 | 221 | ||||||

| STQ320-100 | 320 | 100 | 310 | 410 | 330 | 180 | 250 | 196 | 1.5KW 3KW 4KW 5.5KW |

|

| STQ320-160 | 160 | 370 | 530 | 240 | ||||||

| STQ320-200 | 200 | 410 | 610 | 258 | ||||||

| STQ320-300 | 300 | 510 | 810 | 311 | ||||||

| STQ320-500 | 500 | 710 | 1210 | 456 | ||||||

| STQ400-100 | 400 | 100 | 355 | 455 | 380 | 200 | 290 | 198 | 3KW 4KW 5.5KW 7.5KW |

Application

Hydraulic cylinder can bear partial loading is 5% of rated pressure. High pressure alloy cylinder is very durable, especially in the larger project, it is easily to be operated and control. It can be used for lifting heavy machine, bridge project, hydraulic engineering, harbour construction and other equipment. It has large output, light weight, remote control and other advantages, it can match with our high pressure oil pump, it can reach jack, push,pull and extrusion and kinds of working.

Company Profile

HangZhou Sinogrout Machinery Co.,Ltd. is an enterprise specializing in research and development of signle/double acting hydrulic jacks, Flange hydraulic jack, Lock Nut hydraulic jack, Thin hydraulic Jack, Hollow hydraulic jack and electric hydraulic oil pump. Manufacturing, processing and sales, relying on professional level and mature technology companies continue to provide users around the world with intelligent solutions of high quality, advanced technology and perfect service. “Quality first, reputation first” purpose, with scientific management means and strong technical force, we will constantly deepen reform, innovate mechanism, adapt to market and develop in an all-round way. We sincerely welcome new and old customers from abroad to visit and negotiate cooperation.

Bulk Stock And Delivery

FAQ

Q1: How to make payment?

A1: Paypal, Western Union, Moneygram or T/T transfer.

Q2: How long does it take to process orders?

A2: It usually takes 10-14 working days to process most orders for no stock, if stock available, only take 2- 3 working days.

Q3: What is the packing method?

A3: For small piece, we use carton box; for big piece, we use exporting grade plywood case.

Q4: How to ship?

A4: Sea freight, Air freight or International express(DHL, FEDEX,UPS…) all are available.

Q5: What is the warranty?

A5: 12 months against B/L date.

| After-sales Service: | Yes |

|---|---|

| Warranty: | 1 Year |

| Type: | Hydraulic Jack |

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does a double-acting hydraulic cylinder handle variations in environmental conditions?

A double-acting hydraulic cylinder is designed to handle variations in environmental conditions effectively. Here’s a detailed explanation:

1. Sealing Mechanism: Double-acting hydraulic cylinders are equipped with sealing mechanisms that help protect the internal components from environmental elements. The cylinder is typically sealed with high-quality seals and gaskets that prevent the ingress of contaminants such as dirt, dust, and moisture. This sealing mechanism helps maintain the integrity of the hydraulic system and ensures reliable operation even in challenging environmental conditions.

2. Corrosion Resistance: Double-acting hydraulic cylinders are often constructed from materials that offer excellent corrosion resistance. Common materials used include stainless steel, chrome-plated steel, or other corrosion-resistant alloys. These materials are chosen to withstand exposure to humid or corrosive environments, such as marine applications or outdoor equipment exposed to weather conditions. The corrosion resistance of the cylinder components ensures its durability and performance over an extended period, even in harsh environmental conditions.

3. Temperature Tolerance: Double-acting hydraulic cylinders are designed to handle variations in temperature effectively. The internal components, such as seals and fluids, are selected to withstand a broad temperature range. Specialized seals and hydraulic fluids can be used to maintain proper performance in extreme heat or cold. Additionally, the cylinder’s design may incorporate temperature compensation features to accommodate thermal expansion and contraction, ensuring consistent and reliable operation across different temperature conditions.

4. Contaminant Filtration: Hydraulic systems that utilize double-acting cylinders often incorporate filtration systems to remove contaminants from the hydraulic fluid. Filtration helps prevent the accumulation of particles that can cause wear and damage to the cylinder components. By maintaining clean hydraulic fluid, the cylinder can operate optimally and handle variations in environmental conditions without compromising performance or longevity.

5. Protective Coatings: In certain applications where additional protection is required, double-acting hydraulic cylinders can be coated with protective materials. These coatings provide an extra layer of defense against environmental factors, such as chemical exposure or abrasive particles. Protective coatings can enhance the cylinder’s resistance to wear, corrosion, and other detrimental effects caused by specific environmental conditions.

6. Compatibility with Environmental Sealing: Depending on the specific application and environmental conditions, double-acting hydraulic cylinders can be integrated with environmental sealing measures. For example, in marine or underwater applications, the cylinder can be designed with additional sealing features to prevent water ingress. Such sealing measures ensure that the cylinder operates reliably and safely in challenging environments.

By incorporating sealing mechanisms, corrosion-resistant materials, temperature tolerance, contaminant filtration, protective coatings, and compatibility with environmental sealing, double-acting hydraulic cylinders can effectively handle variations in environmental conditions. This robust design allows them to operate reliably and maintain performance in diverse applications and challenging environments.

Can double-acting hydraulic cylinders be used in agricultural machinery for various tasks?

Yes, double-acting hydraulic cylinders are commonly used in agricultural machinery for a variety of tasks. Here’s a detailed explanation:

1. Lifting and Lowering Implements: Agricultural machinery often requires the lifting and lowering of implements such as plows, cultivators, and seeders. Double-acting hydraulic cylinders can provide the necessary force to raise and lower these implements smoothly and efficiently. By supplying pressurized hydraulic fluid to one side of the cylinder, the implement is lifted, and by supplying fluid to the other side, it is lowered. The bi-directional force generation of double-acting cylinders allows for precise control over the height and position of the implements, enabling efficient agricultural operations.

2. Tilting and Positioning: Double-acting hydraulic cylinders can also be used for tilting and positioning tasks in agricultural machinery. For example, in a front-end loader or a combine harvester, hydraulic cylinders are employed to tilt the loader bucket or the cutting platform, allowing for easy loading or harvesting on uneven terrain. The cylinders provide the necessary force to adjust the angle and position of the equipment, enhancing productivity and maneuverability.

3. Steering and Braking: Agricultural machinery, such as tractors and self-propelled harvesters, requires effective steering and braking systems for safe and precise operation. Double-acting hydraulic cylinders can be utilized in these systems to control the movement of steering mechanisms or braking mechanisms. By converting hydraulic pressure into mechanical force, the cylinders enable responsive steering and reliable braking, ensuring operator control and safety in various agricultural tasks.

4. Actuating Hydraulic Valves: Agricultural machinery often incorporates hydraulic systems with multiple valves for controlling the flow of fluids to different components. Double-acting hydraulic cylinders can actuate these valves, allowing for precise control over the functions of the machinery. By extending and retracting the cylinder’s piston, operators can open or close specific valves, regulating the flow of hydraulic fluid and directing it to the desired components or functions.

5. Load Handling and Manipulation: Agricultural machinery frequently involves load handling and manipulation tasks, such as baling, lifting and transporting heavy loads, or operating hydraulic arms for loading and unloading materials. Double-acting hydraulic cylinders provide the necessary force for these tasks, enabling efficient load handling and manipulation. The cylinders can be integrated into lifting mechanisms, arms, or other load-bearing structures, allowing for controlled lifting, lowering, and holding of various agricultural loads.

Given their capabilities in lifting and lowering implements, tilting and positioning, steering and braking, actuating hydraulic valves, as well as load handling and manipulation, double-acting hydraulic cylinders are widely used in agricultural machinery for various tasks. Their versatility, power, and precise control make them essential components in modern agricultural equipment.

What are the key components and design features of a double-acting hydraulic cylinder?

A double-acting hydraulic cylinder consists of several key components and incorporates specific design features to enable its functionality. Here’s a detailed explanation:

1. Barrel: The barrel, also known as the cylinder tube, is a cylindrical structure that provides the main body of the hydraulic cylinder. It is typically constructed from high-strength, durable materials such as steel or aluminum to withstand the hydraulic pressure and external forces.

2. Piston: The piston is a cylindrical component that divides the interior of the hydraulic cylinder into two chambers—the cap-end chamber and the rod-end chamber. It is usually made of materials like steel or cast iron. The piston is designed to fit tightly within the barrel, forming a seal to prevent hydraulic fluid leakage between the chambers.

3. Rod: The rod, also known as the piston rod or plunger, is connected to the piston and extends through one end of the hydraulic cylinder. It provides the external connection point for attaching loads or other mechanical components. The rod is typically made of high-strength steel to withstand the forces applied during operation.

4. Seals: Seals are essential components in double-acting hydraulic cylinders to maintain the separation of the two chambers and prevent hydraulic fluid leakage. There are various types of seals used, including piston seals, rod seals, and wiper seals. These seals are typically made of materials such as rubber or polyurethane and are designed to provide an effective barrier against fluid leakage.

5. Hydraulic Ports: A double-acting hydraulic cylinder has two hydraulic ports—one connected to the cap end and the other connected to the rod end of the cylinder. These ports enable the inflow and outflow of hydraulic fluid to and from the respective chambers. The hydraulic ports are typically equipped with fittings or connectors to facilitate the connection of hydraulic hoses or pipes.

6. Mounting Options: Double-acting hydraulic cylinders are designed with various mounting options to facilitate their installation and integration into hydraulic systems. Common mounting options include flange mounts, trunnion mounts, clevis mounts, and foot mounts. These mounting options provide flexibility in connecting the hydraulic cylinder to other components or structures.

7. Cushioning Mechanism: Some double-acting hydraulic cylinders incorporate cushioning mechanisms to dampen the impact and decelerate the piston at the end of its stroke. This helps to reduce shock, minimize noise, and prolong the lifespan of the cylinder. Cushioning mechanisms can include adjustable cushions, fixed cushions, or hydraulic cushioning systems.

8. Surface Coatings: Depending on the application and operating conditions, double-acting hydraulic cylinders may feature surface coatings to enhance their performance and durability. Common surface coatings include chrome plating or other corrosion-resistant coatings to protect against wear, corrosion, and environmental factors.

These key components and design features work together to enable the functionality and reliability of double-acting hydraulic cylinders. They allow for the controlled extension and retraction of the piston, the generation of bidirectional force, and the efficient transmission of hydraulic power.

editor by CX 2023-10-16